Features of the manufacture of greenhouses from metal profiles

Greenhouses can be made of various materials: wood, PVC, metal, but the manufacture of greenhouses from metal profiles has its own specific features. Before proceeding to its construction, it will be necessary to study some theoretical foundations. This in the future will greatly facilitate construction work.

Features and types

Many gardeners who prefer to do everything with their own hands, prefer homemade greenhouses. Despite the fact that completely different materials can be used for this, the construction of a greenhouse made of metal profiles is the simplest. Such a construction, built by hand, will not yield to purchase either in appearance or in functionality.However, it should be borne in mind that its construction will take a lot of time and require a decent amount of strength.

Immediately you should make a reservation what to do the greenhouse itself is not always a good idea., because many are faced with the inability to buy cheap and high-quality material. So before you decide, you need to carefully calculate everything and find out which of the options is more rational - purchased or self-made.

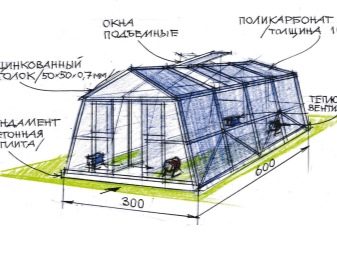

Without dwelling here on the types of existing structures, it is worth pointing out the most successful solutions that help fight the winter Russian realities. So, now it is often possible to meet greenhouses with a folding or with a reinforced roof instead of ordinary ones.

With collapsible roof

Removable roof - a bad option for those greenhouses that are operated throughout the year. But this solution is perfect in cases where the greenhouse is seasonal, for example, country house. Removing the roof ensures the absence of a strong load on the profiles, and if necessary, the roof can be returned, the soil inside cleaned. After that you can reuse the greenhouse.

A collapsible roof may not be built from every cladding material., but only from light and durable, so that there is no risk of damaging it during dismantling. Also, when choosing a greenhouse with a roof of this type, immediately consider whether you will also dismantle the walls for the winter. This is done in cases where the site is located in a windy area and there is a possibility that during bad weather the entire greenhouse system may simply be blown off.

This option will require additional labor costs for the annual removal and installation of the roof, as well as the care of an open profile frame.

With reinforced roof

In cases where the ability to build a structure with a removable roof is not, resort to strengthening the frame. The reasons for this may be many. The need for year-round use of the greenhouse and the increased risk of destruction due to wind are just some of them.

Amplification is done in two steps. First, the step between farms is reduced. This is the name of each cross-sectional "layer" of the frame that encircles the walls and roof. Secondly, in the process of mounting additional elements are attached: strut, reinforcing the rack.For fastening all the elements used heavy-duty methods, for example, welding.

The construction of a reinforced structure can be financially the same as the purchase of a finished greenhouse. A predetermined calculation will help to determine whether to make a profile or it is better to immediately buy ready.

Types of construction

Total greenhouse structures from metal profiles are represented by countless. Not all of them are suitable for building their own. For example, complex semicircular extensions, greenhouses resembling a needle are the homes of northern residents, rounded greenhouses require remarkable experience, as well as the presence of profiles of the desired shape. Despite the fact that each of them is convenient and has a large amount of usable space, they are only available for purchase in finished form.

Another problem is the simplicity of the design with insufficient functional qualities. For example, greenhouses of the type of dugout, only a meter higher, are very easy to build, but there will be too little space inside, and the gardener will have nowhere to turn.

In practice, the most common are four types of buildings that you can do yourself, while they will be comfortable, fully meeting the requirements for light and usable area.

By mitlider

Greenhouses of this type can be both arched and gable. The difference from conventional roofs here is in the arrangement of the slopes: one of them is placed slightly higher than the other, and the remaining gap adapts to the vents. Thus, greenhouses according to Mitlayder are the best option in terms of ventilation, air circulation inside.

