What greenhouse to choose to give?

The prototypes of the current greenhouses were used in European countries from the XVI century, and the first buildings of glass and wood appeared in the English nobility after almost 100 years. Spread quickly in Russia, greenhouses were used to grow exotic fruits and plants. A little later, widespread plastic wrap. Today in the choice of material for the greenhouse there are a lot of innovations. About what kind of greenhouses are and what kind of structure is suitable for certain conditions, and will be discussed in this article.

Kinds

Among the variety of types of greenhouses you can find the right option depending on the pricing policy and quality. For example, by time and method of operation greenhouses are classified into:

Winter

The “speaking” name immediately indicates a paramount feature - due to the mandatory heating (solar energy, biofuel, technical means), vegetables, flowers and fruits can be grown in such a greenhouse year-round. The building can be either deepened into the ground or located on the surface, but regardless of this, its foundation must be an essential attribute.

The frame material is wood, brick, PVC or a metal base, and greenhouses are covered with polycarbonate or glazed. But combinations are also possible.

An important aspect of the winter buildings is the choice of their location.

- to build a greenhouse preferably in length from west to east (in this case, guaranteed maximum exposure to sunlight);

- easy access to the building;

- fencing from the wind, especially if natural conditions imply frequent gusts (it can be a structure or a hedge about two meters high and at least three sizes of the building height from the greenhouse).

Summer

As a rule, summer greenhouses are used from March to November.The microclimate in the building is provided by the penetration of sunlight, although the option of artificial heating due to cooling is possible. Compost, humus or manure acts as biofuel. The frame is made of wood, metal or plastic pipes. They are considered more economical, as they are covered with an inexpensive film and do not require a solid foundation and insulation. Grow in such greenhouses mainly seedlings or crops, implying special conditions of care.

By mobility greenhouses can be divided into mobile and stationary. A collapsible type of construction allows you to dismantle the structure, which is convenient for those who work in the country only in the warm season. The second variety is optimal for gardeners who visit sites year-round.

At the location of the structure can be detached and adjacent to the building. The second option is also often referred to as a wall greenhouse and provides that the wall of the house acts as a carrier for the greenhouse. The building most often attached to the house is lean-to, not prefabricated and is used during the cold season, which is why it must be equipped with a heating system.

Botanik

Depending on the model, greenhouses can also vary considerably.So, the Botanik structures are the only aluminum (non-corrosive) structures of a high quality level from the Russian manufacturer - the AlumVerk company. A feature of the company's concept for more than 10 years is a combination of high-quality reliable range and a wide range of additional options. The manufacturer focuses on the typical weather conditions for the regions.

Among other distinguishing features:

- high-quality ventilators of own production, which guarantee effective ventilation;

- rational compartment type of door, which is shifted to the side, which allows to increase the useful space for the beds;

- expanded color range for the frame and seal of the greenhouse;

- high reliability and rigidity of the structure due to the complexity of the cross-section of profiles and the optimal angle of inclination of the roof;

- durable and effective sealant from special polymers, the effectiveness of which is tested in the range from -50 º to + 50 º;

- The material used prevents glass from rattling, sealing the entire area of the room;

- the ability to install additional options due to the upgraded carrier profile, which is a slot design;

- the possibility of using decorative elements of decoration (ebb around the perimeter, skates on the roof, individual glazing);

- advanced fastening system.

Basic models «Botanik».

- "Mini" - with a width of 2.1 m for compact areas or a small number of cultivated plants. Cost - from 40 thousand rubles.

- "Standard" with an optimum width of 2.8 m for two beds. Cost - from 44 thousand rubles.

- "Maximum" - with a width of 3.68 m provides ample workspace. Cost - from 53 thousand rubles.

- With tambour "T" allows you to expand the space at the expense of a convenient and prestigious side entrance. Cost - from 108 thousand rubles.

Arrow

The greenhouse "Strelka" is a polycarbonate teardrop-shaped construction of the Moscow manufacturer Vol. Due to its shape, it prevents the accumulation of precipitation by rolling it off the roof. Greenhouse producers "Dachnaya Arrow" point to its unique properties characteristic only of this design, which has no analogues:

- Additional thermal insulation due to air formed in the cells of the stiffener joints.

- The presence of the foundation is not required.

