Venetian plaster: its features and scope

In the modern market, Venetian plaster is becoming more and more in demand. Designers distinguish it for the possibility of creating an interior in the antique style. This article will consider the features and scope of this facing material.

Special features

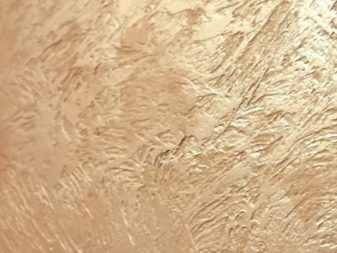

The main feature of Venetian plaster - texture, reminiscent of a marble surface. To get this effect, stone flour is used as a base. Dust consisting of granite, quartz, marble, or other valuable species forms the basis of the facing material.Next, add a binder material - synthetic fillers. Earlier, a mixture of lime and water was added to the composition, but this composition is obsolete.

Natural dyes are replaced with artificial pigments that do not possess toxic properties. Acrylic resins and synthetic polymers set the color of the future coating. Venetian plaster turns smooth, if it consists of small particles. The surface structure can be changed by reducing or increasing the size of the constituent parts. Together with the raw material, the masters advise to acquire the material to create a protective coating - beeswax or its analogues.

The composition of the mixture provides its mechanical properties that distinguish this coating among other facing materials. This mixture is quite viscous and plastic, which allows working with it not only to masters, but also to beginners. Color pigments have sufficient brightness, so the material can be laid no more than two layers.

Due to the complex structure, three types of surface can be obtained: a relief, a smooth coating, or a complex artistic structure.

Mixtures of plaster differ not only in names and color. Manufacturers emit several varieties of this material, which differ in the homogeneity of the composition. The quality of the future surface is directly related to the density and adhesion of the original product. The mixture with increased adhesiveness will provide a better coverage.

Plaster without dye transparent, coloring pigment is added to it before use. The most popular finish is a marble imitation coating. Designers like to use transparent material to get a glossy surface. However, such a coating requires careful preparation of the rough surface. Finishing is applied both on a wooden surface, and on a bricklaying.

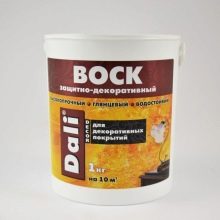

Depending on the technology of waxing plaster will turn out matte or glossy. If the layer of plaster is previously smoothed with a special device before applying the wax coating, then the future surface will shine. Matt effect is achieved by laying a thin layer of wax without pre-treatment of plaster.

Masters advise to choose fine plaster to obtain a reflective surface.

Advantages and disadvantages

Venetian plaster has a number of strengths and weaknesses.

Among the advantages of the wizard are the following:

- Environmental friendliness. Despite the fact that the composition of the Venetian plaster includes artificial polymers, it is not toxic. The covering can be used for facing of a nursery or a drawing room. The material does not adversely affect the body, so contact with it is absolutely safe.

- Moisture resistance. Thanks to the wax-based topcoat, the plaster is reliably protected from contact with water. The coating does not absorb moisture and does not collapse, so it can be used for cladding rooms with high humidity.

- Impact resistance. The surface is resistant to deformation, able to withstand external physical impact and sudden temperature changes. The service life of the plaster reaches 15 years. The strength of the surface increases when interacting with a mixture of carbon: a protective film is formed on the surface.

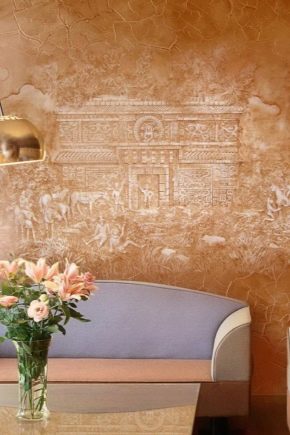

- Color spectrum. The material can be of any color and different texture - it depends on the design ideas and technology of installation. To obtain the desired saturation or effect, you must add the appropriate dye.The effect of antiquity can be achieved by adding about two millimeters in diameter marble granules to the mixture. Plaster also allows you to create an art painting, but this work requires appropriate skills and accuracy.