However, not everything is so simple. Such a greenhouse can not be equipped with a dismountable roof, so it is not suitable for snowy areas. Strengthening the frame here will be much more difficult because of the special design of the roof, so not only careful planning is needed, but also some engineering knowledge. In short, if there is such an opportunity, it is best to entrust the design and construction of this type of greenhouse to professionals or to buy ready-made. If you are confident in your abilities, you can try to calculate everything yourself.

Single bar

Most often, greenhouses with a single-pitch roof are used as an extension to the garage, house, bath and other sturdy and stable structures. Such designs are not only simple, but also comfortable. There is a lot of space in them, except for this,You can save a lot of money on heating.

If you fit the greenhouse close to the wall, then part of the heat from the house will be transferred to the greenhouse.

There are a number of specific requirements that are inherent in lean-to designs.and the first one is its location relative to the main building. It is important that the greenhouse is not in the shade, otherwise it will not be possible to grow light-loving plants in it. This means that we will have to abandon the lion’s share of the usual crops: cucumbers, tomatoes, bell peppers, onions, and fruits - grapes, strawberries and others. The optimal location of the adjacent greenhouse - on the south side of the facade.

Gable

Gabled detached houses, greenhouses can be found in many private areas. This is due to the fact that they often fit perfectly into the surrounding space due to their classic appearance. This especially applies to situations where the house itself is also equipped with a gable roof.

Such greenhouses have many advantages. First, they can both be strengthened and equipped with a removable roof. The second option is not needed if the greenhouse will have high slopes: the snow will simply slide off from them. Secondly, it is easy to build such a greenhouse due to the fact that it has an intuitive structure.You can also make a drawing yourself without preliminary preparation. Thirdly, the greenhouse itself turns out to be spacious. Even in a small area, you can fit a maximum of crops.

Arched

The arched type is the most common of all, and the arches can be erected both from straight parts of the profile and with the help of a special arched element. The difference will be noticeable only near.

Arched greenhouses have all the same positive properties., as duo-pitch, however, it is necessary to struggle with the fact that they can subside under the weight of snow - no high slope will save them.

Another advantage of arched greenhouses is good air circulation in them due to the domed roof.

Whatever type of construction you choose, remember that the guarantee of their long service is high-quality materials and proper installation. Only in this case, the greenhouse of the metal profile will be quite strong. Otherwise, no matter how hard you try, the whole structure will quickly become unusable due to some minor flaws.

Advantages and disadvantages

A greenhouse built using profiles has its advantages and disadvantages.

Positive aspects include several aspects.

- Financial component. Due to independent construction, it is often possible to save considerable money, moreover, the quality of the greenhouse will be at a sufficiently high level.

- Independent choice of shape and size. Along the way, you will be able to adjust both, and you only need to purchase the missing parts, and not order a new greenhouse, as is the case with the purchased one.

- Long service life. For the production of profiles using galvanized steel, which is not amenable to corrosive changes. Therefore, such profiles will not rust due to humidity, and the greenhouse will last for a long time.

- Low weight. Due to this, the entire structure can be erected alone, and later rearranged on the site, if you built a mobile greenhouse.

- Ease of installation. For the construction does not need special knowledge and skills.

The shortcomings of homemade metal greenhouses are not so numerous. In fact, the disadvantage is only one, and it lies in the fact that the frame can not withstand the snow mass, but greenhouses with a removable roof or a reinforced frame are being made to solve this.

The choice of profile and shape design

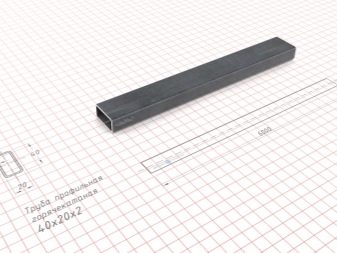

Basically, for the construction of greenhouses used profiles for drywall. They are represented on the market in a large variety both in terms of strength characteristics and dimensions: width, height, length, thickness of steel. It is worth noting that not every profile is suitable for construction. The most frequently used square shaped structures with a cross section of 20-40 mm and with a steel thickness of 1 mm. For these purposes, suitable only bearing ceiling or wall profiles.