- Polycarbonate coating protects from the scorching sun, but also allows a sufficient amount of light to pass through.In addition, this material is quite light, but shockproof, which gives an advantage over glass structures. Does not need special care.

- The standard height of 2.5 meters allows you to grow not only low plants.

- Designed for heavy weight.

- Comfortable dimensions (width 2.6 or 3 meters) make it possible to maximize the use of all the space to accommodate two beds and a passage.

Uralochka

The greenhouse "Uralochka", the leading feature of which is the strength of a metal frame with a coating that protects against corrosion, is manufactured by Neftekamsk mechanical plant. Ease of assembly is also a significant advantage.

Other advantages include:

- durability;

- withstands up to 20 kg per m² of precipitation weight (it is important not to forget to take into account the coating weight), which allows the construction to remain intact for the winter;

- reliable sealing;

- simplicity in leaving, does not demand special processing;

- resistance to drops and maintaining the most comfortable temperature inside the greenhouse.

Analyzing user reviews, they point out certain disadvantages.

- For ease of assembly hides a common mistake of installing a greenhouse without using instructions. In this connection, most negative responses occur.

- In the northern regions, due to the snow load, there are frequent cases of pipe bending. Apparently, the designs are not designed for such weather conditions. To avoid such situations, spacers are installed from the beam.

Having examined the above-mentioned advantages and disadvantages of the “Uralochka” greenhouse construction, it can be seen that the drawbacks are minor and easily removable, especially if you use the instructions during installation.

Innovator

Greenhouses "Novator" - a new generation of designs from the Russian manufacturer NPO "Innovation" that meet all international standards. Such models allow you to build harmoniously in the exterior of the building in the best match of price and quality, as well as simplify the process of maintaining the microclimate.

Innovations among greenhouse varieties.

- The automatic built-in system makes it possible to autonomously produce watering of plants and aeration of the greenhouse. This automation allows you to start the season earlier than usual terms.

- Partial "independence" of the greenhouse construction increases the amount of free time that can be given to other types of country work, and even on a banal rest.

- The structure of the greenhouse makes it possible to grow crops even in regions not intended for weather conditions. Reviews suggest that seedlings in such structures grow even faster and more actively.

Characteristic advantages of the Novator greenhouse.

- An extended range of designs and designs that are delivered with a passport and in original packaging.

- Resistance to winds and precipitation due to the dimensions and pitch of a shaped pipe. Uniform distribution of the load is carried out by installing the reference arcs clearly perpendicular to the beams. Arcs are located a meter apart. Therefore, such greenhouses are not afraid of snow in the winter.

- Ensuring tightness with special seals.

- In the design of the greenhouse set on two doors with vents, if necessary, the number of vents can be increased. It is worth noting the presence of built-in locks in the doors.

- The ability to grow plants that need to be hung.

- The greenhouse can be fixed on the ground with special "anchors", while excluding the cost of installing the foundation.

- Ease of installation design, which is noteworthy for beginners.

- The ability to divide the space into sections, if the plants do not transfer the neighborhood with each other. For this, special partitions are provided.

- Polycarbonate coating.

- Free height adjustment for different types of crops.

The cost of one type of construction of the “Novator” type - mini-greenhouses made of polycarbonate “Feeder” without additional configurations and 1.5 meters wide starts from 5,900 rubles.

Tsarskaya

The greenhouse "Tsarskaya" is a series of structures of 5 types of different shapes and characteristics. All types really set without a foundation. Although its presence, of course, will improve the stability and prevent the possible subsidence of the structure.

General characteristics.

- The ease of both the design itself and its installation. Without mounting on a foundation, it is quite simple to move a greenhouse with a couple of people.

- Durability - manufacturers indicate up to 50 years of service with proper care.

- The use of high-alloy steel of austenitic class for the manufacture of the frame increases the possible snow load.

- Variations of the coating design either polycarbonate material or film.

- If necessary, increase the length through special inserts.

- Does not require anti-corrosion treatment.

- Most models for strength are equipped with double arcs.

The “Tsarskaya” group of structures represents certain models.

- "Fairy tale" straight wall shape with a width of 2.5 to 5 m, a height of 2 m and a length of 2 m. A characteristic feature are two ridges, straightness of the walls and a dome roof. Withstands rainfall up to 750 kg / m².

- "Arrow" has a teardrop shape, width from 2.7 to 3.5 m, height 2.4 m, length from 2 m (a multiple of 2). Single and divided arcs in the ridge area. Possible load - up to 650 kg / m².