- Ease of dismantling. Partial repair or complete replacement of the coating is easy to implement. Due to the peculiarity of the appearance, the seams of the old and new coatings are not striking. The texture of the plaster allows repeated replacement of the laid coating.

In addition to the obvious advantages, Venetian plaster has several drawbacks.

They must be considered when choosing this coverage:

- Great expenditure of physical strength and time. High-quality laying of this facing material requires laborious and long work. The draft surface must be leveled, and the mixture must be laid strictly according to the technology. The smoother the texture is to be obtained, the neater the composition should be. Failure to comply with the rules will lead to the formation of stains and stains.

- High price. High-quality material contains natural rock, so it is not cheap.Facing cheap analogs looks too unnatural. In addition, the operational properties of the surface depend on the product quality.

Masters recommend not to save on raw materials and devices for laying in order to get the perfect coverage with a long service life.

Kinds

The most popular plaster is "Veneto". A characteristic feature of this type of coating is the effect of ground marble without gloss. Matt decorative surface suitable for facing any premises. The advantage of this plaster is its low cost and availability. The coating does not require special operating conditions, so it is advantageous to purchase it in families with children or pets.

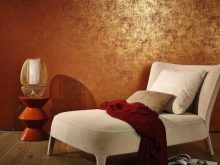

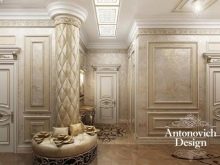

Trevignano - glossy plaster. The material creates a visual effect of interior lighting, creating a mirror effect on the walls. When laying the layers are half transparent, which allows you to overlay each other several shades. Such plaster will be an excellent solution for creating an interior in a classic style. The covering perfectly harmonizes with the frescoes.

If you want to get the effect of rough marble designersrecommend to buy plaster Marbello. Textured surface under the rays of light gives an unusual play of colors. The covering reminds a velvet with glossy impregnations or streaks.

Masters recommend using such plaster to decorate rooms with high humidity, because it is the most moisture resistant among analogues.

Materials with a matte surface are more popular in the market because they require less maintenance. "Ensausto" - semi-matt coating designed for those who are afraid of the appearance of stains on mirror surfaces, but who want to preserve shine. Reflective patches make plaster look like granite.

Acrylic plaster is made on the basis of acrylic latex. This coating is much easier to apply and quite firmly in application. The advantage of acrylic is that the surface can be made very bright. The water base allows you to tint the plaster in a variety of colors of any intensity. This coating is no less environmentally friendly than the lime equivalent.

Craquelure - decorative plaster with the effect of cracking. The grid of cracks is obtained by applying the solution, taking into account the special technology. Top plaster must be coated with water-based paint to protect the surface from moisture. Cracks are obtained when blowing the composition with a hair dryer and subsequent contact with air. It is possible to emphasize cracks with the help of final waxing.

Based on the technique of applying plaster, there are the following types of coating:

- Classic. Traditional multi-layered material, which includes marble chips, is great for beginners. Designed for decoration of large surfaces of walls or ceilings.

- Marble coating requires careful work on the imitation of natural material. High-quality detailing and accuracy in putting plaster on a draft surface is highly appreciated. This technology is used for the decoration of individual elements of the interior.

- Textured plaster is used not only to create the effect of a stone material, but also to imitate a wooden coating. Skilled craftsmen are able to recreate the skin from such a lining. Work with this type of material is best left to the master.

- Pearlescent coating is obtained by adding special particles to the raw material mixture. The blotches reflect the light, creating the appropriate shine. Such material is used to decorate some elements or sections of walls.

Styles

Venetian plaster is used to create interiors in various styles. It will be a worthy background space. It is important to take into account that the coating will truly manifest itself only in conditions of sufficient illumination, so a Venetian should not be used in dark apartments. The coating was widely used to create a classic interior, premises in the Empire style and baroque.

Baroque interiors are made with particular pomp. Use plaster with imitation of a noble stone, but not monophonic. It is important to choose a strong and durable coating that can withstand long loads.

