The rule for plaster: the choice of tools for finishing

The rule is a perfect flat rail with which to level the surface when finishing the walls with plaster. Also, the tool is necessary for monitoring the evenness (quality) of the work performed.

Species

The rule for finishing work with plaster is a flat batten made of wood up to 2 m long. The main disadvantage of such a tool is the tendency to deform when exposed to negative moisture. This problem can be eliminated by using, for example, a special impregnation for wood - linseed oil.

The rule of the modern type is already a 3-meter profile up to 12 cm wide, made of aluminum. This light metal rule will not be subjected to deformation, respectively, such a tool is very durable.

For example, the h-shaped rule can be equipped with a hydraulic level embedded inwards, this greatly simplifies the workflow produced by yourself. This tool can also be used for other works in which there is a need to use a long level.

To check the wall for evenness, a rule is applied to it, the plane is examined by the resulting gap between them and the curvature is judged. A size of 1.5 cm is considered a tolerance.

This type of verification should be carried out over the entire plane. The construction level is also used to check the correctness of the slope of the walls.

Smoothing plaster rule

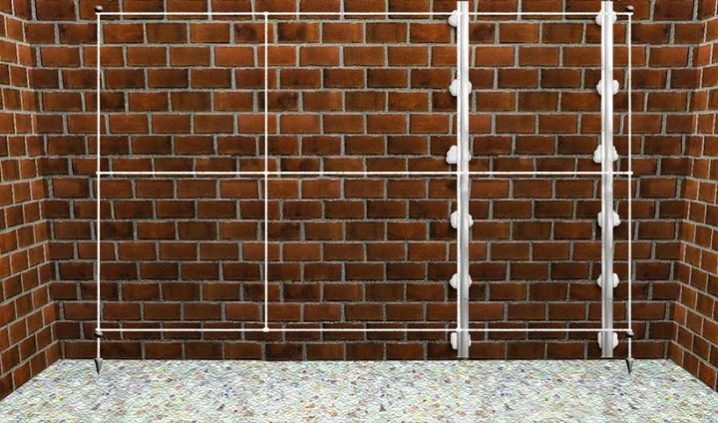

Adjust the plaster by cutting off excess residues using the rule. The rule should slide along specially fixed rails, whose name is beacons. Such lighthouses are set in advance. These slats should be in a perfectly flat plane. The existence of lighthouses and their competent installation will allow for a perfect plastering. The most popular method of finishing the surface is considered to be plastering under the rule.

Lighthouses

Such approximate slats fix not too tightly in the corners and near the door and window slopes. The gap between them will depend on the size of the width of the pier, the distance should not be less than the length of the rule itself for adjusting the plaster layer.

Such lighthouses differ in design and material of manufacture:

- Wooden lighthouses. Wood has one significant disadvantage - inconstancy of geometric forms. Wood is deformed too quickly, therefore it is too rarely used for wet work.

- Metal beacons. In the role of steel lighthouses serves ordinary tin profile. Such a tool will not swell under the influence of water. Nevertheless, it also has disadvantages - a thin, easily bent profile is more expensive than ordinary wooden slats.

Alignment of the plaster layer by the rule of approximate auxiliary beacons is usually performed using a profile. There are different types of landmarks:

- Brick or ceramic tile. Landmark can be small pieces of brick, stone, chipped ceramic tiles. They are fixed to the wall in the given planes.Of course, this is not a very convenient solution, but you can still use tiles or bricks when installing solid rails is impossible.

- Building mixture. Fragments of the solution are installed throughout the working area, fixation is carried out at a distance convenient for work. Such a complicated workflow may affect the quality of plastering. Accordingly, it can only be used in areas that do not have high requirements - a garage or an outbuilding.

Sometimes also used nails with a tight rope. This option is a non-professional solution. It is considered the easiest to plaster with the help of the rule with the use of guides.

Lighthouses fixation

You should examine the entire room before fixing the landmark. It is necessary to identify whether the walls are deformed, whether there is a bias, how accurate the corners of the room are. The most important step is considered to be plastering the corners of the room. Geometric distortion is very noticeable in the corners; every corner of the room must remain absolutely straight. First, the walls need to be examined with a plumb, so you can find a point, which becomes the future reference point.

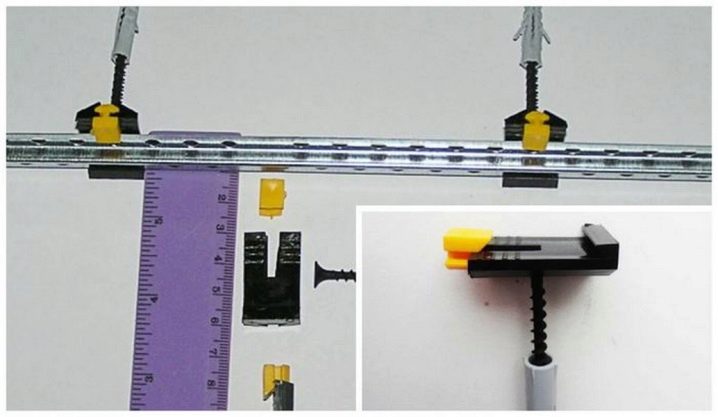

Further in the walls you need to screw the screws, thanks to which it will be possible to install the beacons as even as possible. Screws should be screwed in first in the upper corners. Using a vertical level or plummet, the same is done for the lower corners of the room.