- "House" arched shape. The widest model - 3 m, a height of 2.1 m, a length of 2 m (again, a multiple of 2). The arcs are single, but solid and fairly durable. The load is less - 450 kg / m².

- "Dream" also arched form with a double arc, thereby increasing the possible load up to 750 kg / m².

- "Star" the same form has a width of 2.5 and 3 m, a height of 2.1 m, a length that is a multiple of 2. Due to the double and whole-curved arc, the load can be up to 450 kg / m².

Also among all other models there are options for smaller and larger designs.These are greenhouses "Tsarskaya Malyutka" and "Tsarskaya ZIL". If the parameters of the first are within 2 m in length and width and it is easy to move, the second one is much more powerful than all of the above. The height of this design can reach 4 m.

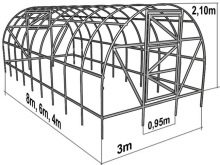

Lider

Greenhouse "Lidep" was developed based on the wishes of gardeners.

What is such a structure:

- the size of the building can vary: 3x12 m, 3x10 m, 3x8 m, 3x6 m, 3x4 m, and a height of 2 m;

- the material for the frame is a profile steel pipe 25x25x1.5 mm and is used cellular polycarbonate with a thickness of 4 or 6 mm;

- it is recommended to install on a foundation of brickwork, concrete, channel or wooden beam;

- in the basic package, you can optionally add upper modular vents or partitions for dividing the frame into two parts;

- in windy weather, special holders are especially practical;

- There are one doorways in the standard equipment for the 3x4 m frame, and two modules for large parameters of the greenhouse.

Contaminants from the surface of the greenhouse are removed solely with a cotton cloth using detergent and water. Otherwise, dry wiping harms the protective coating layer. Detergents in their composition should not contain chlorine, ammonia and caustic alkali.On the damaged area of the coating should be used paint for the car in order to avoid metal corrosion.

The winter is not dismantled if it is known that the snow depth around the structure does not exceed half a meter, and on top of the greenhouse on polycarbonate is no more than 10 cm. Under other conditions, it will be necessary to regularly sweep the snow, otherwise deformation or even destruction of the frame and cover. It is worth remembering that the snow load of the structure is not more than 20 kg / m² with a wind speed of up to 15 m / s.

A significant advantage of greenhouses "Leader" is the possibility of easy transportation.

Largush

Greenhouse "Largush" from the manufacturer "Largo Enterprise" is elementary to install, as it has the optimal amount of parts and does not need to be installed on the foundation.

Other design features:

- the size of the greenhouse - 3x6x2 m or 3x4x2 m;

- durable polymer coating on the steel tube as a frame;

- lack of foundation is compensated by special reliable lugs;

- tightness of all connections;

- the presence of two doors and two windows;

- the use of durable reinforced film for a roof that can withstand temperature fluctuations from -50Сº to + 80Сº;

The cost of a smaller model of greenhouses "Largush" from 7 thousand, more - from 16 thousand rubles.

Orange

Greenhouse "Orange" - easy to install, but at the same time reliable design, in demand for more than 5 years. The shape of the greenhouse is an oblong dome with transverse arcs. Considerable space for growing seedlings is associated with the construction parameters - 4x3, 6x3, 8x3, 10x3 and a height of slightly more than 2 m.

One of the most important points when choosing a greenhouse is the reliability of the frame. The design of "Orange" is distinguished by high-quality bearing coatings of Cherepovets steel with a coating of polycarbonate. The thickness of the zinc layer on the metal is twice that of other manufacturers. The stiffness of the profile gives a closed crimp seam pipe.

The second stiffener is the arched structure on the reverse side of the profile.

A significant feature of the device is the door module, which is a two leaf. At the locations of doors and windows, a special reinforcement is installed to prevent rapid wear.

Polycarbonate coating does not require special care or treatment.

The extension of the greenhouse with inserts of 2 m is possible. The average cost of the “Orange” greenhouse with the smallest polycarbonate starts from 16 thousand rubles.

Eco

Greenhouses "Eco" from the most popular manufacturer "EcoToplitsy" guarantee the most efficient cultivation of environmentally friendly products due to natural light, water, temperature and natural fertilizers. The design feature is the use of special technology without welding seams, which allows you to protect the metal from corrosion.

