Diffusers for fixtures

Currently, there is a wide variety of fixtures with different characteristics, differing in style and types of lighting. A rather important function is performed by diffusers for luminaires, which ensure uniform distribution of the light beam rays.

Special features

Diffusers, or ceiling, are an optional part of the lamp, they perform a secondary role, but there are situations where their presence is simply necessary. For example, to protect against excessive lighting, as this product is a kind of light filter, or a change in the design of the lighting fixture. In these situations it is much more rational to install a different ceiling than to get a new lamp.

The diffuser as a construction element of the lighting device performs a number of important functions:

- Distributes light from the main source, creating uniform illumination.

- Protects eyes from bright light.

- Performs the function of protecting the lamp from all kinds of mechanical effects, as well as dust, moisture and insects.

- It is a great addition to the overall interior design.

An important characteristic of luminaires with diffusers, associated with the field of application of devices, is the scattering angle, which is understood as the area where the light flows from the source.

LED luminaires with different scattering angles make it possible to create complex lighting devices that allow solving several design problems at the same time.

Manufacturing material

For the manufacture of diffusers use a variety of materials, each of which affects the degree of refraction and scattering of light radiation. Also, some properties of the ceiling depend on the quality of the material - this is both durability, and resistance to mechanical stress, and reliability, and frost resistance.

The lampshade material can be plain or acrylic glass, thermoplastic, solid polycarbonate, light-diffusing plastic, various metals, etc.

Ceiling light from glass used for a long time, and it’s no secret to anyone the advantages and disadvantages of such products. The main disadvantage of glass shades is their fragility, but the beautiful view of the design makes this material quite popular.

In some cases, products are used as a diffuser. from crystal. This is quite an expensive pleasure, and not everyone can afford such luxury.

Thermoplastic diffusers for a long time retain the original appearance, provide constant color of the ceiling for a long period due to light-stabilizing additives.

Monolithic polycarbonate - it is the most durable material that provides reliable protection against mechanical stress, is quite resistant to high temperatures. From a single sheet, you can create a ceiling of any shape and size. This is an inexpensive material with high transparency, but the aesthetic side leaves much to be desired.

In the production of metal diffusers, mainly aluminum and steelThey act as a reflector and also direct the flow of light.

Polyethylene terephthalate (PET) quite popular, although for some properties inferior to polycarbonate. The temperature limit determines its use as a ceiling for LED and fluorescent lamps.

Kinds

By type of construction, diffusers are divided into partially and completely closed. Fully enclosed ceiling to a greater extent protects against excessive lighting. Also diffusers can be opaque or transparent, have a smooth or corrugated surface.

On the market there are a large number of types of ceiling lamps with diffusing light, which are divided according to the texture of the material, but in practice the five main ones are more popular. They are made of polystyrene - Plexiglas, resistant to UV rays, maintaining transparency during the entire period of operation and characterized by a beautiful appearance.

There are such models of diffusers.

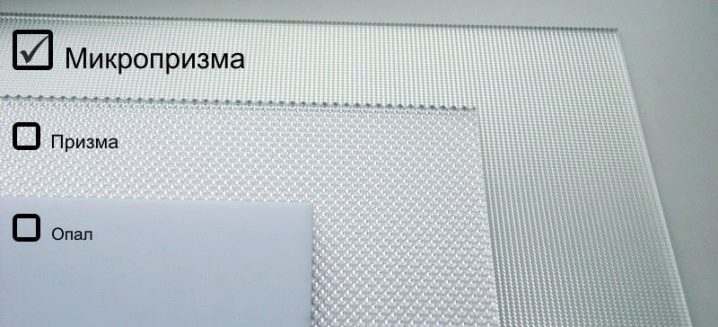

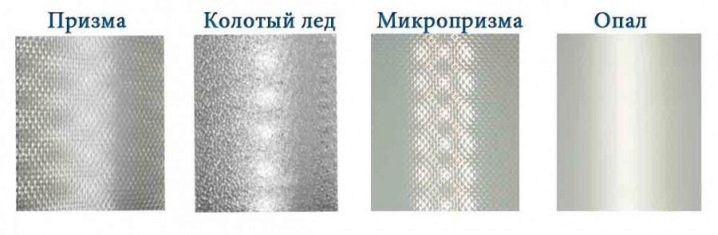

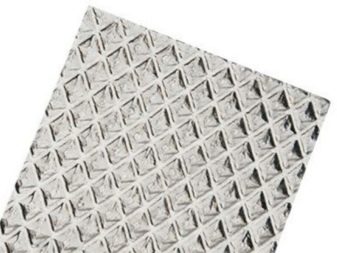

- "Prism" has a prismatic structure of the material, reduces the brightness and the degree of dispersion of the stream of light. The thickness of the material - 2.5 mm, light transmittance - 85%.Microprism - ceiling made of durable, durable polystyrene, having a small geometric pattern, thickness 2.0 mm, light transmittance - 83%.

- "Chipped ice" it looks like a “microprism” diffuser, but it has a different texture, creating the effect of crushed ice. Polystyrene thickness - 2.5 mm, light transmittance - 88%.

- "Honeycomb" It got its name due to the texture resembling a honeycomb, the thickness of the PMMA material is 3 mm, and the light transmission is 85%.

- "Pin-spot" It has a dotted structure, thickness - 2.5 mm, light transmittance - 89%.

- "Opal" it is distinguished by a matte surface that gives the light a slightly yellowish tint; it is used mainly for certain design purposes, the thickness is 1.5 mm, and the light transmittance is 73%.

How to choose?

When choosing a diffuser, first of all, it is necessary to determine the requirements for a lighting device. In any case, aesthetic data and safety of the lamp should be organically combined. Particular attention should be paid to the degree of light transmission. Depending on the place of use of the luminaire, it is necessary to take into account special requirements for the ceiling: the presence of protection from mechanical effects and adverse conditions, the level of fire safety.

Use incandescent bulbs more than the recommended power is strictly prohibited.

You can find out how to make a simple light diffuser with your own hands by watching the video below.