The main distinctive feature of the Baroque is the abundance of stucco and monumental painting. Murals and three-dimensional patterns are mounted to the walls, so the plaster should not peel off.

When creating an interior in the Empire style, designers advise to avoid coarse stonework.The surface of the walls should be absolutely smooth with a slight sheen. An abundance of mirrors is welcomed, so plaster is better to choose matte. As in the Baroque, the Empire style can not be imagined without stucco on the walls, so the wall covering must have the appropriate properties.

Classical finishing of the room means the absence of unnecessary details. The walls are finished with plaster with patterns. Installation of such a coating requires a lot of time and appropriate skills. Patterns can be replaced with a monochromatic surface with an imitation of natural stone. Plaster should have a natural base and look natural. The advantage should be given to coatings of light colors: beige or dairy.

Design

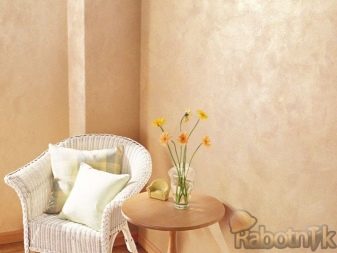

Geographically Venetian plaster can be placed anywhere, but with some requirements. The most optimal room for decoration with this type of facing material is a living room. The walls of this room do not experience excessive loads and are not amenable to excessive moisture, so there are no special requirements for plaster. Also, when designing a living room, it is rare to introduce any stylistic limitations, therefore the color saturation and the texture of the material are chosen at the request of the household.

For large-sized premises perfect "Venetian" bright color. It is important to remember that the room should be sufficiently lit, even in the daytime. In small rooms it is best to use light shades. The mirror surface will reflect light well, which will help to visually expand the space. But do not overdo it with glare surfaces, give preference to matte plaster with glittering inclusions.

Designers are advised not to get involved in the decor of the living room: a bright finish quickly bothers, and a long stay in a room with bright walls can cause a feeling of fatigue.

The application of this coating requires serious efforts and time-consuming, which deprives customers of the possibility of frequent interior renovation. The most advantageous solution is the coating of soft colors and imitation of a natural material: marble, granite or wood.

Masters recommend to pay attention to the installation of a stretch ceiling with veneer plaster lining. This design technique is quite new, so I did not have time to gain great popularity. It is worth noting the sophistication of this approach: the living room with a stretch ceiling, stylized as an expensive stone material, looks luxurious.Nevertheless, such a move is suitable only for rooms with a height of three meters or more. Small rooms with suspended ceilings seem flattened and uncomfortable.

Many are in no hurry to use the "Venetian" for facing the kitchen. Designers advise not to follow stereotypes about the inexpediency of using this material. High-quality plaster has all the necessary properties for operation, therefore it is suitable for finishing the kitchen room. It is only important to take into account some of the conditions imposed by the coating.

The plaster should be resistant to odors and not absorb them. The moisture resistance of the coating also plays an important role: the material must withstand short contact with water and wet cleaning of the room. During operation, the shade of the coating should not fade, and the surface covered with cracks. Also, the plaster must withstand sudden changes in temperature without visible consequences. To ensure all these properties, manufacturers add special components to the dry mix.

Despite the resistance of the coating to the effects of water, the masters do not advise the use of plaster in the area of the sink and plate. Preference should be given to wall tiles.Due to its complex texture, it is quite difficult to wash plaster from grease and dirt. The implementation of permanent restoration is unprofitable.

It must be remembered that this coating is perfectly combined with other types of materials, so it allows you to create complex images.

When facing with plaster bathroom preference should be given a uniform glossy finish. The marble surface will decorate the room in a classic style, and wet silk will create a beautiful iridescent coating. The surface of a complex structure can accumulate moisture, so there is a risk of mold and fungus. It is also useful to apply an additional layer of enamel, which increases the moisture resistance of the coating. The protective layer will greatly simplify the care of the surface.

Do not use the relief in the decor of a small room. But a smooth luminous surface can visually enlarge a small room.