Other characteristics of Eco greenhouses include:

- long service life (almost 2 times) in comparison with similar structures;

- snow load - up to 450 kg / m²;

- UV protected polycarbonate;

- spacious doorways and vents;

- a combination of acceptable cost with quality;

- easy installation

Advantages and disadvantages

Sharp frosts in spring or autumn, rainy summer, harsh and long winter have a negative effect on plantings. Therefore, an obvious advantage of greenhouse structures is, of course, crop protection from the variability of weather conditions.

In addition, today there is a huge selection of ready-made options for greenhouses, which are elementary in the installation and do not require the participation of specialists. It’s easier, because you don’t have to make the same arcs, accessories, stocks and pipe benders yourself. However, in such facilities there are drawbacks.

Traditionally, greenhouses are arched and covered with polycarbonate. Such a choice of form is not justified by the optimal design, but by the convenience of manufacturing for the manufacturer. To do this, take a sheet of 6 m and bend into the semicircle. Thus, with a width of 3.8 m, the height of the greenhouse is 1.9 m, which is not so much, so often the greenhouse has to be installed on a high base.

The reflective property of polycarbonate affects the loss of necessary sunlight. The arched design in this matter is inferior to greenhouses with flat surfaces that are focused on the perception of light. This form of greenhouse reflects a much larger amount of heat, which is why such structures are characterized by a significant shine in the sun, but in places of glare the necessary amount of light does not fall inside.

Another significant disadvantage of finished polycarbonate greenhouses is full transparency on both sides, as a result of which the heat that comes from the south side simply comes out on the other. In self-made designs, the sun's rays remain inside the greenhouse, heading towards the plants.

Forms

The designs of greenhouses have the following forms:

- single or gable with vertical walls;

- arched;

- polygonal

- greenhouse-pyramid;

- dome

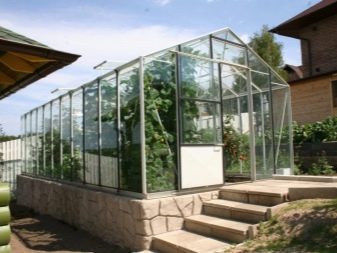

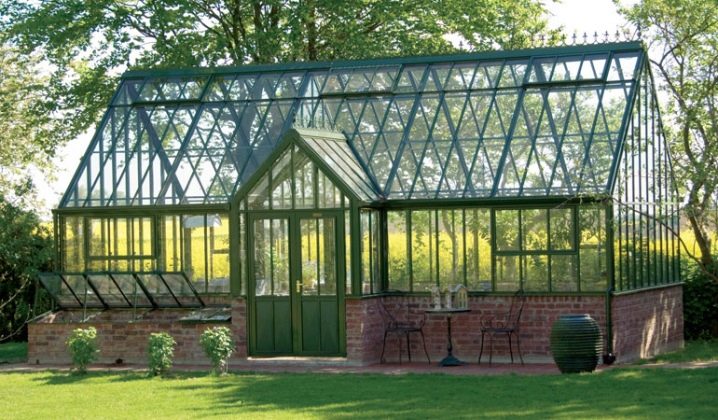

Single and double gable

One of the most common designs are single-slope and double-slope greenhouses. The first can be built right outside the house or any economic structure so that one of the walls of the house and the greenhouse are combined. This form allows you to reduce the cost of the structural frame and insulation, as the bearing wall of the greenhouse, part-time wall of the house, whether it is made of brick, wood and concrete, in any case, allows less heat than film or glass. The disadvantages of the building may be the accumulation of precipitation due to the shape of the structure and reduced lighting. Therefore, when installing it is important to take into account the position of the greenhouse on the sunny side, excluding the option of placement on the north side.It is also common to have a single-sided greenhouse with a removable roof, which allows, if necessary, to remove individual parts of the roof.

An example of a lean-to roof is Ivanov’s vegetarian, which was developed by a school physics teacher. The slope of such a roof is about 20º, and the back wall plays the role of a reflective screen.

Gable greenhouse consists of two vertical and two end wallsconnected by inclined planes. This square or rectangular design is called "house". It is worth noting a significant weight of the possible load on the structure. Also advantages are the ease of installation of the ventilation system and the suitability for growing rather tall plants over the entire area of the greenhouse. As a frame material can be used as a tree, and metal and brick.