You can find a specialized profile zigzag for the greenhouse. It is needed in order to secure the film. A zigzag bar inside the profile bar is called a clip. So, the film is clamped between the end part of the profile and the adjacent side of the clips, as a result of which it is firmly fixed.

Plating materials

To cover the greenhouses of metal profiles is used not only film. There is also a mass of materials with good light transmitting ability and excellent heat-saving indicators. Fastening them is somewhat more difficult, and care is required a little different. It is worth considering each of the cladding materials in more detail.

Film

Everyone is familiar with classic greenhouses covered with thick PVC film. This option has both its advantages and disadvantages. On the one hand, the film is easy to attach and, if necessary, dismantle. It is almost completely transparent, with the result that such a coating ensures sufficient penetration of sunlight into the greenhouse. The film is excellent heat insulating, and the heat does not go outside. On the other hand, the film coating can not be compared in strength with the rest. When pressed hard, it will break.

Nevertheless, the film is used more often than other materials also due to its low cost. After all, you can use not only a special film, but also one that is already available on the farm. For example, a protective film could remain after the delivery of furniture or other large items. Few people are stopped by the fact that this material does not decompose at all, but from an environmental point of view it is unsafe.

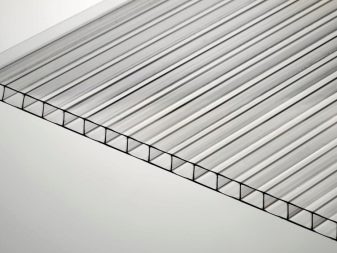

Polycarbonate

Polycarbonate panels were used not so long ago in greenhouse construction. This material well passes light, and also does not let out heat.Two types of polycarbonate are produced: monolithic and cellular. Monolithic for greenhouses is not suitable because of the cost, and a cheaper cellular option can be used.

At the joints, the material must be carefully sealed to prevent heat loss. At the same time, the lower edges should be left open so that the material “breathes”. The hard-hitting truth is that polycarbonate cannot be bent, so its installation is possible only on flat frame surfaces. To cut the polycarbonate sheets, also have to use special tools. Otherwise, the material will simply crack and become unusable.

Double glazing

The use of glass - a new practice in the construction of greenhouses. Double-glazed windows have several advantages. For example, they can not be broken: the glass just goes cracks, and fragments do not fly around. This makes the material great for those cases if children often play on the plot with a greenhouse. Accidental hit of the sword is not terrible here, and in the event that fragments do not arise, so the kids will not be able to cut themselves.

Double-glazed windows have high heat-saving characteristics. Thus, they are an excellent solution for regions with harsh winter conditions. From this we can conclude that the double-glazed windows make great winter greenhouses. Many double-glazed windows have the function of protection against harmful infrared radiation, passing only the rays of the "useful" range. There are special anti-vandal models with increased strength.

Glass

Glass greenhouses are gradually becoming a thing of the past due to the low performance properties of glass as a material. It is very fragile, so any mechanical impact can have fatal consequences. However, glass has one advantage, which allows you to close your eyes to all the existing shortcomings: it perfectly lets in sunlight, as a result of which the temperature in the greenhouse is several degrees higher than in similar ones of the same area from other materials.

Another drawback of glass, due to which many refuse it - is expensive. Some enterprising summer residents found a solution to the problem.They collect unnecessary window frames with glass inserts and use them as parts for the greenhouse. It turns out like a shield design. Wooden frames are conveniently mounted to metal profiles, but it is worth bearing in mind that they have an impressive weight, so the frame should be strengthened. For example, you can make it out of dual profiles.

Plexiglass

Unlike other given materials, plexiglass can be bent, giving it the shape of an arc, and the bent sheet will not lose its strength characteristics. The thickness of the plexiglass ranges from 5-15 mm. This indicates that it will be easy to fix it on the metal profile frame with the help of ordinary self-tapping screws “bugs”.

The plexiglass light transmittance is at a high level, and the thinner it is, the more light it can transmit. However, in the case of durability, everything works in the opposite direction: the thicker the plexiglass, the stronger it is.

