Features of the automatic machine for airing the greenhouse

Such a structure as a greenhouse must fully ensure acceptable conditions for the crops growing in it. The environment in which plants grow and develop in greenhouses has a number of specific features that relate to the maintenance, irrigation, microclimate, ventilation and other things. Since their ability to bear fruit depends on the combination of these factors, it is very important to choose the right device for automatic airing of the greenhouse.

Features of the device

The main requirement for such structures is the presence of a constant flow of fresh air, which will allow plants to create the optimum level of humidity and temperature. Gardeners and gardeners regularly face the task of arranging a system or plant,which will work indoors as a ventilator, since the air flow is responsible for the possibility of pollination during flowering. Today, the acquisition and installation of automatic devices for air ventilation will help to effectively solve this issue.

Characteristic technical and operational features are inherent to automatic machines for airing:

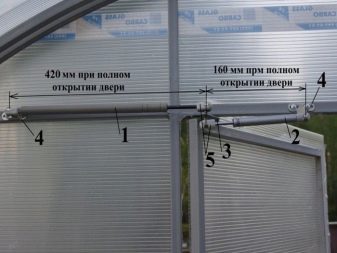

- size - the maximum length of the thermal actuator is 45 cm, the minimum is 33 cm;

- the apparatus can withstand wind loads up to 100 kg;

- to ensure productive work, the rod in the device must be treated every year with engine oil;

- the temperature at which the device can function smoothly varies in the range of +60 to -40 ° C;

- open vents at a temperature of + 24C;

- close at 22 ° C.

The use of systems for ventilation of greenhouses has a number of positive properties:

- the possibility of automating, no need for human presence;

- easy installation of the device;

- affordable cost of production;

- no dependence on the power supply in case of installation of autonomous systems of ventilation of greenhouses.

If you live near the greenhouse, it will be enough to open the windows every day, but an irregular visit to the building requires the installation of a certain system,which will act as an autovent. Automatics, assembled into a functioning device with their hands, or an acquired mechanism will help solve such a vital task.

Types of mechanisms

Machines for airing greenhouses, presented by modern domestic and foreign manufacturers, include a lot of different models.

By the fundamental criterion, which concerns the methods of functioning of devices, they can be classified as follows:

- autonomous systems group;

- volatile models.

The principle of operation unites these devices - a thermal actuator acts as a basis for ensuring productive work. In order to fulfill its tasks, electrical mechanisms must be provided with a power source. In its role can be an electric current or a solar battery. The operation of the electric drive controls the thermal relay, where the desired temperature is set, allowing the crops to develop properly in the greenhouse.

The principle of operation is reduced to the following scheme: the sensor, which is connected to the fan, transmits a signal that drives the slider.After that, the blades of the device begin to rotate, forcing fresh air, displacing the waste. This variant of ventilation is called forced ventilation of the room. It is very efficient and simple, and is often used in large-sized greenhouses, since the circulating power is quite serious. Automating has tremendous benefits for growing crops.

Models of devices that need recharge with electricity, have some drawbacks due to the characteristics of their mechanical devices.

- the high cost of devices associated with the need for tightness of internal components, since they contain electronics;

- the uselessness of devices as a result of a power outage at the site or a complete blackout of the room. However, the acquisition of a backup electrical unit will help to avoid situations involving power failure and device operation;

- when one component of the system becomes unusable, repair or replacement of the entire unit may be required.

In addition to the shortcomings of electrical systems, one can also highlight a number of advantages of mechanisms:

- high power devices;

- implementation of the task in the shortest possible time;

- compactness of the apparatus;

- high-tech products.

Autonomous mechanisms are divided into several groups.

Based on the system of the device, they are:

- hydraulic apparatus;

- pneumatic devices;

- bimetallic mechanisms for ventilation.

The functioning of the units is carried out through the use of hydraulic actuator and thermal actuator, working due to the properties of various substances to expand under the influence of temperature. In the thermal relay, specific parameters are set, based on which the apparatus functions. They can be simple or computer-controlled.

Two metal bands are used to assemble bimetallic apparatuses.having a different coefficient of expansion. They are connected to each other along the entire length, and upon thermal exposure (heating of the raw material), one product is extended and bent. Due to the impressive length of the metal strip provides a good force, sufficient to open the window. When the temperature in the room decreases, the plate will cool down and acquire its original dimensions, due to which the shutter closes.

The downside of such an apparatus for ventilation is the difficulty of selecting the correct temperature level for ventilation in the room.

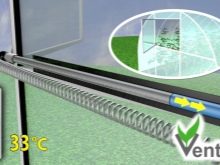

Hydraulic mechanisms perform ventilation by expanding the fluid in the hydraulic cylinder due to thermal effects. When heated, the oil increases in volume, thereby pushing out the piston, which is fixed with the vent. This phenomenon provides the opening of the transom and the ventilation of the greenhouse. As the air cools, the fluid cools and the piston retracts, thereby returning the flap to the closed position.

The disadvantages of such a device include a certain inertness of the liquid - it slowly changes its temperature and volume, which leads to a delayed reaction to a decrease in the overall temperature in the room. It is best to purchase such devices for installation in greenhouses, where the transom located at the top, for example, in dome structures. In these structures, the heated air is collected directly near the vents, and an overly cooled stream does not reach the plants quickly, therefore it cannot harm them.Such devices identify the temperature indicator only in the immediate vicinity of itself.

