How to choose putty on wood?

With the help of putty on wood, you can eliminate various defects and surface nerves. In addition, putty can improve the characteristics of lumber and extend its life. Apply this composition is necessary before finishing the processing of wood. Manufacturers of building materials offer many different types of wood fillers. Features of the choice of putty on wood will be discussed in more detail in this article.

Application features

Spackling work can be carried out with any type of wood, with any degree of deterioration of the material.Wood putty is mainly to eliminate defects on the surface, but this is not the main function of wood putty.

Among the advantages of using the mixture are the following:

- Hydrophobic properties. The putty prevents the penetration of moisture into the wood structure.

- The mixture can be used to seal deep cracks, eliminate damage from poor woodworking, and restore wood decorative elements.

- Parquet mortar has a high level of adhesion. The putty applied to the floor easily penetrates the cracks and hides surface defects.

- After the mixture is completely dry, it becomes transparent and does not change the natural look of the wood structure.

Kinds

There are many different varieties of putty on wood, which differ in some properties, color and composition.

The composition of the following types of mixtures:

- Gypsum.

- Acrylic. Acrylic blend allows you to extend the life of the wooden structure. The positive qualities can also be attributed to a small price, good adhesion rates, a large assortment, and a short drying time.Quick-drying heat and moisture resistant acrylic putty is great for processing wooden floors.

- Water resistant. Variety of acrylic blends. The composition of waterproof solutions, in addition to acrylic, includes some resins and latex. It is applied both to internal, and to external works.

- Non-shrink Differ in lack of shrinkage of material and good indicators of adhesion. Suitable for furniture and new smooth floors.

- Nitro spackling (solvent based). The composition of such mixtures include solvents. They are resistant to the effects of household chemicals and moisture.

- Glue. Such materials include mixtures made by hand on the basis of glue.

- Latex or polymer. Polymer and latex putty easily fall on the surface, forming an even layer. Differ in high speed of drying. The disadvantages include high cost. Perfect for parquet processing.

- Oily. Made on the basis of natural oils. Possess good durability and moisture resistance. The disadvantage of this solution is a long drying time.

- Oil-adhesive.

- AlkydThe mixture includes alkyd resins. Alkyd putty is elastic and viscous. It is used mainly as a coating for painting enamels. Also on such a coating is good lacquer.

- Epoxy. Epoxy putty has a plastic structure and a high level of adhesion. Such a solution can be used as a base coat or for finishing.

In shades, colorless and colored compositions are distinguished. Colorless putty hides various damages on the wood surface. With this solution, you can restore the old floor. For the formation of the base layer thickness applied putty can be from two millimeters to several centimeters. For finishing it is necessary to apply a layer from one to five millimeters thick.

Colored furniture putty is used for the restoration and is selected in accordance with the shade of wood. With this mixture, fill and level the damage on the surface, resulting from the long operation of the wooden structure.

Compositions of own production

Products of well-known manufacturers are often expensive.To save money, you can make a putty yourself. If you pick up good ingredients, then the quality of the home-made material will not yield to store mixes.

You can make your own adhesive or oil-adhesive mixtures.

Before you start making putty, you need to examine the proven recipes and choose the most appropriate way:

- The most popular method of making putty solution involves the use of chalk and white glue as the main components. The method of manufacture is reduced to the mixing of chalk and PVA glue until smooth. The resulting mass should resemble sour cream. The disadvantage of this solution is the drying time (twenty-four hours). If you need putty to eliminate cracks in the wood, then you need to add a little fine sawdust to the mixture.

- There is another simple recipe for putty using chalk as a main ingredient. Chalk must be mixed with acrylic varnish to obtain a pasty mass. If the paste is too thick, add some water.The drying time of such putty is twelve hours. In order to use such a solution for leveling surfaces, it is also recommended to add sawdust to it.

There are also the most complex recipes for the production of putty mixtures at home.