Designers advise to give preference to white plaster when finishing the bathroom and bathroom.

The decor of the corridor with Venetian plaster will revive the apartment. The coating goes well with porcelain stoneware,therefore, they can cover the entrance area. To avoid rapid contamination of this area, it is preferable to use materials from a dark palette. An interesting combination of plaster with clinker tiles.

Colors

This coating has a wide color palette and many shades that allow you to bring to life virtually any design decision. Since the coloring pigments are added to the composition in the process of kneading the mass, the intensity of the color of the future coating depends on the wishes of the customer. Plaster without impurities - white and translucent. But such a material requires careful treatment of the base surface, so it is more convenient to paint the plaster.

"Venetian" well imitates the surface of noble stones natural origin, so she often ask light colors with a predominance of some pigments. Gray, green or yellow-brown plaster is widely used for facing the walls of the living room. Light yellow shades help to create an atmosphere of comfort and harmony.

For lovers of extravagant interiors and complex solutions, there is a black veneer.But such coverage is recommended to use only in spacious rooms. A very interesting solution would be to use a black finish with light transitions or divorces. Golden grid of cracks will make the interior truly unique.

To enhance the effect, designers advise to add a gold covering with decor from appropriate materials: candlesticks and gilded frames will make the room luxurious.

Tri-color cladding is not used as often due to the increased complexity of the application. However, you should not avoid the design of walls with modulations and difficult transition. This decoration is suitable for the design of a bedroom or a nursery.

It is important to remember that colors should be in harmony and not interrupt each other. You can complete the image of a bright room with the help of bright textiles or furniture elements.

Despite the abundance of colors and textures of Venetian plaster, the sales leaders are still natural colors and stylization of natural material. Eco-style is gaining increasing popularity: designers use decorative plaster even for the decoration of rooms in Scandinavian motifs.Mixes of neutral colors become real favorites in the market.

Which one to choose?

The operational properties of the coating may differ slightly depending on the area of its application. For facing surfaces in a room with high humidity it is necessary to pay special attention to the final coating: wax and enamel.

For use in the kitchen, the coating must have a high vapor permeability. The best solution would be to purchase material with high anti-fungal properties.

For finishing the walls in the corridor and the hallway, preference should be given to samples of increased strength. The entrance area of the room experiences constant temperature fluctuations, which increases its wear. It is necessary to select a material that is resistant to critical heating and cooling of the surface. Modern manufacturers create a "Venetian" acrylic-based: this coating has greater strength, but unnatural appearance.

Italy is the leader among material suppliers. Companies in this country create a classic coating, stylized as antique marble. The material is easy to apply, therefore it is suitable for use by both professional craftsmen and beginners. It is important to find material that does not require specific care.Pay attention to the quality of the final coating.

When buying, you should pay attention to the brand and serial number of products. It is not recommended to purchase plaster from different lots. The color of the finished product may vary significantly. To ensure uniformity of coverage, masters advise to mix the entire composition at once.

Kohler needs to select the same manufacturer as the dry mix: otherwise the components may not fit together.

Application area

Venetian plaster is used exclusively for interior decoration of walls and ceilings of residential and public buildings. Such a coating does not tolerate critical temperatures and natural precipitation, and therefore is not used for cladding facades. Also, plaster is used for partial decoration of some elements. For example, a fireplace or columns, decorated with "Venetian", look rich and able to decorate the interior in the Empire style.

Due to its resistance to moisture, the coating can also be used in the finishing of baths and saunas. Many use this coating even in the pool, but it is worth paying special attention to the selection of wax and enamel.On the quality and thickness of the layer will depend on the operational properties of the surface. Enamel can be applied in several layers to achieve the desired effect and quality of the coating.

The number of layers of "Venetian" can reach ten - it all depends on the design decision and the requirements for the future surface. You can apply layers that mimic travertine or onyx. You can also use plaster for art painting. For a long time, this technique of creating a visual effect has been used on the ceiling. However, you should not put too much plaster on the ceiling plates - they are slightly more difficult to dismantle than wall covering.