The complexity of installation and significant material costs are the main disadvantages of the gable design.

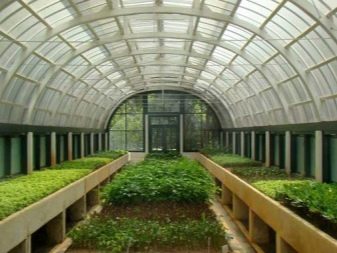

Arched

Arched greenhouse - the most economical option. And the whole thing is in the form of a structure, which dispenses with sharp corners, and therefore the amount of covering material is significantly reduced.Due to this arched greenhouses are famous for their longevity. Also an important feature is the best wind resistance. Most often, such structures are already acquired in finished form, since independent construction is rather laborious.

Disadvantages:

- Possible cracks due to snow load. This form of snow drops down much worse and it often has to be cleaned.

- The limited placement of shelves and racks indoors due to the shape of the structure.

- Difficulty in accessing extreme rows.

One of the varieties of the arched design is a teardrop shape. It is a cross between a gable and arched greenhouses. Due to the connection of the roof slopes at an acute angle, the construction is reliable, and precipitation does not linger on it.

Polygonal

Polygonal (often octahedral) the design is not used as often, despite its significant advantages:

- attractive and spectacular appearance;

- high transparency;

- strength.

The minuses are the complexity of installation and the high costs of both the material and the ventilation system, which will require the development of a drawing.In addition, it is quite difficult to maintain a stable temperature.

The project of such a greenhouse was created to improve the process of dispersion of light in a glass structure.

Pyramid greenhouse

Greenhouse-pyramid is quite rare and, rather, in experimental or design ideas. The originality of the design is combined with the complexity of installation.

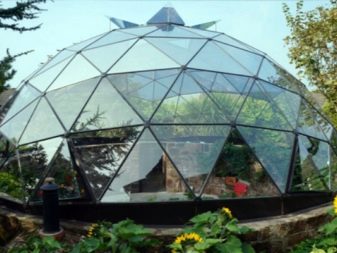

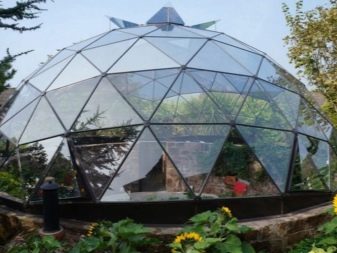

Dome

An innovation is the dome model of the greenhouse. It is a structure with interconnected triangular elements.

In addition to the unusual appearance, the advantages of this model are:

- scatters light much better;

- heat resistant;

- does not need supports and the foundation, as the coating itself is self-supporting;

- wind resistance due to aerodynamic shape and wide base;

- practical arrangement of beds;

- high round greenhouse allows you to be in it in full growth;

- the ability to raise the beds above, which is especially important for elderly gardeners;

- low weight

The intricacy of the installation and the problem of exploiting the entire space are serious drawbacks of the circular design. Reviews say about the difficulties of passage in the greenhouse with a wheelbarrow.

Dimensions

Greenhouse designs come in a variety of shapes and sizes.

Choosing the option for the garden, you should focus on the following items:

- total area of the site;

- what crop will be grown and its maximum height;

- comfortable accommodation in the whole human height;

- purpose of construction: industrial or for personal use;

- available for construction costs.

The parameters of the greenhouse determine 3 values: width, height and length.

The primary indicator is the width. From this value depends both the convenience of those who will work in the greenhouse and the comfort of the plants themselves. Moreover, when calculating it is necessary to take into account the width of the door, the average of which is 57-62 cm. If desired, shelves of 98-108 cm wide can be installed in the greenhouse. It is necessary to take into account the parameters of the passage between the beds, the optimal width of which is not less than 60 cm .

Thus, adding up all the indicators, the minimum width of the greenhouse construction will be:

57 + 98 + 60 = 215 cm

However, experts recommend adding an additional 30 cm to these parameters, which ultimately allows us to derive an average width of 245 cm.

The next indicator - the length of the greenhouse. If the choice fell on a ready-made structure, then the best option would be a length equal to the sheet of polycarbonate, from which the structure is being erected - 200-210 cm. To this parameter 10-15 cm of greenhouse walls are added. When planting plants in racks pallets, it will be more efficient to build a non-long greenhouse to maintain an optimal climate.