To prepare the mixture for painting will require the following components:

- turpentine oil (turpentine) - 70 grams;

- flax seed oil - 290 grams;

- gelatin - 30 grams;

- pumice powder or perlite powder - 40 grams;

- casein - 30 grams;

- sodium tetraborate (borax) - 22 grams;

- ammonia (18%) - 28 grams;

- water - about 350 grams.

The first step is to mix the turpentine and linseed oils with pumice or perlite powder. In the resulting solution, add water and mix thoroughly until smooth, then add the remaining components. The finished mixture should be heated to 90 degrees and stir until smooth.

Manufacturers

In order not to be mistaken when buying putty, it is worth choosing products of famous manufacturers:

- In Russia, the company is one of the three leaders in the production of paint and varnish products. VGT. The company has been supplying the Russian market with a wide range of high quality building materials since 1992. All products of the company have the appropriate quality certificates.

- Company Parade is a major manufacturer of finishing materials. The main feature of the products of this enterprise is environmental friendliness. Finishing materials are made only from high-quality imported raw materials according to the latest technologies. Products undergo strict quality control at every stage of the production process.

All paints and varnishes have quality certificates and can be used in medical institutions. Parade - the first organization in Russia, which has the right to use the sign "100% Eco Quality"

- Factory "Rainbow" is a leader in the manufacture and sale of paints and varnishes. Products of this company are widely demanded in different regions of the world. In addition to high quality products, LC "Rainbow" offers a high level of customer service. Employees of the company are ready to develop a new product, in accordance with the specific requirements of the customer.

- Company "Olympus" sells its products in Russia and the CIS countries, successfully competing with well-known Russian and foreign brands. Paintwork materials are made using the most modern equipment from high quality European raw materials. Employees of the organization strictly control the quality of raw materials and finished products, as well as actively implement the latest technology in the production process.

- Company Lacra manufactures paint products in Europe and Russia according to modern Western technologies. All products manufactured by these enterprises comply with global quality standards. The Lakra company is one of the three leading manufacturers of paint and varnish products in Russia.

- Among other major manufacturers of fillers for wood can be identified: Bostik, PHZ, Tikkurila, Smes, Synteco. The products of these companies are also of high quality and have a great demand in the market of finishing materials.

Reviews

After reviewing the leaders among the companies for the production of putty, you need to study the reviews on the most popular products. This will help make the right choice and buy quality material.

Acrylic filler for wood "Extra" company VGT. This material has only positive customer feedback.

Consumers distinguish the following advantages of the product:

- high quality;

- low cost;

- lack of smell;

- elasticity;

- water resistance;

- frost resistance;

- ease of application;

- quick drying

Buyers do not note serious shortcomings of this material.

There are the following minor drawbacks:

- material is produced in containers of small volumes only;

- putty brightens a little when dried;

- short shelf life.

Moisture resistant putty on the company Parade also has a lot of positive feedback. Buyers appreciated the high quality of the material, ease of application and short drying time. However, there are negative reviews about this material. The disadvantages include a high level of shrinkage, fast drying on the spatula during the finishing works and cracking of the coating.

Consumers emit putty wood from the company "Lacra". Reviews say that this material is easy to use, odorless and dries quickly.

However, some buyers doubt the safety of putty, as it contains lead, which can adversely affect health.

Which one to choose?

When buying any finishing material, the consumer first of all expects to become the owner of a high-quality product. High-quality wood filler should meet certain criteria.

Select the main ones:

- the mixture should be homogeneous;

- putty coating should be easy to sand;

- high adhesion level;

- no impurities should be present in the composition;

- short drying time;

- ease of application;

- the dry mixture should consist of fine particles so that the ready putty will fall in a thin and durable layer;

- environmental friendliness.

High quality putty is not the only selection criterion.

To choose the right mixture, it is important to pay attention to the following factors:

- Place of work: for exterior or interior decoration.

