Plaster walls: features and subtleties of the process

Plaster is a versatile and very popular material. It is used in many finishing works and is an indispensable part in the repair of any home. Both an experienced and a home master can easily cope with it. Today we take a closer look at the features and subtleties of the process of applying plaster.

What it is?

Almost all repairs, with the exception of communications, begin with plaster. It is a mixture, which contains components such as sand, cement, lime and a certain amount of water. Plaster is needed for rough finishing, it can also act as a suitable base for various decorative elements. She can finish a variety of surfaces - the main thing is to choose the right composition and knead it correctly.

Special features

Plaster is rightfully recognized as one of the most popular finishing materials. It is used for different purposes, repair work in a dwelling is extremely rare without it. Such a composition can act as a base for any finish, or as a finished finish of a surface. It is worth noting that this finish also has stylistic properties, for example, the use of light plaster on the walls can visually expand the room and make it lighter.

Currently, there are so many varieties of quality plaster, it is produced by many brands. Even the most demanding consumer will be able to find the perfect option. In the shops you can find not only interior, but also facade plaster. Most mixtures are characterized by excellent performance and strength properties. Of course, a lot depends on how you apply the plaster: if the work was done incorrectly, the mixture will not last for a long time.

The main feature of the material is its ability to conceal various defects and irregularities of the walls. Because of this, it is very often used in the preparatory work before applying the main finishing material, for example, pasting wallpaper or painting. In addition, the plaster can boast of its unpretentiousness in the base material - it can be applied on a variety of surfaces: concrete, brick, stone, wood, drywall and any other materials. This feature suggests that the plaster is permissible to use in a variety of dwellings: from a normal city apartment to a country house or a country villa.

High-quality plaster does not absorb foreign odors, which are often not the most pleasant. Thanks to this feature, this mixture can be used in the design of balconies and loggias, as well as dining rooms and kitchens.

Many consumers opt for plaster, as it has sound-proofing characteristics. Of course, its layer cannot be so dense as to absorb all the extraneous noise, but to a certain extent it protects the space from unnecessary sounds. Given the above features, home interior designers in their developments refer to this decorative finishing material.As mentioned earlier, it can be used to fundamentally change the image of a room and even “transform” its structure.

Plastering is fairly simple and affordable., it does not need to have special knowledge and extensive experience in repair work. Before applying it does not need complex preparation of the base, and sometimes it is not required at all.

Most modern plasters are quite durable and reliable. They are not afraid of temperature extremes and harsh climatic conditions. Of course, a low-quality mixture of doubtful production cannot boast of such properties, therefore, experts strongly recommend to apply only to high-quality branded products.

Plaster has breathable characteristics. Due to this peculiarity, the coatings finished with this mixture become “breathing”, therefore, no fungus or mold appear on them. The material forms an environmentally friendly and completely safe coating, which is practical and resistant to mechanical damage. Because of this, the composition can be chosen to design a variety of rooms, including in the children's room.It does not emit harmful substances even in high temperature conditions, therefore the health of small households will not be endangered.

Another feature of the plaster is its high plasticity. This property makes the solution quite pliable and easy to use. Using plaster, you can finish any complex structures, as well as create original drawings, patterns and other decorative elements.

Types of mixtures

Many consumers believe that the plaster is a single mixture and does not have any varieties - this opinion is wrong. In fact, in the shops of building and finishing materials you can meet many different types of plaster, with its own distinctive properties and components in the composition. Consider them in more detail.

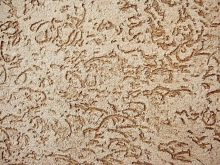

The textured mixture differs from other solutions in its structure: it is coarse and highly viscous. Fillers in the composition of such mixtures are flax fibers, wood, mica and special crumb (of mineral origin). This plaster can be purchased only for the walls of brick, concrete or wood.In addition, it is suitable for both internal and external works. The facades of buildings decorated with such plaster look quite attractive.

With the help of the material, you can hide many of the shortcomings of the walls., as it has special particles in its composition. It is permissible to safely use it for leveling floors, but far from all the mixtures cope with this task. For applying textured plaster, the bases do not need to be prepared for a long time and are diligently prepared - they are sufficiently dried and cleaned of excess debris and old finishing coatings if they move away from the walls. This is followed by the stage of applying a special adhesive composition, so that the plaster “mates” properly with the overlap.

