How to make a folding chair with your own hands?

Many stores offer a wide variety of folding furniture. As a rule, it is necessary for outdoor recreation, hunting or fishing. It is compact and easily fits in the trunk of any car. If you need a folding chair of a certain size or of a specific material, but on the shelves there is no need, you can make it with your own hands. You do not need to be a carpenter and have a workshop, just enough small skills in handling a screwdriver and a hacksaw and the correct drawing.

Kinds

There are two types of folding chairs that can be made independently. The first is a chair without a back. It is the easiest to manufacture and does not require large material costs. The second - with the back. Here, the creation process takes a little longer, but the chair will be more comfortable and convenient to use.

This chair is suitable even for an apartment or cottage.Moreover, if you use fantasy, then you can add armrests or various supports for mugs or a telephone to it. But not only the back can be made different, for the legs of the chair, too, there are several options.

The most common - cross, but in addition to them, make straight and solid legs.

Materials for the base, each chooses based on their preferences.

Tree convenient for marking and manufacturing, does not require additional tools for the work, it gives the opportunity to decorate and give individuality to the product.

Of metal to make the legs easier, but you will need special tools, such as a handsaw and a drill, designed for this material.

To facilitate the design, you can make a chair from polypropylene pipes. This option will be light and durable, but is unlikely to sustain a large weight.

Chairs can be with different seats. Having chosen a tree for manufacturing, it is better to buy small slats or bars for the seat, you can arrange them at different distances from each other. Also suitable compacted plywood or chipboard. For metal legs, a good choice is fabric; both the seats and the backs are made of it.

To give preference is dense, waterproof fabrics; cotton and linen are more suitable if the chair is operated indoors.

Main characteristics

Any folding chair, homemade or purchased, must meet the standards in order not to spoil the rest or occupation of your favorite hobby.

Main qualities:

- convenience;

- security;

- strength;

- small dimensions;

- low weight;

- resilience;

- simple technology of creation and assembly.

The choice of “clamshell” for many depends, first of all, on its weight and dimensions, because no one wants to carry extra weight on itself or to look for a special place in the apartment for storage. Light will be the options with a fabric seat of pipes - plastic or hollow aluminum.

How to make?

Whatever business you want to start, proper preparation is important for a positive outcome. In the manufacture of furniture is better not to improvise, and prepare everything in advance. Decide on the place of work, for each stage, select a separate space. Tools and materials should be on hand.

Materials

Wood - the most affordable and inexpensive material for the manufacture of chairs.Breeds of wood that are perfect - oak, birch, beech, larch. They are dense, resistant to prolonged exposure to water and sun. Pine boards are not suitable because of their softness and low water repellent properties. The tree should not have knots, cracks, dark spots.

It will be suitable and metal. Duralumin or steel pipes - something from which it is possible to make a chair at home. Check them for chips, dents and other deformations.

Acceptable will purchase plumbing pipes made of polypropylene or polyvinyl chloride. They just cut, bend well, have different accessories in the form of corners and plugs.

In addition to the core, prepare additional materials needed in the work, for example:

- Means of fastening and connection: bolts, screws, screws, screws with washers and nuts;

- Glue;

- Wooden dowels;

- Steel bar;

- Fabric for seat and back;

- Other.

You can prepare any material for work yourself. Wood is treated with sandpaper and covered with special agents for additional protection. The edges of the pipes are also cleaned.

Required tools

Each material and complexity of making a model involves the use of a specific tool.

But in all cases you will need:

- Saws or jigsaw;

- Clamp designed to implement a smooth cut or at an angle;

- Roulette, building angle, ruler;

- Pencil or marker;

- Screwdrivers or screwdriver;

- Drill;

- Sandpaper or sanding machine.

Using metal, holes are made with special drills, you may also need a device for deforming pipes. To work with a cloth, you will need scissors, threads and a needle or a sewing machine.

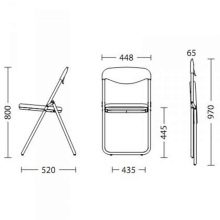

Drawing and Markup

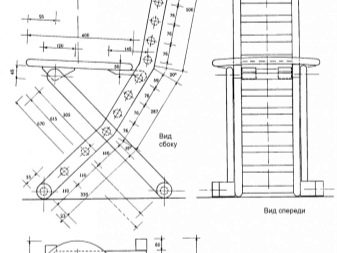

To speed up the process draw a drawing. Given the simple forms of folding chair, it is not difficult. You do not need to draw three-dimensional models, the main thing that is needed is the width and length of each part and their location.