- Color blend. Manufacturers produce puttying a variety of shades of natural wood: pine, wenge, beech, oak, cherry, etc.Having picked up a mixture of a suitable color, the treated surface can not be painted and immediately treated with varnish. White putty is used for tinting or for leveling the surface.

- Appointment of work: basic or finishing.

- The purpose of the work. In this case, it is important what result you want to obtain: surface treatment for painting for better adhesion, masking defects, repairing cracks and leveling, restoration, improving the qualities and certain characteristics of wood.

Recommendations for application

As with all other types of finishing works, a number of preparatory activities should be carried out before the putty of the wooden covering. First of all, it is necessary to prevent the likelihood of contamination from the putty mixture in the room in which the finishing will take place. If you need to putty the walls, then the window frames, the door, the furniture, the floor surface, must be covered with plastic wrap.

You must also take care of your own safety. Some putty mixtures have a sharp, unpleasant smell.

It is possible to protect the organs of the respiratory system with a mask or respirator.You should wear gloves on your hands as the putty dries the skin.

Next, you need to prepare the necessary tools.

For finishing work you may need:

- wide and narrow iron spatula;

- a bucket or any other container for the mixture;

- paint brush, roller or construction gun (suitable for applying liquid mixtures);

- sandpaper;

- construction scraper;

- steel wire brush;

- trowel for plastering;

- sponge.

Before you start applying putty on wood, the surface must be prepared for the finish. If the tree has already applied a layer of paint or plaster, it is desirable to clean it, otherwise the putty may peel off from such a surface. To remove the old coating, you can use a building dryer, solvents or a metal brush.

When working with a solvent, you must adhere to the following rules:

- the tool should be applied evenly over the entire surface;

- after application, you must wait fifteen minutes;

- swollen paint must be removed with a spatula;

- if the procedure is carried out indoors, the room must be well ventilated.

If on the surface there are metal parts from nails or other elements, they must be enameled. This will prevent the appearance of rust in the further exploitation of the wooden structure.

To improve the adhesion of materials, wood must be primed. In addition, most primers contain antiseptic ingredients. Wood treated with this composition will be protected from fungus, mold and moisture. It is desirable that the composition of the primer was similar to the composition of the putty material.

Three layers of primer must be applied to the surface, then let it dry thoroughly. The exact time of drying of the mixture can be found on the packaging of the primer. After complete drying of the wood, you can begin the process of putty.

Before applying the putty, you must carefully inspect the surface for cracks. In case of detection of defects, it is necessary to seal up the slots with a putty. It is better to cover the most problematic areas with large defects with self-adhesive tape serpianka, which will reduce the consumption of putty during finishing and prevent cracking.

After removal of defects on the surface, you can proceed to the main finish.

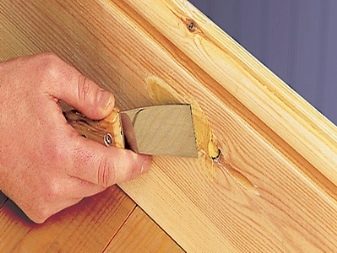

When applying putty to the surface, it is worth adhering to the following algorithm:

- With the help of a narrow iron spatula putty is spread on a wide tool.

- The mixture is applied to the surface in a diagonal motion from top to bottom.

- The thickness of the first layer should not exceed three millimeters.

- After applying the first layer on the surface will strip. When the putty dries, the defects are removed with sandpaper.

- The thickness of the last layer should not be more than one and a half millimeters.

- With favorable temperature conditions, the putty dries for about a day. It is worth considering that this is the maximum drying time.

In order for the result of the work done to meet expectations, it is necessary to follow certain rules.

Basic recommendations for applying putty:

- When carrying out finishing work, it is important that the air temperature was not lower than five degrees Celsius. Otherwise, the mixture thickens, making it difficult to penetrate into the gap.

- Before the main treatment, all recesses in the surface must be sealed.

- It is advisable to use a stainless steel spatula.

How to seal the gap in the furniture with putty, see below.