Textured plaster has a large number of positive characteristics:

- It is moisture resistant and does not suffer from contact with water.

- Forms a breathable coating. Thanks to this property, the walls in the room will not be subject to the formation of fungus or mold.

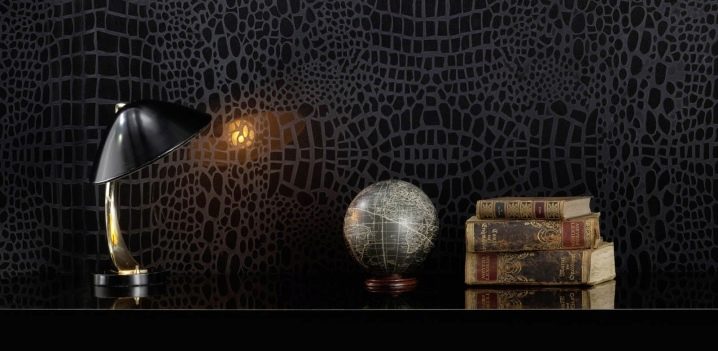

- Able to repeat a variety of surfaces. For example, it can be a spectacular imitation of masonry, natural leather, beautiful wood with its natural structure or fabric.

- Apply this mixture without the use of special tools.In addition, it is not necessary to involve specialists for its application, since even an inexperienced user will be able to cope with such work.

Among all types of materials, this is one of the most popular, as it has a relatively affordable price.

There are several subtypes of textured plaster:

- The Lamb This mixture consists of stone grains with different sizes. As a rule, it is applied to bases of mineral origin. As a result of their use, the surfaces are grainy.

- Fur coat She creates a slightly rough and fuzzy texture on the walls. The main component of this mixture is concrete.

- Bark beetle This kind of plaster is composite. It has a stone filler. After it is applied, the surface of the base becomes furrowed and resembles eaten wood.

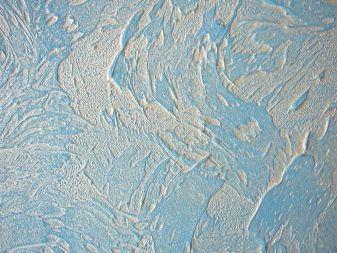

Another type of plaster, structural, has a thin-layer composition, it is created on an acrylic or silicate base. In the composition there is marble crumb or particles of quartz. As for appearance, it is grainy and non-uniform.Structural plaster is used for various purposes: for the decoration of partitions inside buildings, and for the decoration of facades of various structures.

There are several types of mixes:

- Fine-grained. This mixture after drying forms an almost smooth layer.

- Medium grained. This solution forms a slightly rough and embossed surface on the wall.

The structural mixture has good adhesion with most mineral surfaces. In addition, it can be used in the finishing of drywall or laminated chipboard.

The advantages of this plaster are:

- High breathability.

- Resistant to moisture.

- Portability of temperature differences.

These compositions are produced in packs of 9, 18, 50 kg. The stores supply ready-made blends to which no coloring components are added. It is necessary to apply such plaster with use of a trowel on a completely dry and cleaned surface of the base. Experts strongly do not recommend contact with this finishing material in rooms with high levels of humidity. If you are engaged in the design of the facade, then you should not do this in the rain and when the air temperature is less than 7 degrees.It should be noted that structural plaster is often used for finishing fences and gates.

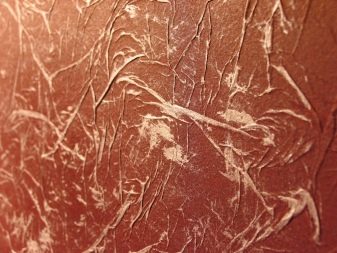

Another type of plaster - Venetian - is one of the most luxurious. After transfer to the base, it forms a coating resembling beautiful marble or rich onyx. However, it is necessary to take into account the fact that working with such finishing materials requires sufficient experience and a certain skill from the master. Otherwise, the surface of the grounds will not so spectacular. Such plaster is quite expensive, so consumers do not often turn to it. However, the effect that it creates indoors justifies the high price. Because of the noble appearance, such a plaster is often used in the design of elaborate interiors in styles such as Baroque, Rococo, Empire, classical, neoclassical or art deco.