The high cost of the device also refers to the disadvantages.

The advantages of airing with the help of hydraulic devices include the following nuances:

- the ability to work in comfortable conditions;

- no unpleasant odors;

- independence from energy sources;

- easy assembly without the involvement of specialists;

- there is no need to always be near the facility to control climatic conditions.

If you opt for hydraulic automation for ventilation of greenhouses, it is worth considering the following important factors:

- devices in this category will need to be installed on each transom in the room;

- before acquiring an apparatus, it is worthwhile to become familiar with the power of lifting the vents, which the proposed apparatus provides;

- preliminary designate the maximum weight limit that the entire greenhouse structure can withstand.

The pneumatic regulator performs its task according to a similar principle with an apparatus that operates on a hydraulic mechanism.The only difference is that the air itself acts as a substance that must expand and power the device.

Pneumatic devices have some advantages:

- autonomy from any power source;

- low cost;

- high performance

The disadvantages include the following features:

- impressive dimensions;

- small work effort;

- power level is directly related to pressure in the atmosphere.

The operation of such types of devices for ventilation of greenhouses has its own nuances:

- it should be noted that the manufacturer sets certain limits on the angle of disclosure of the transom using mechanisms, taking into account its weight;

- hydraulic devices should not be installed in areas of the room where they will be exposed to direct sunlight. Since the device will react to the temperature that it will provide contact with the sun, and will not - to the internal temperature in the greenhouse. This will entail an illiterate adjustment of the microclimate, as a result of which the crops growing in the structure may die.

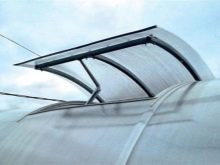

How to install?

The technology of installation of equipment for ventilation of greenhouses is not a complex and highly specialized process.

Installation work consists of several mandatory and alternate steps:

- first of all, you need to perform a number of preparatory work, which include a preliminary inspection of the vents for their easy and smooth opening. Making sure that the window structures are in good condition, you can proceed to the next step;

- at the top of the structure, whose work will be adjusted by the mechanism, you need to correctly identify and designate the place where the bracket will be located;

- the fastener is fixed to the sash with screws;

- the second bracket can be attached to the wall or window frame, also using screws;

- then the thermal drive is fixed to the spring, which ensures the transom to collapse.

Manufacturers: review and reviews

Based on the majority of reviews of owners of greenhouses, the most popular and effective automatic ventilation is the Dusya-San universal unit. It perfectly functions in constructions of any type.The device works on the principle of a gas shock absorber. The sensor is calibrated in the temperature range of + 16-25C, based on the optimum recommended temperature for the productive development of most greenhouse crops. Heating provides thermal expansion of the material, as a result of which the length of the device may increase up to 12 cm.

Technical conditions for the functioning of the Dusya-San apparatus:

- opening sash is 45 cm;

- the temperature at which the piston extends to a maximum is 30 ° C;

- 12 months warranty;

- the weight of the structure to be extended shall not exceed 7 kg.

Among the hydraulic devices for ventilation, stands out the unit "Ufopar-M". In fact, the apparatus is a steel cylinder in which the oil is located. The device operates due to the difference in the coefficients of thermal expansion of the metal and the substance. Due to the increase in temperature in the greenhouse, the oil is heated and expanded, which squeezes out the piston regulating the vent window. The device has positive feedback due to the possibility of regulating the temperature and the level of opening of the window sash.

Ufopar-M has the following technical characteristics:

- light weight of 1.3 kg;

- maximum force on the piston - 100 kg;

- maximum heating - + 80C;

- The warranty period is 5 years.

Univent is a machine for airing automatic type. It begins its work when the temperature inside rises to 17-26 C. The maximum opening occurs at the moment when the thermometer records the value of + 30С. The device easily opens the doors, which have a weight of 10 to 40 kg. The device is manufactured with a reinforced metal casing and a special system that allows using the device as a door vent for greenhouses.

Tips

To create the right conditions for ripening plants in a greenhouse, You can use several types of automatic room ventilation.

- provide ventilation through the arrangement of two transoms located nearby. Structures with a large area are equipped according to this principle without fail;

- through ventilation - is carried out with automatic opening of doors. Experts recommend this option for narrow structures;

- a mechanism built into the wall that will open the vents;

- device with temperature and humidity control sensors inside. Such a device can be made by hand.

All automatic openers for greenhouses are produced for use only for their intended purpose - that is, for installation on window and door structures in buildings. Therefore, they can not be disassembled and used for other purposes.

Experienced gardeners are not advised to arrange opening structures for ventilation near the entrance door.This advice avoids the formation of drafts that adversely affect developing cultures, especially young shoots. And also this arrangement can lead to a sharp slamming of the vents when auto-winding by gusts of strong wind, as a result of which the apparatus, which is installed on the doors or doors for ventilation, will become unusable. The ideal location of the vents will be the middle of the structure.

An overview of the thermal drive for ventilation of the greenhouse, see the video below.