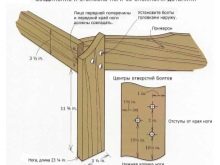

On the basis of the drawing, take the prepared materials and mark them with a tape measure, pencil or marker. It is necessary to measure not only the desired length, but also the place of the holes.

Assembly process

Backless

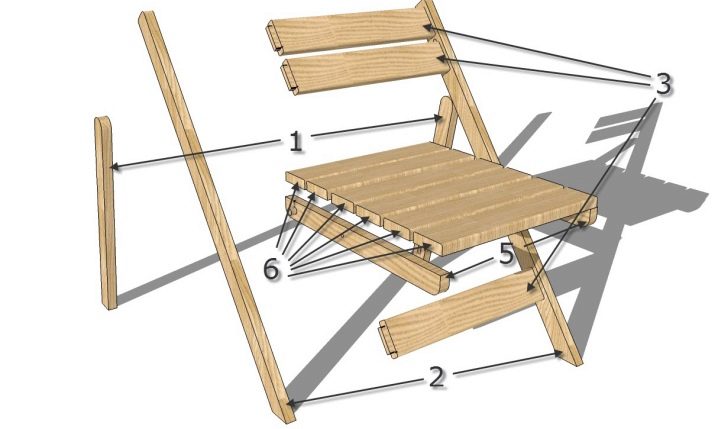

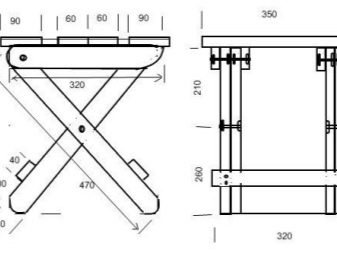

Elements of the chair: 8 bars for the legs and seats, four slats and two wings.

Lay out all the necessary elements in front of you. Take the blocks for the legs, install the axial bolts. Lower this axis by 2 cm from the wide bars for the seat so that the chair does not fall. Connect the seat rails with bolts, first to the legs inside, then outside, the sequence cannot be broken. These parts are articulated, fasten them together.Seat slats connect and fasten on the free ends. Screws screw the screws from the bottom of the legs, height - about 10 cm from the floor for a chair with a height of 35-40 cm.

Make sure that the middle bars do not touch, that the folding mechanism works. Secure the first timber to the crossbar outside, the second inside.

With backrest

The process of assembling a chair with a back involves working in several stages:

- Seat assembly. From the bars you need to make a foundation. The required number of rails need to be screwed to the resulting rectangle. Screws desirable to drown a little.

- The back of the chair. From the two bars and two slats make the frame back, the remaining slats place at equal distance in an empty space. The crossbar is fastened just below; we will fasten the seat to it later.

- The movable element in the form of crossbars is screwed to the rear legs from the bottom and top.

- The lower crossbar is bolted to the main frame, and the upper crossbar is attached to the back in the same way.

- Bolt the seat to the crossbar in the middle of the backrest.

If the seat of the chair is not made of slats, but of fabric, then in the first stage a pre-sewn cover is tensioned onto the frame instead of slats.

Metal or plastic

The easiest option is a stool on 4 supports. The manufacturing scheme of plastic pipes is simple. The pipe is cut into 8 parts: 4 long and 4 short. Long connect the letter "X" with bolts.

After these bolts are manufactured, it will be possible to adjust the chair so that it is easily folded. Short corners at the top and bottom with plastic corners attached to the legs. This is the frame of the chair. It remains only to take a suitable cloth type tarpaulin and sew a seat out of it.

In order for the chair not to disperse, make a strip of the same fabric, fold it in half and sew it to the lower crossbars of the chair.

On the basis of this chair, you can make an option with a backboard by attaching a frame of metal or plastic tubes to the upper crossbar. The back itself, like the seat, is made of cloth.

Metal can make a chair on three legs. For this you need 3 tubes of the same length and a triangular piece of cloth or leather. The optimum height of the chair can be made of pipes 60 cm long.

Begin work by drilling holes at a height of 25 cm on each pipe. Then make holes for mounting the seat material. Now take the two legs and bolt them together,between the tubes should be a second bolt with a loop. With it, fasten the third leg.

No need to tighten too much so that the chair folds loose. To secure the seat at the edges, holes should be made that fit the diameter of the legs.

You can fix them with special plugs, the same should be put on the other side of the pipe so that dirt and moisture do not get inside.

Making a folding chair with your own hands is not difficult, it is enough to have a good drawing and high-quality materials. The above options are the easiest to make. Based on these standard models, you can develop your own, suitable for the interior of the villa or kitchen. Add rich fabrics, paint the materials in bright colors, and even the usual fishing chair will be a bright accent in the room.

On how to make a wooden folding chair to give, see the following video.