Such mixtures are applied using special thin spatulas and extremely thin strokes. According to experts, the Venetian plaster should be applied in 5-6 layers, but each layer should completely dry out.

It is possible to apply the Venetian mix in the different ways as it happens:

- Matte.

- Glossy.

Both options look very impressive. The choice of the optimal solution depends on the style of the situation and the desires of the owners.

In addition, one or another color scheme is often added to the Venetian plaster. Venetian plaster can be used not only as a basic finishing material, but also as a base for another coating. For example, it can be a luxurious fresco, a complex and intricate panel or mosaic canvas. This kind of plaster can imitate not only expensive rocks, but also precious metals, since it contains a special pigment. With the help of such a finishing material, you can create the effect of a more spacious and free space indoors. It is achieved due to the refracted light.

Do not forget that this plaster is only suitable for decoration indoors. For exterior trim it is not necessary to apply. Venetian plaster is produced in packs of 8 kg and 16 kg. It must be applied to a dry and clean surface. In addition, it must be pre-aligned.

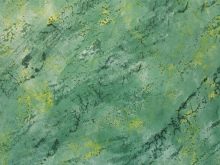

The so-called “colored” type of plaster is classified as specific and is made on the basis of acrylic and marble chips.

Such a finishing material has a number of features:

- It fits nicely on mineral bases.

- Differs in moisture resistance.

- It is quite hard.

- Available in a palette of 15 attractive shades.

- It can be applied in just one layer.

Before applying colored plaster, it is necessary to prepare the base by thoroughly cleaning and drying it. In order for ugly joints not to be visible on the surface of the floors, the mixture should be brought to a corner. Colored plaster can be used for both internal and external works.

There is a roller mixture that can be distinguished by an environmentally friendly and safe composition, it includes fillers of natural origin. After application, it forms on the basis of an interesting texture with small canal dimples. Roller plaster can be used for processing the facade, as well as for the registration of partitions inside residential and office premises. Tinting of such solutions or their surface staining is possible. Roller plaster should be applied with a special wide trowel.Then the mixture must be rubbed with a trowel in circular, vertical or cross movements.

It is worth noting latex-plastic, because with this mixture you can create a smooth surface on the walls, which has a light gloss. Especially attractive and expensive look coating, imitating stone or marble. Such a finishing material boasts wear resistance: it is not subject to the formation of ugly cracks. In addition, it is moisture resistant, which is why the surface, finished with latex plaster, can be washed if dirt appears on it. The material can be tinted at its discretion: it can be absolutely any shade, in order to give the mixture the effect of a stone structure, you need to mix the solution less carefully and scrupulously.

Latex plaster must be applied on a perfectly flat base surface. Slabs need to be pre-treated with a putty and a deep penetration primer to achieve the desired result.

If you want to find the original and unusual coating, then you should look in the shops for wet silk plaster.After hardening, these coatings look like fabric, which looks quite interesting. As part of such a mixture, there are special mother-of-pearl components that create spectacular play, and they imitate the surface of fine silk.

It is also possible to add any colors to such compositions, but initially they are available in the following colors:

- White

- Golden

- Pomegranate.

- Silver.

- Bronze.

Created coatings have high moisture resistance: they can be subjected to wet cleaning, without fear that the coating will lose the brightness of the color or will begin to crack. Quite often, this type of plaster is used in the decoration of the kitchen.

“Sea Breeze” is another decorative coating, which has an unsurpassed appearance, it has a translucent structure, which has an unobtrusive and barely noticeable tint of nacre. The composition of such a mixture is often filled with fine-grained sand.

The material can undergo klelering, but is initially manufactured in the following palettes:

- White.

- Red.

- Golden.

- Chameleon.

Experts recommend using the "sea breeze" exclusively for interior decorating.

For additional insulation of the room, you can use high-quality heat-shielding plaster.

In the composition there are special fillers that increase its effectiveness and enhance the quality:

- Foam glass.

- Styrofoam (in the form of granules).

- Foamed perlite.