The height of the greenhouse depends on how many materials are available, if the construction will be held personally without the involvement of third-party companies. The optimally comfortable parameters are considered a gap of 180-200 cm. In that case, even if the height of the plants themselves is up to 50 cm, in such conditions one does not have to stand, bent over.

It is worth remembering that large structures require significant costs not only for construction, but also for heating. In addition, special enlargers are included in the sets of some already finished greenhouses, if suddenly the design parameters have become too small.

Materials

In order to withstand weather conditions, such as wind, snow, rain and temperature fluctuations, greenhouse frames must be made of very strong material and covered with high-quality coating.

Tree

The first frames were made of wood. Due to its reasonable cost and ease of processing, this material was quite popular. In addition, wooden buildings have a low thermal conductivity. But the essential disadvantages of such structures are the high risk of fire and not a long service life. Although it is possible to use various antiseptics and choose less whimsical wood (larch, spruce, pine, etc.)

Metal

Many positive reviews have metal frames. Galvanized or painted construction will last a long time and is elementary in installation. However, behind these advantages lies a predisposition to corrosion and high thermal conductivity.

Material such as aluminum does not corrode. Ease, durability and strength are second only to high cost and the same thermal conductivity characteristic of metal.

Does not threaten the corrosion of fiberglass reinforcement. The frame of this material is lightweight and requires minimal construction time (depending on the parameters - about an hour). Despite the flexibility of the reinforcement, the structure is reliable and durable.Does not require a foundation.

As a building material, greenhouses choose composite reinforcement with a diameter of from 6 mm to 8 mm.

As a material for coating greenhouses use:

- film;

- glass;

- polycarbonate.

Film

Of course, the most affordable in terms of cost and self-assembly is film. A roll of the greenhouse cover with a length of 100 m and a width of 4 m will cost up to 5,000 rubles.

Among the benefits also note:

- ease and mobility;

- not required foundation;

- skips the optimum amount of UV light.

Unfortunately, this is where pluses end, giving way to rather significant disadvantages:

- the film is unreliable and quickly damaged;

- This material has a negative effect on the cold - after the winter, the greenhouse often has to be wrapped again.

However, if these disadvantages do not frighten, then to cover the greenhouse with polyethylene material will be needed:

- directly film itself;

- reiki;

- screwdriver;

- furniture stapler

Glass

Glass structures are more durable and, on the one hand, stronger than the film, but are subject to both physical stress and temperature difference in the greenhouse itself and beyond. Possible overheating inside the room in the hot season. The minimum glass thickness is 4 mm.And by improving the lighting of the greenhouse due to large frames, heating costs are also increasing. In addition, the transportation of such a fragile coating itself is rather laborious, not to mention the glazing. After all, the load on the weight of the glass must match the parameters of the frame.

Among the positive aspects of this material include:

- optimal thermal insulation;

- high light transmission ability.

A set of 4 mm thick glasses for a construction with an area of 12.6 m², which includes components for windows, doors and partitions, will cost 21 thousand rubles.

Polycarbonate

Today innovative material is polycarbonate. It is a fairly hard, colorless plastic, which can even be melted several times.

Polycarbonate greenhouses have clear advantages over the above coatings:

- it is lightweight and flexible material;

- nice appearance;

- reliability - they are stronger than glass almost 200 times;

- not influenced by temperature and weather conditions;

- fire resistant;

- perfectly keep warm:

- lighter glass 16 times;

- light conductivity up to 86% and light scattering over the entire area of the greenhouse;

- reliable noise insulation;

- durability;

- not subject to physical stress;

- UV protected.

Among the negative qualities, if you can call them that, you can note:

- mandatory installation on the foundation;

- due to the hollow structure, dirt is exposed, causing the light transmission function and appearance to deteriorate;

- with the wrong arrangement of sheets (UV protection inside) reduces the time of operation.

However, taking into account all these features during installation, it is quite possible to do without damage and to operate a polycarbonate greenhouse for a long time.

In the modern market there are several varieties of such material:

- cheaper Chinese products with low quality;

- durable and durable European polycarbonate, differing, of course, and cost.

The price of cellular polycarbonate with a thickness of 4 mm - from 148 rubles per m².

Equipment

Innovative technologies allow today to equip the greenhouse with the latest technology, as much as possible facilitating the work of gardeners. This not only eliminates a lot of trouble, but also increases the yield by 15-30%.