Tips for use and care

Before direct application of Venetian plaster should carefully prepare a rough surface. The material is applied to almost any surface, except metal and untreated wood. When applying plaster on such a surface, it can crack and quickly crumble. For such places, only an acrylic solution with a high concentration of gluing pigments is suitable.

The ideal base for plaster - brickwork, concrete blocks or plasterboard surface. Surfaces precoated with oil paint are also suitable - their rough base ensures adhesion of the plaster layers. It is important to remember that surfaces must be durable. The draft cloth is cleaned from dust and other impurities. Chips or protrusions should be corrected with a small layer of putty and the subsequent leveling of the surface.

If the surface was previously painted, it is necessary to remove the outdated layer of paint. The seams between the plasterboard must be glued and cleaned to get rid of height differences. If it becomes necessary to lay the plaster on a weak surface, then it is customary to reinforce it with a metal grid so that deformation does not subsequently occur.

Next, the wall must be covered with a layer of putty and walk on it with sandpaper. It is forbidden to leave dust on the treated surface - it will reduce the adhesion of the layers of the future coating and lead to rapid destruction. Following impose a layer of deep penetration. The process of puttying and subsequent grinding should be repeated until the rough surface is perfectly flat.

It is important to observe the time intervals between laying layers - the surface must be completely dry. Otherwise, water between the layers will cause cracking.

The drying process depends on the humidity in the room and the air temperature. The more vapor in the air, the longer the drying process will be.

If the rough surface looks flat, and the drops do not exceed two millimeters, then you can begin the process of laying plaster. For the preparation of the future mixture using dry powder, which must be diluted with water in the desired proportions. The resulting mass should resemble sour cream in consistency and be homogeneous. Next, fall asleep color pigment. To make the material better mixed, the masters recommend using a construction mixer.

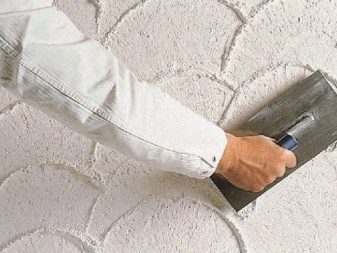

The first layer should consist of fine marble chips.Subsequent may contain large inclusions. Each layer dries from four to six hours, so the installation requires a lot of time. Lining layers are necessary for obtaining the planned pattern and also take time to dry. The advantage of plaster - the mass is easy to apply and spread without effort.Spatula is recommended to press to the surface at an angle of fifteen degrees.

In the process of mixing the material its temperature should reach 11 degrees: under such conditions, the components dissolve well. It is necessary to withstand about ten minutes to allow the mass to adhere. After this time, the mixing process can be resumed.

A dry mixture of plaster can be obtained independently, knowing the proportions and recipes. But it is better to buy ready-made, because all the properties of the coating depend on its choice.

Properly laid coating does not require special care: the surface can occasionally be wiped with a damp cloth. It is important to remember that the coating does not tolerate interaction with solvents. Therefore, you need to purchase care products carefully.

To extend the life of the plaster, it can be enameled once every several years.

Tools and components

The following components are necessary for the creation of the coating:

- Primer. This material is used to pretreat the surface. The technology of applying the primer has been described previously. It is important to remember that quartz filler must be part of the soil.

- Water intended for setting the dry mixture and obtaining the mass of plaster. Water must be poured into the mineral powder gradually so that the mixture does not turn out to be too liquid.

- Kohler. Special coloring additives designed to obtain coverage required shade. Color pigments are added after mixing the main mixture. The first layer of plaster is applied clean, without the addition of coloring pigment.

- Sanding paper. It is necessary to stock up with sandpaper of varying degrees of grain. First, large particles pass over the surface, and the final polishing is carried out using fine-grained paper.

- Wax. The final coating can be liquid or in the form of a paste. The wax is used to protect the coating from water and steam. Also, this tool gives the coating additional strength and protects against contamination.

- Enamel. This material is placed on top of the wax coating in the event that the plaster requires additional protection from exposure to water.