- Vermiculite

The most popular are polystyrene foam and perlite mixtures; in the latter case, pearlite is present - a special component that is a mineral of volcanic origin. Heat-shielding plaster is fairly light, because in its composition there are small fillers. Thanks to this feature, the mixture can be used to create the most comfortable indoor microclimate. In some cases, the use of heat-shielding composition allows the owners to refuse additional insulating sheets of polystyrene or mineral wool.

Another popular type of plaster is an acoustic mixture. It is necessary to significantly reduce the noise level in the room.Particularly often, similar compositions are addressed in the decoration of large industrial premises, cinemas and sports halls, where extraneous sounds are common. Acoustic plaster is indispensable if architectural curvilinear forms are present in the room, it is also possible to refuse the use of suspended acoustic structures, if their installation is not possible. Consumers say that it is much nicer and more comfortable to be in a room with such decoration, especially if the floors are decorated with hard materials.

Waterproofing a kind of plaster, as a rule, is composed of special waterproof polymers. It is necessary for the preparation of special waterproofing layers in rooms or buildings with a high level of humidity. Acrylic, epoxy and polyurethane resins are used as a barrier fluid for such plaster. In order to make the mixture water-repellent more effective, the solution should be applied using a special cement gun (otherwise it is called a toncrete machine).

There is a sanitizing plaster, which is otherwise referred to as draining. It is ideal for finishing in rooms with high levels of humidity. With the help of such mixtures it is possible to carry out high-quality drainage of floors, without producing excessive mechanical effects. Such compositions have a porous structure, due to which the evaporation area increases markedly.

Silicate polymer plaster is usually produced in the form of a ready-made solution that does not need to be kneaded. This finishing material is absolutely safe and environmentally friendly. In addition, in the shops you can find silicate plasters of various colors. First of all, such mixtures are produced for facade finishing works, but experts say that they can also be used indoors. Silicate mortar will be interesting to look in the interior of the kitchen, loggia or balcony.

The advantages of such plaster include:

- The possibility of applying on concrete, plasterboard and limestone bases.

- Increased vapor permeability.

- Not susceptible to deformation.

- Resistance to rain.

- No unpleasant and pungent smell.

- Rich colors.

- Increased strength.

- Ease of application.

- Fireproof.

Apply this mixture should be very fast, an inexperienced master with such work can not cope. In addition, silicate plaster is necessary to cover the base, treated with a special primer. Serve such a mixture is not very long.

If you want to buy an environmentally friendly type of plaster, then you should consider option to buy clay mixture, which has many positive qualities:

- Clay plaster quickly absorbs moisture and give up moisture. Due to this quality, these coatings are very long.

- Low cost.

- Clay plaster perfectly protects the base from mechanical damage.

- This mixture is elastic, so it is easy to apply and hassle-free.

- Clay plaster is suitable for finishing inside and outside the home.

- Using a similar composition, it is possible to level significant differences on the surface of the walls.

As for the lack of clay solutions, these include:

- The lack of a clear formulation for the manufacture of mixtures. Specific proportions for the manufacture of such plaster does not exist, because of which each master makes it in his own way.

- The possibility of cracks. Drying the clay solution too quickly can cause it to crack.

- A very small number of experienced craftsmen. Today, clay plaster is rarely used, which is why few really experienced workers who are well acquainted with this material.

Which is better?

It is difficult to say which plaster is the best, since the choice of a suitable mixture depends on the room in which you are repairing. For example, for a cool room the best option would be a heat-shielding mixture, and in a high humidity area sanitizing and waterproofing solutions are ideal.

In drawing up a beautiful and stylish interior, you should choose one of the spectacular decorative mixtures. The most expensive and luxurious of them is Venetian plaster, it is she who is recognized as the best option when it comes to creating a pompous ensemble. The choice of the optimal decorative composition depends on the style and "mood" of the interior.

In order to avoid extraneous noise in the room, you should use a special sound insulation plaster.

Choosing the best option for finishing your home, you need to pay attention to its composition and performance. High-quality plaster should be vapor-permeable, waterproof and durable. Such coatings not only serve for many years, but also maintain an attractive appearance for a long time.

Application area

Different types of plaster are suitable for a wide range of works, for example:

- Most formulations can be used for interior decoration. Even silicate mixtures designed to finish the facade are allowed to be used in the design of the internal space of the dwelling.

