Gypsum mix: types and application in construction

Regardless of the choice of materials for finishing the premises indoors, they all involve drawing on smooth walls. The easiest way to cope with coating defects is to use gypsum plaster. It is about its composition and performance characteristics, the intricacies of selection and application and will be discussed in this article.

Special features

Gypsum mix is a dry composition for dilution with water. The main component of the mixture is calcium sulfate hydrate, known as gypsum plaster. It is produced in the process of roasting a gypsum stone and its subsequent grinding to the state of small chips (similarly, by crushing marble, a composition for the manufacture of artificial stone is obtained).

Lack of shrinkage guarantees a smooth, high-quality surface without cracks., and high adhesion rates make it possible to abandon the use of reinforcing mesh. It may be necessary only in newly constructed buildings, the design of which shrinks. The thickness of the layer of gypsum plaster can be quite impressive - up to 5 cm.

But even with such a layer thickness, the weight of the coating is small, so it does not give an excessive load on the supporting structures, and therefore does not require strengthening the base.

Gypsum-trimmed walls are better than concrete, retain heat and retain sounds.

Finally, the treated surface is aesthetically attractive, smooth, without grainy inclusions.

Some speak of a higher cost of gypsum-based product compared with concrete-cement analogues. However, this can not be considered a minus, since 1 square. m consumes up to 10 kg of gypsum mix and up to 16 kg - cement-sand. In other words, the higher price is leveled by a lower specific gravity of the mixture and, accordingly, by a more economical consumption.

A noticeable disadvantage in some cases can be considered a more rapid setting of gypsum. This fact must be taken into account when working - immediately smooth the applied plaster, do not dilute it in too large volumes.

Packing

In addition, the composition includes components such as:

- perlite, foam glass, vermiculite - reduce the heat transfer of the material, and at the same time its weight;

- lime, white or metal salts, the task of which is to ensure the whiteness of the mixture;

- additives that regulate the rate of setting and drying of the coating;

- strength-enhancing components.

The product is completely natural, and therefore environmentally friendly. In addition, the gypsum coating is hygroscopic, that is, it takes and removes excess moisture from the room, which contributes to the optimal microclimate.

Features of the composition and properties of the product regulates GOST 31377-2008, according to which the compressive strength of the material is 2.5 Pa (dry). It has high vapor permeability and thermal conductivity, does not shrink.

The advantages and disadvantages of the product due to the characteristics of the composition. So, due to the high ductility, the material is characterized by ease of application. This process is significantly easier than a similar procedure when using other types of plaster.

Kinds

The following types of gypsum-based compositions are distinguished:

- plastering - designed for rough alignment of walls, coarse-grained;

- putty - light putty for interior work - for finishing wall leveling;

- assembly (dry) mix - is used when mounting internal partitions made of gypsum boards, leveling plasterboard sheets and plates;

- Hypsopolymer - assembly frost-resistant mixture with enhanced strength characteristics due to the presence of polymers in the composition;

- a mixture of trowel "perel" composition for filling joints and voids;

- self-leveling mixture for the floor - cement-plaster mix for the floor, its alignment.

For easy storage, transportation and use, the dry mix is packed in strong paper bags with a polyethylene inner layer - the so-called kraft bags. Their weight from different manufacturers may vary. The bags of 15 and 30 kg are considered universal, and they are most often purchased. However, there are "intermediate" options - bags of 5, 20 and 25 kg.

The shelf life of the mixture in the unpacked bag is 6 months. After that, even while maintaining the integrity of the package, the plaster composition absorbs water and loses its performance characteristics. Store the product in a dry place, avoiding damage to the original packaging.

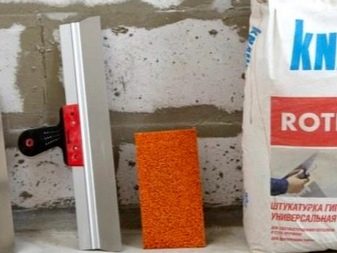

Tool

In addition to the mixture, you will need a construction mixer to work with which the solution is kneaded. Its use allows you to quickly get a homogeneous, lump-free mixture of the desired consistency. The correct mixing of the solution is one of the components of the ease of blending and the quality of the coating.

A spatula is required for applying the mortar, and a metal or plastic grater for grouting and glossing the surface. If a thin wallpaper is supposed to be stuck on top of the plastered surfaces, then it is required to walk on it with a trowel. It is a metal or rubber base.

When working with textured or relief plasters, rubber rollers are also used, on which the surface is patterned. The available tools allow you to create an interesting texture - a broom, crumpled paper, cloth, brushes, etc.

Selection and application

The mixture is designed for interior decoration. The most common types of coatings are walls and ceilings. The main purpose of the material is the alignment of surfaces, the elimination of small defects and differences in the height of surfaces.

The mixture is intended for use in rooms of normal humidity, it is not used for exterior cladding of facades. However, with additional priming composition is suitable for applying in the bathroom and in the kitchen. For wetter rooms, it is better to choose a hydrophobic coating.

In general, the material is universal, because it fits perfectly on the following surfaces:

- cement plaster, concrete walls (true, they are pre-treated with concrete contact);

- clay walls;

- brickwork;

- on cellular concrete blocks (foam and aerated concrete), expanded clay-concrete;

- old gypsum plaster subject to the requirements of its high strength.

