Quicklime: features and scope

Lime is a universal substance that, due to its extensive and diverse properties, can be used in almost any field of activity. It is of various types, depending on the selection criteria, and is divided into several varieties. Variants of preparation of solutions with its content are not very different from each other and do not cause difficulties, so this raw material can be used independently without the involvement of specialists.

Special features

Quicklime is calcium oxide obtained by burning calcium carbonate, it has a finely porous structure. Sometimes quicklime is called boiling pot.

Advantages over hydrated lime

It has many advantages in comparison with the quenched variety:

- high strength;

- absorbs less moisture;

- work with this material can be carried out in the winter;

- no waste;

- very extensive scope.

Quicklime is dangerous to human health, therefore, it is desirable to carry out work in open spaceusing protective equipment.

A good advantage of quicklime can be considered low cost in comparison with other mixtures. Lime material is resistant to temperature extremes, it does not crack, has antimicrobial properties.

Specifications

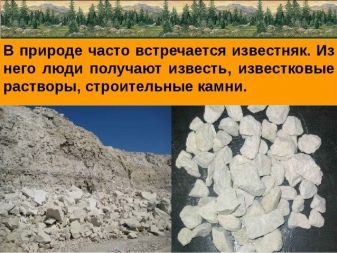

Lime is a substance that is often found in nature (mainly in rocks), and the manufacture of a product occurs with full compliance with established standards, because mixtures on such a basis must perform protective functions at a high level.

Ready lime should consist only of carbonate rocks (limestone) with a small clay content. Various additives and impurities are allowed in the composition of the material based on GOST, depending on the application.

Limestone looks very similar to chalk or coke, but they have different properties and are not interchangeable.To distinguish limestone from chalk, you can drop water on them. Mel will not give any reaction, but the limestone will begin to foam and release heat. If you use chalk to whitewash the walls, it will leave marks on clothing and surfaces that come into contact with the wall. Lime leaves no trace, so it is most often used to whitewash the walls.

Quicklime is divided into three grades (1, 2 and 3), and slaked lime is subdivided into 1st and 2nd grade. The exception is powdered quicklime, it is divided into two varieties and has additives. Other types are made without impurities.

By external physical indicators, for example, by color, you can determine the grade of the material. After heat treatment of limestone, quicklime is obtained, and if it is white, this means that the material contains no additives and is of high grade. In other cases, the material has a grayish color, most often it is dolomitic and hydraulic lime.

The manufacture of lime material consists of the extraction of the rocks themselves, their grinding to the required size and the subsequent roasting in special kilns.Currently, shaft and rotary tube furnaces are most often used, because they provide a uniform effect of temperature on the material and a continuous roasting process.

The strength of the raw material is influenced by the temperature during firing and the production process itself. There are three options for the strength of the finished product: hard burned, medium burnt and soft burnt lime.

Soft lime is very popular in construction due to such properties:

- the quenching process takes place quickly, in about 3 minutes;

- This material has a small size and low density.

Lime is a low-hazard class, but safety must be observed during transportation and storage. Since quicklime reacts violently with water, it is necessary to make sure that moisture does not get into the material.

The composition of lime most often includes various mineral additives that improve the properties of the material: granulated blast-furnace slags, quartz sand and other substances.

Kinds

There are two types of lime, which are distinguished by the amount of calcium silicates and alumoferrites of calcium in them: air and hydraulic.They perform various functions, for example, air accelerates the process of hardening of concrete, and hydraulic accelerates the reaction in water.

It is important that all fragments of a substance are of the same size. This moment indicates that the raw material is completely calcined in the furnace. If there are too large or too small pieces, they may not be completely heat-treated, and this will reduce the quality of the finished material.

By type of processing there are several types of material:

- quicklime (boil);

- burnt ground (powdered);

- hydrated hydrate - Ca (OH) 2;

- lime paste;

- milk of lime.