- Decorative plaster, as a rule, is used for internal repair work.

- For facade works often choose not only silicate, but also structural, texture and roller mixtures.

- For the finishing of brick foundations it is recommended to use cement-based mixtures. The thickness of the applied layer should not exceed 3 cm.

- Concrete floors can be plastered, but first they should be treated with primer mixtures, which include quartz sand and flour. Cement plasters containing gypsum or gypsum-lime mortars are recommended for such bases.

- If the walls in the building are made of gas or foam blocks, then they are recommended to finish with a porous plaster of deep penetration.

- Such material as foam plastic can also be subjected to plaster treatment. To do this, use a universal facade mixture (if we are talking about the design of the facade) or mineral composition.

Universal facade plaster - a reliable and moisture-resistant mixture that is not afraid of harsh climatic conditions and temperature extremes. This composition is perfect for exterior decoration, it will last even longer and will look neater if you install a special reinforced mesh under it.

- Mineral mixtures are also often used for facade finishing works. The basis of such compositions is Portland cement of normal white color, as well as lime and various fillers. Such solutions are very strong and have high adhesion with many surfaces, including the above-mentioned foam.

- Modern acoustic mixtures with enhanced sound insulation characteristics are used in the decoration of noisy areas.This may be a concert hall, cinema and other similar spaces. Of course, in a normal residential apartment in a new building or in a private house, it can also be used.

- Latex mixtures can be applied to a wide variety of surfaces, but they should be prepared in advance - coated with a putty and special primer.

- Universal is a modern plaster plaster. It can be applied on dense mineral bases, foam concrete with a cellular structure, silicate bases (aerated concrete, brick), as well as heat insulators of synthetic origin, such as polystyrene or foam. When choosing such a mixture, it should be borne in mind that it does not tolerate certain atmospheric phenomena, since it is not waterproof and washable.

Colors

Plaster can have different colors, it depends on this indicator how the room in which the repair is made will look. The stores sell different formulations. As a rule, plasters are realized in finished form and all you have to do is add one or another pigment to them. However, it is necessary to act very carefully at this moment in order not to overdo it and not to make the shade too bright and coarse.

After the correct application of the painted mixture, the finishing work must be completed.having painted overlappings with a special paint and varnish composition. Here you can combine different shades, but if you do not want to experiment, you can choose the same color that was originally. You can also add a special colourant to the plaster to give the wall a suitable color. However, it should be borne in mind that in this case you will have to repaint the overlapping in order to make them look more lush and saturated.

Plaster can have absolutely any color, the most popular are pastel compositions:

- Blue

- Green.

- Pink

- Peach.

- Pale yellow.

- Turquoise.

If you want to decorate the interior with unusual shades, then you should turn to decorative compositions, such as "sea breeze" or "wet silk", as they may have golden, silver and bronze colors.

How to calculate the flow?

Before proceeding to the finishing works, it is necessary to calculate the consumption of plaster mix per 1 sq. M.

It can be calculated in this way:

- First you need to calculate the desired thickness of the layer.

- Further it is necessary to clear the basis.

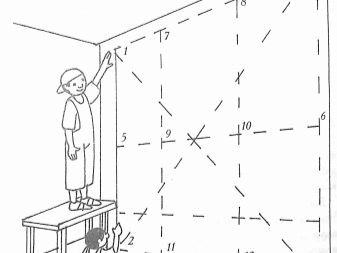

- After that, you need to hang the surface, putting beacons or special slats.

- At different sites need to find key points. Further, the basis deviation from a regular and even plane will be determined from them. The more points you select, the better the result will be.

- Now you should measure all deviations, add them and divide by the number of marked points.

To make this method of calculating material more understandable, it is worth giving a specific example:

- For example, you need to cover with a mortar a foundation with an area of 10 sq. M, bevelled at 50 mm (note that the maximum deviation may be 5 cm).

- In the case of hanging three points, we get the deviations - 1 cm, 3 cm, 5 cm.

- It is necessary to add the results - 1 + 3 + 5 = 9 cm.

- Now it is necessary to divide the resulting value by the number of hung points - 9: 3 = 3 cm.