The lighthouses are oriented to the heads of the screws already installed in terms of the screw level:

- Metal profile superimposed on the screws themselves.

- Wooden indicative lighthouses are positioned close so that their plane fully complies with the area of the screw cap.

Reiki must be fixed with a solution; this should be done along the entire line of the established level with a kind of “lapses”. For such an operation it is better to use a notched trowel. Metal profile rails made of tin material are very flexible, respectively, performing this operation for the first time, it is better to lean on the rail for 6 screws. Additional screws for stability can be screwed at a distance of 50 cm.

After curing the solution must be filled under the guides of the existing void. To achieve rigid fixation, you need to "smear" guides on the sides.After placing two landmarks near the corners, you can proceed to fixing additional rails. The need for this may arise only because of the peculiarities of the length of the wall.

2 screws are screwed into the wall surface between the corner and the rail itself to fix the rope. The rope should be tightly pressed against the rail. After the done operation, you can install the guides in any quantity without the use of level and hard work. For fixation, instead of mortar, you can use the mixture that will be needed when plastering the room. You can apply a gypsum-containing mixture, it will speed up the process of work, because gypsum is a rapidly hardening material.

In this case, the thread can be tightened above the rack level. This option is timely when using hard beacons, at the moment of indentation they do not bend. Accordingly, it is better to apply the rule for plastering, which is applied to the lighthouse and pressed with a pressure on its entire length. In this case, you should stretch the rope at a certain distance from the wooden slats, this gap should be equal to the width of the rule itself.

Laser fixing

The use of a construction laser will greatly facilitate the workflow: for a start, they usually put a risk on the rule (drawing a line with an ordinary pencil is considered sufficient, it will perfectly stick on aluminum). The laser should be installed in such a way that it retreats from the orienting point by the distance of the width of the fragment outlined earlier.

Thus, when the guide is pressed in, one should try to combine the line and plane of the building laser outlined in the fragment. Solving the issue in a similar way, you do not need to tighten the extra ropes and engage in screwing screws.

Plastering

Plastering under the rule will consist of several layers - splashing, primer and nakryvka. Spray - applying the first layer with a solution with a consistency resembling sour cream to get a better grip with the plane of the walls.

With almost complete drying of the first layer, the main primer is applied. You need a spatula or a trowel to throw the solution on the surface itself. At the same time, the solution needs to be thrown so that a coating with surplus is obtained. Throw a solution better spans - fragments on the walls between the landmarks. To begin to plaster the walls between the lighthouses, the rule is from the floor, starting from the very bottom.

After full coverage of the span, begin alignment. To do this, the rule is applied to the wall horizontally, for a stop at the edges there are beacons that limit the working area. The force is directed from the bottom up.

If there are gaps or dents on the plastered surface after smoothing, you need to throw in some more solution in order to follow the rule again. After that, get a perfect flat surface.

It is necessary to take into account the existing features in working with such an auxiliary tool:

- Butt rule for trimming excess remove remnants of plaster, cleaning the surface. The tool should not be pressed with the wide side so as not to bend the rule, the deformed structure can make the surface of the walls uneven. The resulting plane will resemble too visible vertical panels that will be visible under the wallpaper layer.

- When eliminating surplus, you can work as a dry rule.At the end of the whole process, it will be more correct to wet the tool in order to get the greatest smoothness.

- The aluminum rule is very flexible, so it is so easy to deform or bend. When working with such an aluminum rule, it is not necessary to allow the solution to harden on the surface of the instrument. It should periodically flush the rule.

The dried mixture should be cleaned; hard tools should be used for cleaning, leaving many scratches on the aluminum surface. And the scratched surface starts to get dirty much faster. The last layer - a nakryvka is applied on the practically dried out primed surface.

Removing beacons

Most builders usually do not remove landmarks at all. All this does not affect the issue of technical feasibility. Self-made approximate slats are not removed for several reasons:

- To perform plastering on beacons is quite fast. Trying to finish faster, workers simply ignore the need to eliminate beacons.

- Lighthouses are easy to remove, it will be more difficult to fill in the remaining grooves. Not every fan will be able to align the walls and not leave a trace.

Non-galvanized and cheap beacons should definitely be removed. Over time, the selected beacons for work begin to rust inside the walls, and this leads to the manifestation of brown spots on the surface.

Remove the lighthouses need, with almost complete drying of the plaster layer. To remove the beacons, you need to find their upper part, pry the profile with any convenient tool, use the pliers to break the profile down while tilting it. The work should be carried out in separate fragments of 25 cm. It is better not to break out the entire profile in order not to get more destruction.

Lighthouses made of wood must be removed immediately and without fail. And here the whole thing is in contrast to building materials. Plaster with wood react to existing environmental conditions in different ways, respectively, and they also “breathe” in different ways. The wooden lighthouse is mobile, so over time it will come off, and a crack will appear in the area of contact. All this will affect the thermal characteristics of the whole structure and the aesthetics of its appearance.

For information on how to install beacons and use the rule for plaster, see the following video.