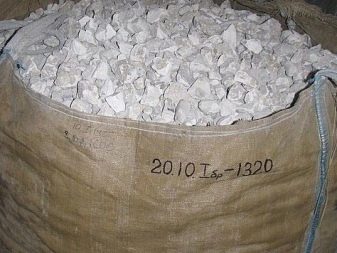

Lump lime

Lump lime is a mixture of lumps that differ in size. It consists of calcium oxide and magnesium, as well as materials such as calcium carbonate, aluminates, silicates. Magnesium or calcium ferrites, which are formed during firing of the raw materials, can be added.

Good concrete strength is ensured due to the fact that lump lime requires a very small amount of water (due to the fine grinding of the material) and practically does not form waste.

Ground lime

Ground lime has the same composition as the lump, but the difference is that the lumps of raw materials are ground much more and more thoroughly.

The main advantages of ground lime:

- strength;

- water resistance;

- fast hardening.

Calcium chloride or sulfuric acid is often used to increase or decrease the speed of hardening (gypsum material will also work).

Hydrated lime

Hydrated lime (also called fluff) is a slaked type of material with a highly dispersive composition. Quenching occurs by adding water to the lime raw materials. To prepare such a solution, from 70 to 100% water is added to the powder.

In order for lime to complete the quenching process, it must be placed in a special pit for 2-3 weeks. So she pick up the optimum strength and ductility. The minimum quench time is 36 hours. In order to prevent the burning of raw materials, it is advisable to add water gradually until the moment when steam is no longer evolved.

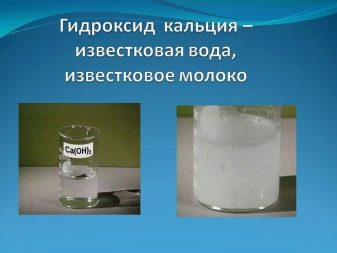

Lime dough is formed by adding enough water to form a plastic material. You can also find such a solution as lime milk (mainly used for whitewashing tree trunks).Lime milk is obtained by adding water with excess to the lime paste.

Types of formulations

Depending on the application, these types of compositions are distinguished:

- Building lime - it is added for the preparation of concrete and cement mixtures in order to increase the strength of the composition;

- Hydraulic - also used for the production of concrete, but low marks. Ideal for buildings that are located in areas with high humidity;

- Lump - mainly used to prepare a solution for whitewashing;

- Sadovaya - used in agriculture as a soil fertilizer, processing plants from insect pests, protection from rotting and improving growth, it is highly undesirable to use it simultaneously with other types of additives and fertilizers;

- Natrovaya - used in the chemical industry and in medicine;

- Chlorine - used as a disinfectant and for water purification.

Calcification of lime by time of quenching

- quick extinguishing (up to 8 minutes);

- srednegayaschayasya (up to 25 minutes)

- slow extinguishing (from 25 minutes).

Types of lime

Depending on the percentage of presence in the composition of magnesium oxide, there are such types of lime:

- calcium;

- magnesia;

- dolomitic.

Scope of application

Lime is used in many areas.

- In agriculture, lime is used to control pests, reduce the acidity of the soil, prevent the appearance of fungus, supplement feeding of animals, improve the workability of the earth, replenish the stock of calcium and phosphorus. It is best to handle heavy lime with quicklime. Lime is common as a material for whitewashing trees and processing plants.

- Building. It is used to accelerate the hardening of cement and impart plasticity to the composition, participates in the production of thermal insulating materials and dry building mixtures, serves as a link in building structures.

- Ferrous metallurgy - enriches ferrous and polymetallic ores.

- Chemical industry - used in the paint, perfume and pharmaceutical industries. It is used as a reagent and as a neutralizer for acid tars.

- Pulp and paper industry.

- Textile industry.