The following systems are involved in creating optimal conditions in the greenhouse:

- heating;

- glaze;

- lighting;

- ventilation.

The fundamental difference between a greenhouse and a greenhouse is the presence of an artificial heating system.

The principle of the heating system can be based on the following options:

- Electrical equipment is a set of electric heater, heater unit and a variety of convection systems. For high efficiency of this method of heating greenhouses hide the high cost of electricity. Therefore, in such cases, to save money, they install autonomous power sources, such as a solar vacuum collector.

- Air equipment is considered a professional installation. This is a standard ventilation system, which is mounted together with the installation of greenhouse construction. In this case, the air enters both the upper and lower parts of the structure, thereby protecting the landings from thermal burns.

- Infrared equipment significantly reduces the cost of electricity, while the heated air masses are distributed as evenly as possible. Mounted such devices around the perimeter of the greenhouse,due to which the heat loss coefficient is reduced.

- Gas equipment is the ideal value for money. With this method of heating a gas generator is used, which delivers the warm air heated inside to a specific section of the structure.

An important and high-quality system of watering the beds.

There are several types of ready-made kits.

- Subsoil watering It is considered the most practical with the possibility of using the well, but this option is very laborious and often does not justify itself. For such a method, an intralunar system is equipped with any water tank, a watering can, a hose and a measuring device. The depth of the system is influenced by the type of culture.

- Drip irrigation provides for the use of pipes and special droppers. It is more expedient to choose pipes polyethylene or polypropylene, although a variant of a metal pipeline is also possible. The basis of the design is a centralized water supply system or a well with the mandatory use of a pump. Often such a system is used for irrigation of beds in open ground.

- Automatic option watering plants most often used in industrial quantities.It is a complex structure of a large number of pipes, hoses, droppers and automatic control of water supply.

- The so-called semi-automatic option irrigation. It is based on the use of plastic bottles. The undoubted advantage of such a system is the minimum cost and short time of arrangement. The standard volume of used bottles is 1-2 liters, on average it lasts for 2-3 days, depending on weather conditions and the needs of plants in moisture.

To install such a system will need:

- directly plastic bottles themselves;

- scissors;

- needle;

- a shred of gauze, cotton cloth or nylon;

- shovel.

The ideal microclimate in the greenhouse design will allow you to create a fogger, regardless of whether artificial or natural ventilation is installed. Moistening occurs due to splashing of water under pressure up to 100 atmospheres. Water particles formed with the help of nozzles that do not exceed 10 microns in diameter hang in the air, thereby creating a fog effect.

Such systems have an advantage over standard irrigation systems in that they are ideal for sensitive crops, improving seed germination and stimulating growth.In addition, performance is ensured regardless of the time of year.

Pluses fogger:

- minimization of the cost of water and electricity;

- improving the performance of greenhouse construction;

- maintaining an optimal level of humidity;

- accelerating plant growth;

- reducing the need for watering;

- stable microclimate;

- minimizes human performance.

Light plays a key role in growing plants. That is why the construction of greenhouses are chosen places the most illuminated. However, even with an ideal location to improve the harvest can not do without a system of artificial lighting. This is especially true for areas where there is a short light day.

The material filling the lack of light, are several devices.

- Standard incandescent bulbs are allowed only when growing greenhouse greens and are strictly forbidden to seedlings of cucumbers and tomatoes. It's all about the infrared type of radiation, which is dangerous deformation and even burns during prolonged interaction with plants. The recommended usage time is no more than 15 hours.

- Significant heat and a time limit of use are mercury lamps. In addition, a large amount of ultraviolet radiation is emitted in the near propagation spectrum.

- The most common for greenhouses fluorescent lighting. They are famous for economy and long-term use. True, the parameters of heat transfer are not acceptable enough.

- Competitive sodium lamps compensate for the lack of heat transfer. Their yellow-orange monochromatic light field has a beneficial effect on the development of planted plants in the greenhouse. Enough economical option.

- One of the most expensive options is LED lighting. Opinions about the arrangement of such devices in the greenhouse are very different, because of the directivity of the radiation requires a lot of points of illumination.

- The best option are metal halide lamps. With its durability, they are quite small. In addition, their significant plus is in terms of natural light.