Plexiglas differs in small weight therefore with its help it is easy to sheathe the greenhouse on the profile frame.

For year-round plexiglass greenhouse will require additional heating. It is best to take it to the foundation so that it is possible to dismantle the old structure and build a new one without doing the heating anew.

Fastener

For attachment of profiles to each other and for subsequent fastening of cladding material to the frame, various devices are used. It is worthwhile to dwell on them in more detail, since together with the profiles you will need to buy the corresponding accessories.

For fastening parts together need metal screws. Be sure to need exactly screws drilling or self-cutting type. Others will not be able to cut through the metal. Suitable models 4,2x16 mm. "Bugs" should not choose, it is better to give preference to models with a flat cap: they do not begin to interfere with time.

For attaching sheets of polycarbonate, plexiglass or other relatively hard coatings screws will be useful. First, you will need to drill holes, and then screw the screws.

To fix the film, you will need a zigzag profile.

Before you start building, you need to stock up the following tools.

It includes several components.

- Grinder for cutting profiles. It is not recommended to use it, as it can damage the galvanized cover, which will further lead to corrosion.

- Cold galvanized. Sold in cans. It is used after work as a grinder or on welding seams.

- Scissors for metal. Need for cutting soft profiles.

- Screwdriver. Facilitates work with screws.

- Laser level, plumb. They will help to build the frame correctly relative to the ground.

- Construction Roulette. Need for taking measurements.

As for additional materials, you will need quite a bit:

- screws, dowels, bolts for fastening;

- flooring material in the right quantity.

Design and preparation

First you need to decide what your greenhouse will look like. It is necessary to prepare a fully verified drawing, indicating all dimensions. This can be done on paper or in a computer program for 3D-modeling, as well as order an individual plan from a specialized company.

In addition, you need to prepare the site. To do this, it is cleared of debris, the turf is completely removed from it. This is done to make it easier to lay the foundation.It will also be easier in the future to grow greenhouse crops on such ground.

Treat the profiles with an additional anti-corrosion agent to ensure that after some time they will not rust, despite the galvanized coating.

Foundation construction

The difficult base for the greenhouse is not necessary. In fact, you can use already existing from under the barn or summer shower. The task of the foundation for the greenhouse is to prevent it from flying away.

Since the base should not be rugged, the usual tape will do.

- First, dig a trench slightly wider than the future construction. The width of the trench itself is equal to the width of the shovel.

- Then it is compacted with a pillow of gravel and sand.

- Then the crate is put and the concrete solution is poured. To concrete gained strength, you need 30 days. At this time, it is better to protect it with polyethylene from possible precipitation.

- After 30 days the crate is removed, the base is treated with water-repellent agents, for example, bitumen.

After that, the foundation can be considered ready.

Frame assembly and trim

The assembly of the frame is carried out in accordance with the existing project.It is important that the step between the profiles is adjusted in accordance with the skin material: the heavier it is, the smaller the distance between the profiles. For example, for polycarbonate plating, you need to weld profiles at a distance of no more than 70 cm from each other.

Step by step assembly instructions frame.

- The assembly starts from the back. First, perimeter ends are erected: the roof and the side parts. Further, all intermediate metal profiles are mounted.

- After that, an end is made from the front side.

- Further between them the profile designating the middle of a roof is pulled.

- Then the “layer” is located in the middle.

- So, in turn, all the layers are made, which are in the middle between two adjacent ones, until the crate is finished.

Everything can be fastened either with screws or welding.

The cladding material is either attached with screws or on a zigzag profile, if we are talking about a film.

Tips

To choose high-quality profiles and in the future do not regret pay attention to the following points.

- The thickness of the steel must comply with the stated. Use a vernier caliper to measure. Remember that you will not fit profiles with a thickness of less than 1 mm.

- The presence of rust or burrs is unacceptable.

- Profiles must be smooth. Check it out by looking at them along.

How to collect a greenhouse from polycarbonate, see the following video.