- Based on the obtained results, we can conclude that for a neat and uniform base coating it will be necessary to transfer the middle layer, which is 3 cm.

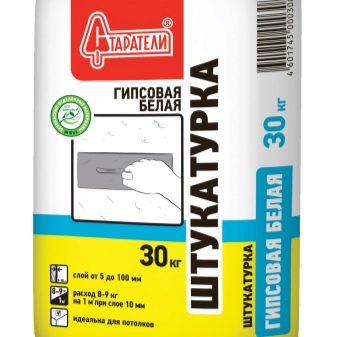

After determining the middle layer should be acquainted with the recommendations of the manufacturer on the issue of calculating the material consumption. As a rule, it is indicated per square meter, provided that a layer of 10 mm is applied. This information is on the packaging.In the case of high-quality plaster problems in this matter should not be.

For example, on a dry solution Knauf Rotband indicates that the design of one square meter of base with a layer of 10 mm will take 8.5 kg of plaster.

Based on these indicators, you can make a further calculation:

- We multiply the norm (in this case 8.5) by the average thickness, which we calculated before that - 8.5x3 = 25.5 kg.

- As a result, we obtained the consumption of Knauf Rotband solution for finishing one square meter of base.

Instruments

If you plan on your own to plaster the ceiling in the room, then You will need the following tools and additional mixes:

- Putty knife.

- Lighthouses

- Grater.

- Drill.

- Cellular calico with dimensions 1.5x1.2 mm, 2x2 mm, 5x5 mm, 10x10 mm.

- Trowel (trowel).

- Special metal trowel.

- Net capacity.

- Rollers, stamps. Such devices are much more convenient to apply the textured mixture.

- Paint. It will be needed if your plaster has a simple white color and is not painted.

- Water based varnish. He will need to fix the paint layer.

- Primer for painting.

Technology works

If you want the plastered surfaces to look aesthetically and carefully, then you should follow the appropriate application technology and certain stages of the finishing work.First, the base is prepared, then you can proceed to the marking of the floors and their primer. It will also be necessary to install beacons. Only after these stages can you cover the walls with plaster. The final stage will be the design of corner sections and platforms near the floor and ceiling.

How to make a mixture?

Before direct preparation of plaster it is necessary to take into account the basis on which it will go.

- Cement and lime options should be used for exterior decoration of buildings. They are also suitable for areas with high humidity.

- Lime and gypsum compositions can be used for decoration of wall and ceiling foundations in spaces with low humidity levels.

- Plaster mixes in which there is an environmentally friendly clay, ideal for foundations of stone and wood.

In preparing the plaster should be based on the following recommendations from professional masters:

- All materials are recommended to pass through a special strainer with cells of different sizes.

- To prepare the mixture should use a separate box with a depth of at least 10 mm and no more than 20 mm.

- Whichever solution you choose to finish the walls, it will have to be thoroughly mixed to get a homogeneous mass without lumps and seals. To do this, you can use a special paddle made of wood, having a length of about 1 m. If the structure of the mixture is heterogeneous, then the material will not “catch” with the overlap and will be of poor quality.

- Having mixed plaster, be convinced that it has the sufficient level of fat content. For this purpose, it is necessary to poke the mixture into the mixture. A quality solution will stick to the instrument a little. If the prepared plaster sticks too tightly to the oar, then it is necessary to add aggregate to it to reduce the level of its fat content. If the composition, on the contrary, is not glued at all, then it is necessary to add a component with a binder to it.

Let's take a closer look at how to prepare different solutions.

For cement-lime Kinds of plaster will require 1 part of cement, 3-5 parts of sand and 1 part of lime.

- It is necessary to take quicklime-pot and put it in a bucket. Remember that plastic packaging is not suitable for this.

- Pour water into the bucket at room temperature. Pour it so that it completely covers the lime layer.

- Now it is necessary rather to cover the bucket with a lid and press it down with something heavy, because in the conditions of boiling the lime often flows out through the edges of the dish.

- After that, you need to wait until the chemical reaction of all components of the composition stops.

- Next, you need to strain the mixture through ordinary gauze.

- After a day, this lime mortar may be used for plastering floors in the room.

- Then prepare a dry sand-cement mix (1 to 3).