It is obvious that for complete air exchange in a greenhouse it is not enough just to install several air vents, especially if the design is rather large.It is desirable arrangement of a forced ventilation system. The hydraulic cylinder will automate the process of ventilation.

To install you will need:

- air vents from all ends of the greenhouse and on the roof;

- openings on the top for ventilation;

- special sensors;

- automatic control panel;

- circulation fans.

The system will maintain the optimum temperature., if necessary, opens and closes the vents, will ensure the circulation of fresh air. The principle of operation is based on the movement of the piston due to the expansion of the liquid when exposed to heat. With decreasing temperature, the hydraulic cylinder is activated by the initial position of the fluid, closing the vent. Of course, the cost of such a device is great, but these costs are quite reasonable.

As the fluid in the hydraulic cylinder suitable automotive oil or flushing composition.

Manufacturers

Even at first glance, there is a noticeable contrast between the domestic construction of the greenhouse, produced at the plant, and the Chinese attempt at plagiarism. The poor quality of the greenhouse is very thin and easily bendable.

To select quality products, we present you a rating of popular modern Russian manufacturers.

Volia is a company from the city of Dubna.Reviews indicate such high-quality models as Dachnaya-Strelka, Dvushka and Optima. Branches are located in Moscow, St. Petersburg, Nizhny Novgorod, Saratov, Samara, Sverdlovsk regions.

Reliable design is offered by the manufacturer from the capital "New forms". The current popular collection of models is represented by the models “Bogatyr”, “Fairy Tale”, “Kremlin Suite” and “Star”.

Manufacturer from Nizhny Novgorod TD "Harvest" is known throughout Russia. The best models are “Crop-PC” and “Crop of Elite Absolute”.

Neftekamsk plant is famous for the quality and reliability of the Uralochka greenhouse structures. Branches of the manufacturer are represented in most of the largest cities in Russia.

Tips for choosing

When selecting a greenhouse, attention should be paid not only to the manufacturer, but also to some factors.

- It is worth deciding on that, to build the greenhouse independently or to choose already ready models. Given the advantage of the second option, it is important to check the configuration of the structure. It should include not only the frame and coating material, but also seals, doors and vents.

- Decide what goals are pursued in the construction of such a building: it will be the production volume of growing flowers or a simple household for the cultivation of fresh fruits and vegetables, since the size and even the shape of the greenhouse depends on it. For example, the best floral designs are built with sloping roofs and with a lower south side.

- The next step is to determine which plants will be in the beds, given the fact that not all cultures can get along with each other. Thus, the beds of pepper and cucumbers will be comfortable side by side, but planting next to the tomatoes is undesirable next to the tomatoes.

- Next, pay attention to the choice of material to cover the frame. In addition, the foundation cannot be ignored, although the base of the greenhouse is not necessary in all cases.

- And, of course, you need to decide what functionality the future design will have - the ventilation system, automatic watering and heating.

How to assemble yourself?

Manual installation of greenhouses with their own hands is quite simple:

- clearing space for the foundation and installation of wooden ties;

- installation of the base;

- the creation of the frame must start from the front side;

- frames of doors and windows are installed on the hinges;

- end elements are equipped with holes in 30-40 cm;

- the trim also starts from the front side - the polycarbonate sheet is set so that the edge is flush with the left vertical stand of the end face. A self-tapping screw with a rubberized cap is used for fastening;

- Do not forget about the arrangement of vents for ventilation, which are often located in the door;

- fitting installation;

- collection of the second end of the greenhouse;

- installation of arcs for jumpers, measuring for them a place from the middle of the arc in steps of 90 cm;

- placing the cross elements on the arc and mounting the latter with jumpers;

- fastener ends to the greenhouse box T-shaped elements;

- then you need to make holes in arcs every 40 cm;

- covering other parts of the greenhouse.

Successful options

- A typical example of a polycarbonate greenhouse design.

- Unusual multi-level slopes brightly fit into the exterior of the site.

- Beautiful options with transparent polycarbonate.

- Teardrop greenhouse model.

- The frames from the window frames look extraordinary.

- The most comfortable to work model with a sliding roof.

- Large-scale year-round buildings.

- New industrial developments.

- Mobile greenhouse.

- Attached version shedding.

- The original design solution dome greenhouses.

- One of the unusual materials for the construction of greenhouses - plastic bottles.

On the features of polycarbonate greenhouses, and how to choose the best greenhouse, see below.