To work directly with the already prepared plaster requires special tools. For applying to the wall primer need a spatula or roller.The choice of a device depends on the thickness of the mass and its viscosity. A spatula is applied to a thicker mass, evenly distributing the layer from the edges of the wall to the middle with smooth movements. Roller is more suitable for creating a smooth surface of a more mobile plaster.

Trowel - small steel shovelwhich helps spread the mass over the surface. Unlike a trowel, this tool is suitable for working on small parts or hard to reach places. To work with Venetian plaster masters advise to buy a trowel with rounded edges to avoid rough marks on the resulting surface. Often combined trowel in working with a spatula, less often used as the main tool for coating.

To apply wax, purchase a special rubber spatula. Unlike a steel sample, rubber spreads wax more easily across the surface and can create a thin coating. Also for work with wax get a wool mitten.

Gladilka or rule will allow to obtain a truly flat surface. These tools are used to produce a smooth coating with the least embossing. The roller is also able to create a flat surface, but working with it will require much more time.

Do not forget about dry rags for wiping surfaces and tools at any stage of work. It is important to remember that even the smallest particles can affect the quality of the future surface and adversely affect its performance properties. A stepladder is necessary if you are to cover the wall or ceiling. The device must be stable, its serviceability must be checked before operation.

To get a glossy surface, trowels will not be enough. Masters use a special machine for polishing wax. The set should include a special nozzle, smoothing the coating without causing harm to the surface.

Application details

To obtain the necessary visual effect, plaster should be applied in a specific way. An improperly chosen technique can result in a visual effect that is different from the one intended. You can experiment with the alternation of color and transparent layers, and you can follow the proven methods of applying Venetian plaster on a rough surface. Consider several technologies for the application of facing material.

To obtain a scaly structure put a layer of plaster from three to five millimeters. The size of the future scales is directly proportional to the thickness of the putty. To imitate the scales with a spatula hold vertical stripes.

The device is chosen in the size of ten centimeters: the smaller the spatula, the more accurate the scales will look. But it all depends more on the skills of the master.

A completely dried coating on top is usually covered with a layer of paint. You can paint the shiny paint scales themselves or the surface between them. It is important to remember that the paint will not fall equally easily on every plaster. It is necessary to get acquainted with the composition of the coating and purchase the one that is intended for the subsequent coating with paint.

To obtain a cave-like surface, a layer of plaster is applied in broad strokes on the prepared surface. In order to get small neat bumps without harming the coating, the masters advise using a sponge to create an unusual semi-finished texture.

Another interesting surface treatment method is to use a wrap film that needs to be removed from the surface at the end of the day.

Any print or print will turn out on a soft plaster. Upon receipt of the filler of the desired softness, it is important to remember about the preservation of the density of the material. Too liquid plaster will not be able to stay on the rough surface and will drain from it.

Rock texture is great for decorating the premises in a classic style. The wall is evenly covered with a layer of putty about three millimeters thick. As the layer increases, the pattern appears stronger. This technique is also used in the decoration of window sills and fireplace.

Because of the ease of application, this method is the most popular and suitable for laying even beginners.

After mounting the layer of plaster and before it is fully dried, the surface is described with a metal trowel. The pattern imitating the rocky surface is applied with a slight pressure. The lines can be straight, but the strokes look more interesting under a slight slope. Subsequent surface painting will visually increase the resulting “cracks”, completing the image.

Designers advise to simplify the process of applying the pattern on the wet plaster, wrapping the roller with the appropriate textured material.The resulting device is able to immediately cover a large surface, significantly reducing the time spent on achieving the desired visual effect. Experiment with the surface: wrap the roller with a mesh or non-woven textured wallpaper.

It is possible to coat the surface with wax only a week after the last layer of plaster has been applied. Wax, you can choose both natural and its synthetic counterpart. On the modern market, you can buy an absolutely harmless coating made of artificial materials, which are not inferior in properties to natural components. Some types of artificial wax are able to withstand even the effects of strong solvents.

The composition of the wax mixture may include additional dyes. By applying wax on the final surface, it can be given a gold or pearl luster. The wax should be applied in a thin layer, trying to avoid dripping or peeling.

