What material to choose a classic desk?

Modern manufacturers represented a wide range of desks. Due to the huge variety of textures and designs, each consumer will be able to choose a model to his own taste and wallet.

Benefits

Written classic tables are quite popular and for many years do not go out of fashion.

These convenient and versatile models have the following advantages:

- Ecological safety of products is ensured through the use of natural materials.

- The design of the tables allows ergonomic use of space, successfully combining the storage area with the workplace.

- The chic appearance and use of expensive materials and elements of decoration in the manufacture of tables give the room a solid look and indicate the high status and wealth of the owners of the house.

- Good maintainability of wooden classic tables allows you to independently restore the damaged surface.

Species

Written classic tables are available in a huge range. By design and functional properties of the product are divided into the following types:

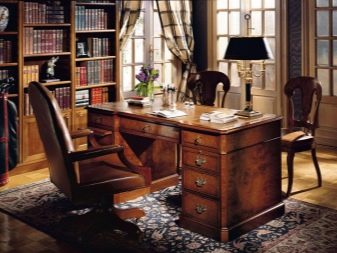

- Table with pedestal. The model can have one or two spacious cabinets, which can be equipped with shelves and internal drawers. The depth of the cabinet usually corresponds to the depth of the tabletop and is 70-80 cm. The advantage of this design is the presence of a spacious storage area, which is very convenient when working with a large amount of documentation and literature. The downside of the pedestal tables is a lot of weight and complexity when conducting wet floor cleaning.

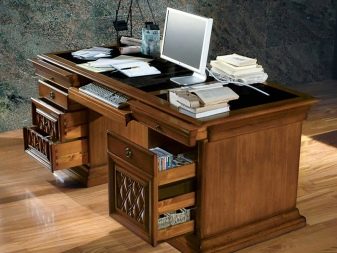

- Table with drawers. Model looks similar to tumbovye products. The boxes are arranged vertically (one above the other) and can be both single row and double row. The advantage of such tables is the capacity and the ability to sort and separate storage of stationery, office, books and documentation.The disadvantages include cumbersome and heavy weight design.

- Table with add-in. This model is characterized by the presence of additional vertically arranged shelves, located above the table top, as well as having both deaf and open design. The advantage of such products is a comfortable placement of various items, free space under the table top, not interfering with the cleaning of the room and stylish appearance. The minus design is the impossibility of placing such a table in front of the window.

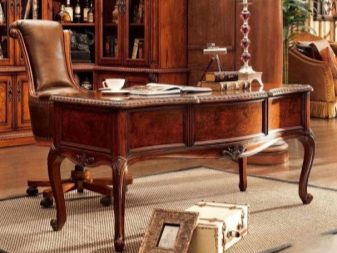

- Table with drawers on long legs. This is a very elegant model. The legs often have a curved shape that looks quite elegant and unusual. The drawers are located under the worktop horizontally and have a small height. Suitable for storing pens and small items. This design is lightweight and does not hide the space. The disadvantages include the small capacity of the drawers.

Materials

From the material from which the product is made, its weight, cost, appearance, strength and durability depend. For the manufacture of classic desks are used solid wood, MDF-plates, chipboard, fiberboard, metal and leather.

Solid wood

Tables are made from solid pine, walnut, birch, oak, larch, beech and mahogany. Due to its natural origin, the material is environmentally safe, hygienic and hypoallergenic.

The ability of the tree to be well painted in different colors allows you to produce products in a wide range of colors, which makes it possible to choose the table for any shade of the interior.

For a classic style, products with dark lacquered surfaces, decorated with carvings and gold-plated elements are suitable. For a gentle Provence, a white wooden table of simple shape with a matte table top will be a good option.

Classic tables can be well combined with some interiors. For example, a light model with imitation of rough wood processing, outlines of knots and a clear pattern of wood fibers will suit the rustic style. When you design an African ethnic style, you can pay attention to the bright yellow and red models that can be made in lacquer and matte versions. For the Scandinavian direction, a light beige table with well-visible annual wood rings and the absence of massive side drawers would be a good solution.

The leaders in the production of furniture from solid wood are Italy and Indonesia.Woodworking craftsmen manually perform complex ornate patterns, so that each model is unique and inimitable. Exclusive copies of the table surface is decorated with natural leather, which may have different shades. Also characteristic feature of Italian desks are curved long legs.

Such products look luxurious and elegant and serve as an independent element of home design.

Products from solid wood are well amenable to restoration and repair, which allows you to independently update the surface of the tabletop by grinding and varnishing. The disadvantage of wooden desks is their large weight, poor mobility and high price. Lacquered surfaces are sensitive to mechanical and thermal effects: a mug of hot tea leaves thermal circles on the tabletop, and moving heavy objects, such as office equipment, across the table - stripes and scratches.

Rattan is also used in the manufacture of desks. The advantages of such models is their lightness, mobility and aesthetics.The disadvantages include difficulties in care and intolerance to high temperatures.

MDF plates

Due to environmental friendliness and (in comparison with solid wood) lower price, the material is the most common type of raw material used for the manufacture of desks. The plate consists of small wood shavings, pressed by the dry method when exposed to high pressure and temperature. In the role of a binder component is carbamide resin.

Models made of MDF-plates are distinguished by high structural strength and high moisture resistance. The structure of the material allows to decorate the surface with patterned and carved elements.

Chipboard is also a popular material for the manufacture of classic desks. Consists of compressed sawdust, connected with the composition, which includes formaldehyde. This is a volatile compound that can stand out from the chipboard for a dozen years.

When buying such a model, you must make sure that you have a certificate of conformity confirming the level of this substance that is acceptable and harmless to health.

If the accompanying documentation for the product is missing, then it is better to refuse to purchase such a table.

As a laminator chipboard used PVC film, which, due to the huge number of different colors and textures, perfectly imitates the structure of wood fibers and the color of natural wood. This allows you to produce products in a wide range with a wide variety of colors and design. Laminated models have high moisture resistance and increased durability, and their low cost makes them popular and in demand. The design flaws include the impossibility of making carved patterns and curved elements.

In addition to lamination, in the manufacture of classical desks using the technique of veneering. Veneer is a thin woody sheet made of natural wood. It is made of ash, maple, birch, oak, cherry, walnut, alder, pear, beech and elm. The material is absolutely eco-friendly and you can not visually distinguish it from the array of natural wood. It is widely used for cladding plate material in the production of furniture, which is not inferior to its natural counterparts.

On top of the veneer is varnished, the quality of which depends on the resistance of the surface to mechanical stress.

Veneered tables are much lighter than wood. They are highly durable and resistant to moisture. The material is beautiful and practical, does not need special care and has a long service life.

Veneer can be made not only from natural materials. Modern technologies make it possible to produce artificial veneered surfaces that are visually and tactilely indistinguishable from natural materials.

Criterias of choice

When choosing material for a desk, you must focus on the design and size of the room. In smaller spaces, it is better to choose a product of simple shapes with small drawers, and for huge work rooms made in classic or retro style, a massive model made of natural wood with large side pedestals and draw-out drawers will suit.

When choosing a classic desk, from whatever material it was made, it must be borne in mind that the size of the working surface can not be less than 70 cm in length and 60 cm in width, and the height of the table top should vary between 70-80 cm.

Desk can be made by hand. How to do this, see the next video.