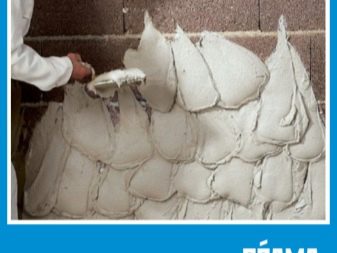

Plaster solution can be applied by machine or manually. When leveling the walls in the apartment usually resort to manual application.

Layer thickness is 3-5 cm, the next layer can be applied only after the previous one has dried. Alignment of the coating is carried out by beacons, that is, the thickness of the gypsum layer is equal to the height of the beacons. To smooth the surface and hide the transitions between layers allows grouting.

After drying, the plastered surfaces are to be applied with a primer, which will strengthen the layer and eliminate its shedding.If plastered walls are subject to painting or wallpapering, they must be covered with a layer of putty. During the drying of the layer, indoor drafts, exposure to direct sunlight are unacceptable.

How to do it yourself?

If necessary, the gypsum mixture can be prepared personally, especially since the recipe is quite simple. The main components are gypsum and water. However, if you use only them, the mixture will quickly harden, making it impossible to work with it.

To slow down the reaction between the components allows the introduction of plasticizers. The latter can be lime, diluted in half with water, PVA glue, citric or tartaric acid or special liquids. They can be found in hardware stores. In addition to increasing the time of mass setting, their use allows avoiding cracking of the plastered surface.

There are several recipes for the preparation of a plaster mix, with all the proportions of the main components being identical. Usually, for 1.5 kg of gypsum (gypsum-lime powder), 1 liter of water is taken, after which a plasticizer is added (5-10% of the total volume).

It is possible to make waterproof plaster, or rather, to give it moisture-resistant characteristics, by carrying a high penetration acrylic primer on top of it. If the plaster is applied under the tile, then its moisture resistance can be ensured with the help of concrete contact.

Manufacturers and reviews

Knauf "Rotband", "Miners", "Volma Sloy" mixtures are popular with domestic consumers. In general, the compositions are similar in quality and performance, only some of them cannot be used in rooms with high humidity.

The confidence of buyers won the universal mix Knauf from the German brand with more than half a century of history. The product "Rotband" is supplied in bags of 5, 10, 25 and 30 kg and is a dry mix.

Other mixtures of this manufacturer (“HP Start”, “Goldband”) according to user feedback are quite dense, which complicates the process of working with them.

The demand for the product due to its versatility: suitable for concrete, polystyrene foam, brick surfaces. In addition, it can be used in the kitchen and in the bathroom. The maximum allowable layer thickness for the ceiling is 1.5 cm, for walls and other coatings - 5 cm; minimum - about 5 cm.The consumption of the composition is average, not too large - about 8.5 kg / m2 provided that it is applied in 1 layer (2 times less than when using sand compositions).

The color of the mixture can be either snow-white or grayish, pinkish. The hue of the product does not affect its performance. The composition also contains additives responsible for improved adhesion. Due to this, the mixture shows good adhesion even on the ceiling with a layer thickness of up to 1.5 cm.

Special compounds of the composition contribute to the retention of moisture in the coating, so that in the drying process, even at high temperatures, the material does not crack.

When buying a mixture, make sure that the shelf life of the composition is not more than 6 months. Due to its high hygroscopicity, it absorbs moisture from the environment. After six months of storage, the moisture-saturated material loses its technical properties and crumples, which makes installation difficult. It is important that the bag was tightly closed.

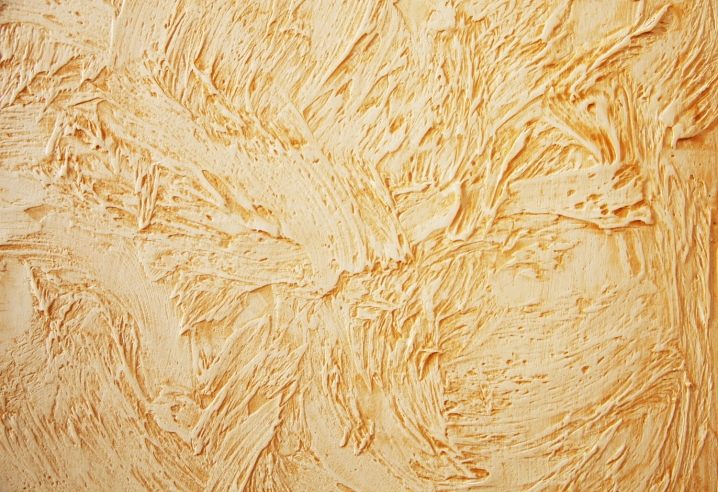

Successful examples and options

Finishing plaster plaster may be covered with interior paint. The surface can be perfectly flat or have a texture. In this case, the relief is applied on wet plaster.Depending on the materials used, a tap or other texture is obtained.

If you use special application techniques and special tinting, you can get surfaces that imitate natural materials - wood, concrete, brickwork.

It looks interesting plastered and painted surface that resembles textiles - velvet, leather, silk.

Gypsum mix is widely used in arts and crafts. For example, the decor of cans and bottles allows you to turn them into stylish interior accessories.

To learn how to properly prepare a plaster plaster mix, see the following video.