If the layer of putty has a complex convex texture, the wax is applied with neat circular movements. The wax is quite fluid, therefore it is able to penetrate even into small cracks, protecting the coating from moisture and giving it a luminous shine.

Further, the surface can be smoothed with a grinding machine, if there is a desire to obtain an ideal mirror surface. It must be remembered that on such a coating, as on tiled masonry, streaks will be visible. Therefore, the resulting surface will require more careful handling and thorough cleaning than its raw counterpart.

If there is no grinding machine, then you can even the coating with a soft cloth.

Practical tips and tricks

In cases where the result does not match expectations and the coating requires disassembly, the surface should not be allowed to dry. It is necessary to immediately impose the next layer to obtain the intended texture. Otherwise, it is necessary to partially remove the layers and carry out operations on the preparation and leveling of the surface.

If the surface is partially deformed or damaged, the defective layer can be carefully removed. Next, some plaster is applied to the damage and a new layer is leveled. After complete drying, the surface can be cleaned with fine-grained sandpaper. After stripping, the affected area is coated with wax and left to dry with the entire surface.

Glossy surface allows you to apply additional decorating layers. Thanks to the transparent base, you can create a beautiful overflow of color. It is important to apply a thin layer of color coating. The layers should partially overlap each other, and subsequently level off. This will help create a smooth color transition without disturbing the coating uniformity.

The thickness of the layers can be changed by pressing the spatula.

Masters are advised to click on the fixture during the initial laying of the layer, and to finish the application with a light touch. This technology will provide an ideal surface.

Experts recommend that you always keep a clean rag and water containers at hand. After use, all fixtures should be cleaned immediately, and soak spatulas and rollers in clean water. In the process of work it is important to monitor and timely remove the pollution from the tools. Violation of this rule entails a violation of plaster laying technology.

You should not stick to one scheme of laying material and be afraid to make mistakes. Much more interesting is the coating with large gaps and an unsystematic pattern.Venetian plaster is able to completely recreate the natural natural coating. But after all in the nature the accurate consecutive pattern practically does not meet. Therefore, do not be afraid to experiment with coverage.

It is important to constantly monitor the cleanliness of the rough surface and the applied layers. Due to the increased transparency of the coating, any contamination will be emitted. Such contaminants must be removed immediately. Also, dust grains degrade the adhesion of the layers, which can lead to delamination of the coating during operation. Small debris can cause a grid of surface cracks.

Manufacturers and reviews

If the question of using Venetian plaster as a facing material is still controversial, then you should read the real customer reviews that already use this material in repair.

Buyers note that decorativeVGT cover on the basis of natural marble chips differs affordable price and a wide color palette. Among the shortcomings of this material, customers identify insufficient adhesion to the wall.The manufacturer offers this coating of any grain, but customers recommend making a choice in favor of coarse-grained samples. This coating is characterized by saturation and beautiful texture.

Also, decorative plaster with large patches is easy to use and even suitable for beginners to repair.

Venetian plaster can be purchased from domestic manufacturers. Buyers are satisfied with the work with the material produced in Russia. Coverage has a low price, so it is perfect for young families with a limited budget. Customers note that even for a small amount you can buy quality material that looks like natural stone.

Russian companies produce coatings that are conveniently applied in several layers. Buyers note the smooth texture of the applied coating, high-quality structure and a wide color palette. The material can be applied even in the zone of high humidity, it retains its properties throughout its entire service life and does not require special care.

Beautiful examples in the interior

To choose the appropriate style and method of applying Venetian plaster,need to familiarize yourself with the works of other masters. Such an analysis will allow you to find the best texture and inspire experimentation. Below are some of the design solutions for interior decoration using decorative plaster.

The light antique coating is perfectly combined with wooden elements of the interior. Designers preferred ivory-colored plaster to fill the room with light and visually enlarge the space. This coating serves as an excellent background for placing massive paintings in wooden frames and mirrors. The finished surface is painted with broad strokes: this effect is also used in the decoration of wooden furniture.