- Pour the lime mixture into a container with dry ingredients and mix thoroughly until the mortar is smooth.

For the manufacture of lime mortar You will need 1 part lime mix and 3 parts sand.

- The lime should be “quenched” with the help of water, so that a quality solution will eventually emerge.

- Add water and sand to the lime container - these components will make it easier to apply the compound on the substrate.

- Stir the solution thoroughly so that no lumps or sticky pieces are left in it.

- Throw in the remains of sand in small portions. At the same time pour water.

- The readiness of the composition can be determined by its appearance - it must have a normal fat content and an average level of density.

In plaster and lime plaster 1 part of gypsum in a dry form, as well as 3 parts of a special dough from lime are included. This solution should be applied immediately after preparation, as it dries very quickly.

- First dissolve dry gypsum with water. As a result, you should get a lot like a dough.

- Add a solution of lime to the first component and mix well.

How to set the beacons?

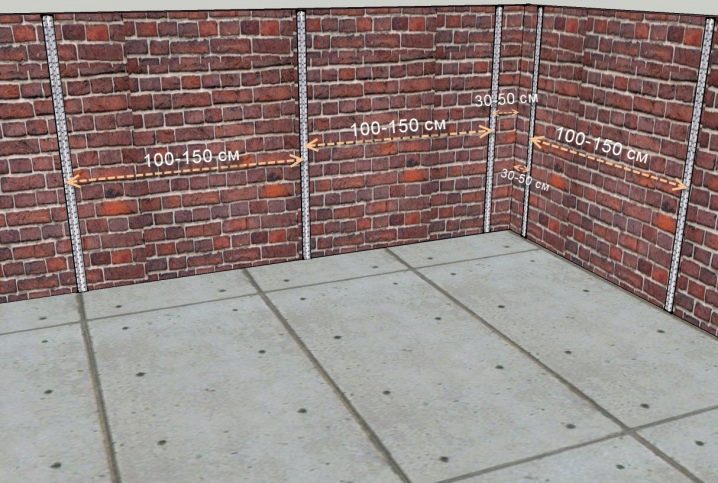

Lighthouses are necessary in order to achieve ideally flat surfaces of the walls; these details are exposed at the building level. As a rule, metal guides are used as beacons, they are attached to the walls with a simple gypsum mortar, as it dries quickly and becomes solid, thereby reliably holding the profile in the position you set for it.

It is necessary to maintain a certain distance when installing beacons. The optimal step is 1.5 m from each other. It is necessary that in the alignment process the rule follows two beacons located side by side. The vertical metal guides should be monitored with a plumb line. If your toolkit has only small and short levels,then instead of them you can use a bar of more impressive length, it is necessary to attach it to the guide and do it before the gypsum mortar is completely cured.

Training

Before applying the plaster, it is extremely important to properly prepare the base of the walls.

For this you need:

- Get rid of the former materials of finishing and coatings on a draft basis. Any paint, wallpaper or old decorative plaster should be removed. The starting layer of finish can be left in its place only if it is strong enough, otherwise it must be knocked off the foundation.

- Further it is necessary to knock the basis by means of the hammer. This is necessary to identify weak areas that require patching with putty or cement-sand compound.

- If there are metal parts in the wall, such as nails or screws, they must be removed. As for the reinforcement, it is cut with the help of the grinder and covered with an agent with anticorrosive properties.

- Do not start applying the solution without covering the furniture and other objects with film.

- Next, you need to apply a primer on the walls.This stage should not be neglected, since the lifetime of the plaster directly depends on it.

The primer is not only necessary to ensure the durability of the plaster, it also acts as an antiseptic layer and improves the ventilation of finishing materials. It is recommended to use a deep penetration soil for brick and concrete bases, and the usual “Betonokontakt” is quite suitable for simple and smooth foundations.

Acquired primer must be poured into the paint container. Then you need to dip into it a construction brush or roller, carefully squeeze the tool on a special canvas, installed directly on the dishes, and then process the entire area of the existing grounds. Do not forget that after applying the starting layer, you need to wait 2-3 hours, and then repeat the procedure again.

After this overlap should be left to dry for 10-12 hours. After treating the basics with primer, you can install beacons.