Chloric lime is used to disinfect and clean public places., as it has disinfecting properties.Quicklime is used even in the food industry to mix substances, and milk of lime is used to make sugar. Soda lime is used in medicine (artificial lung ventilation or for anesthesia) and for respiratory systems (scuba, respirators, and other devices).

The coating with lime mortar of wooden surfaces protects them from the processes of decay and the occurrence of fires.

How to use?

In the preparation of lime mortar is important to ensure the safe interaction of raw materials with water for humans. It is advisable to work in a well-ventilated area, and preferably in open space. Since the substances used are chemistry, it is necessary to adhere to the safety rules when working with such materials.

Powder can be used both in dry and liquid form. To prepare a liquid solution, the powder is poured into a container and filled with water. The solution must be mixed and diluted to the desired consistency.

For whitewashing trees, raw materials are diluted with water and applied with a wide brush to the tree trunk. But because of the liquid consistency of the solution, the barrel will have to be processed several times.In order to reduce the time of work, you can add clay, milk, PVA glue to the solution. These ingredients will make the mixture thick and viscous, it will evenly lie on the surface. Before treating the tree, remove all dead layers of bark, without damaging the trunk.

To protect plants from the fungus, you can use soda ash instead of lime, because the soda is faster and completely dissolved in water.

Do not process the soil with too much lime, as it will become alkaline, which also will not contribute to good growth and development of plants. It is impossible to use manure and lime at the same time, because such a combination will prevent the formation of useful substances.

Before you use bleach, you need to check the reaction of the surface. To do this, you can treat a small area, and if it remains intact after about 10 minutes, then you can use bleach for the entire surface. First, water is added to the raw materials in a small amount and stirred to the state of sour cream, and then gradually water is added, also stirring, until a liquid solution is formed.In dry form, bleach is used only on wet surfaces.

In construction, it is recommended to use burnt ground lime for the manufacture of plasters, cinder concrete, and painting elements. In other cases, used slaked lime, which, due to moisture resistance, prevents the formation of mold.

Pushonka has a wide scope of application: from domestic needs to construction. To prepare the fluff it is necessary to pour raw materials into a metal container without rust (or into a plastic one) and gradually add water, stirring the solution. Once the mixture is ready, you must leave it to infuse for several hours or days. The longer it will stand, the higher its quality and strength index will be.

Tips

- If necessary, long-term store ready lime solution, you can periodically add water to it. Initially, water is added until the material no longer absorbs it. This rule does not apply to the preparation of milk of lime.

- The optimum depth of lime in the soil is 20 cm, but if the dose of fertilizer is small, then the depth should be less.On top of the lime is covered with a layer of sand. For storage in winter, it is recommended to pour another layer of soil 70 cm high on top of a layer of sand.

- Before applying to any surfaces (wood, concrete, cement, metal) it is necessary to completely remove contamination, grease, defects and rust from them.

- It may happen that the lime got into an unnecessary area and it should be washed off. To do this, first of all, it is necessary to moisten this area abundantly, wait for a good dissolution of lime, and then remove the material using a rigid metal sponge. If necessary, repeat these steps. There are already ready-made solutions for such needs, for example, Guard Industrie or Space. You can use homemade solutions based on hydrochloric acid.

- It is not recommended to carry out a primer before whitewashing, as the lime will not be fixed on such a basis. It is also desirable to produce whitewashing with brushes, rather than with an airbrush. The brush will distribute the lime mortar better, and the finishing will be more qualitative.

- The higher the period of exposure of the finished mixture, the better it will perform its functions.

- For the preparation of mortar is best to add more and sand.

- This material is not suitable for making cement for a fireplace or stove, since carbon dioxide is released when heated.

- To obtain insulation, you can add sawdust and gypsum to the fluff. In other cases, the lime mortar should not contain sawdust, lumps and other inclusions in order to evenly and integrally cover the surface.

- Bleach must be stored in a dark room, because under the influence of the sun's rays, part of the active chlorine is lost.

For information on how to determine the quality of lime, see the following video.