When applying the material, the wax surface is not leveled in order to avoid the appearance of specular gloss. Light walls and the corresponding elements of furniture visually lengthen the room. The massive chandelier also looks appropriate: thanks to the high ceiling, its complex structure looks organic.

Venetian plaster is used as a facing material in the design of the kitchen. An important nuance - plaster is not applied to the surface, constantly in contact with water.A wall covered with saturated green material creates a certain depth of space. This color is in perfect harmony with kitchen utensils and built-in appliances - the room looks modern and stylish.

Pictures and basics of the corresponding tone maintain the color of the walls and complete the image of the room. Solar and summer kitchen pleases the owners at any time of the year, and rich colors do not cause indisposition. Overhead, reflected from the glossy surface of the wall, fills the room with air and shine.

Contrary to stereotypes, Venetian plaster can be used not only to create an interior in the classics or ampire. Designers use this cover in the design of the room in a modern fashionable loft style. The facing covering imitating a rough stonework can be combined perfectly with the metal elements of this direction.

Venetian coating under the red brick serves as a color accent in the design of a spacious kitchen. The illusion of an expensive stone is in harmony with the wooden ceiling and the metal floor. The room looks cold and strict, as the loft requires. Due to the wide color palette, this coating is best suited formaintain color composition.

For the decoration of the walls in the bathroom and the bathroom, a special waterproof plaster is used. This coating undergoes additional enamel processing and can last for many years without the formation of fungus and corrosion. Designers have created an unusually refined image of a bathroom using Venetian plaster with a golden sheen. Due to its multi-layer structure, the coating looks deep and complex.

The matte surface is great for mounting a massive mirror in a decorated gold frame. The light walls, marbled, combined with furniture made of noble wood. The image is completed with small gilded details and elements of stucco around the perimeter of the room. The surface of the plaster does not shine, because there are enough reflective parts in the room.

Coarse-grained Venetian plaster is used to design corridors and loggias. Light coating in harmony with the wicker surfaces of furniture, creating an atmosphere of comfort and coziness. The floor, tiled, repeats the texture of the walls, creating a single bright space.Masonry does not look coarse, on the contrary, in the elements of the hallway there is a certain softness and smoothness of forms.

Wooden windows contrast with light-colored surfaces, becoming the emotional center of the room. When light pours through the glass, it reflects off the cream surfaces, filling the room with warmth. Color accents are placed with the help of colored decorative elements - pillows, bags and textiles.

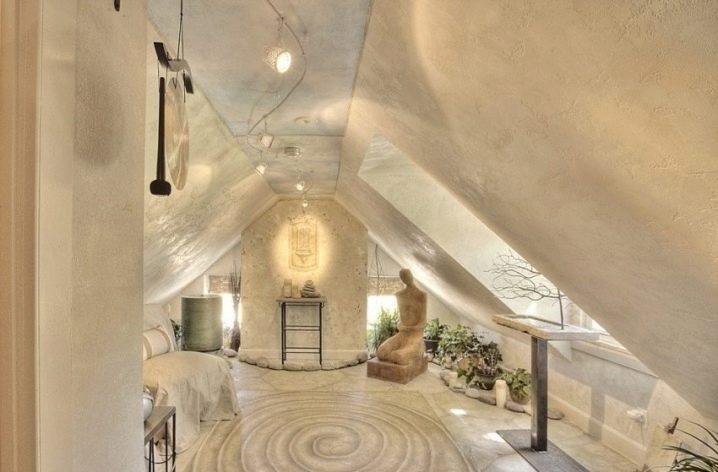

Thanks to decorative plaster, you can make complex patterns on the ceiling and walls of the attic. Usually a small room is visually multiplied by the use of a coating of light colors and soft forms. Overhead light reflects from the complex shape of the ceiling, creating the illusion of a “cave”.

The material for the decor is chosen appropriate: the coating looks like real rocks on the seashore. To complete the interior, the floors are carpeted with a spiral pattern. A stone statue near the wall will come to the image of the interior of a note of antiquity.

You can learn more about Venetian plaster from the video.