Drawing

After thoroughly preparing the bases, as well as their primer, you can proceed directly to applying the plaster. This work is not too complicated, and a home master, who does not have a wealth of experience in such matters, can cope with it.

Consider the process of applying plaster on the example of a gypsum mortar:

- First you need to properly knead the solution with all the required components and prepare the necessary tools for the job. If the floors are made of brick or concrete, then before facing they should be wetted with water. Such coatings strongly absorb it, which is why plaster will not quickly gain strength until it is completely dry, which will lead to the appearance of unsightly cracks on it.

- It is advisable to cover the walls with a spray gun. If this is not in your toolkit, then this process can be done using a simple wet sponge.

The prepared solution can be applied to the walls in two ways:

- "Cape". By this version of the application more often experienced masters. With such work, the solution "is nakidyvaetsya" on the surface of the base, and then stretched to the desired scale. For an inexperienced user it’s better to refuse such a method.

- A beginner should type the mixture on a wide spatula and move it to the surface of the base, then stretch it with a special tool - trowel.

Next, you need to take the rule and fix it perpendicular to the beacons.Run this device from the bottom up, making light zigzag movements. The pointed part of the rule will cut off the extra plaster, which can then be used to close the remaining gaps. If in the process of applying plaster air bubbles were formed, then the mixture should be removed from these places, and then applied again and thoroughly leveled. At the end of the finishing work, you should repeat the rule on the base, but now you can just lead the tool from the bottom up. It is recommended to carry out this procedure up to 5 times, as a result you should have a perfectly smooth and neat surface.

At the end of all the works, only places in the corners, as well as near the floor and ceiling, remain untreated. These areas need to be finished only after complete drying of the remaining area.

Finishing corners and areas near the floor and ceiling

These works are the final. Gypsum plaster should be applied as quickly as possible to corners and areas near the floor and ceiling.

Finishing the remaining areas is recommended to start from the ceiling. To do this, you need to prepare the solution again and stick to the same consistency,as in the decoration of the main surfaces. The resulting solution should be typed on a narrow spatula, and then gently stretch it. If you get a slight overlap - do not be afraid. Then you can go on it with sandpaper. Similarly, the unfinished areas near the floor should be trimmed. The remaining plastered areas must also be leveled using the rule, removing excess decorative material. Corners must be processed using a similar technology, however, it is worthwhile to constantly monitor the perpendicularity of the floors with the help of a square. In this case, instead of the beacons, the reference point will be the already finished wall surface.

At the end of all the works, you should make sure that there are no cracks on the walls, if they still formed, then they should be sealed with liquid composition and leveled with a rule. Only after these actions can you remove all the beacons, and the resulting shafts seal up and leveled. After that, the plastered surface must be sanded with sandpaper.

Manufacturers

Among the most famous and popular manufacturers, producing high-quality and durable plaster, It is worth to highlight the following major firms:

- Knauf (Germany).

- Ceresit (Germany).

- "Miners" (Russia).

- Volma (Russia).

- Weber Betonit (France).

- Silk Plaster (Russia).

Reviews

Most consumers buy plaster from foreign brands. As a rule, the quality of the products suits them completely - with rare exceptions: more often people are not upset by the poor quality of the resulting coatings, but by the cost of finishing mixtures. For example, the products of the French brand Weber Betonit or a large German company Knauf is not cheap. It is also worth noting that there are quite a lot of cheap imitations of plaster mixes of these brands in stores. Buyers confronted with such products are frustrated with their use.

Consumers point out the good quality of Russian plasters, but very often they shrink a little, and often cost more than foreign blends.

Tips and tricks

Experts recommend using exclusively high-quality and branded materials for decoration. Do not look for too cheap mixtures, as they, as a rule, have weak adhesion, serve not for long and give significant shrinkage.

Do not neglect the preparation of the base for the application of plaster, otherwise the finish may lie carelessly and not enough "grappled" with the base.

Choose vapor-permeable and moisture-proof blends.Such compositions are long lasting and are resistant to wear. In addition, dangerous bacteria or mold and fungus will not multiply on their surface.

Be careful when adding color to the plaster mixture: if it is too much, the result will not please you - the composition will be too bright.

On the features and intricacies of the process of plaster walls, see the following video.