Polypropylene greenhouse: step-by-step instructions for making

A greenhouse made of propylene pipes is the easiest greenhouse for self-erecting. The design is presented in several versions. In order to build such a greenhouse with your own hands, you need to follow simple step-by-step instructions for manufacturing.

Special features

A greenhouse made of polypropylene pipes is an interesting solution with a limited budget and a love for building various structures with your own hands. Purchase of materials will not require large financial expenditures, and construction will require serious preparation.

All materials can be purchased at an ordinary hardware store; you will need ordinary glue or screws to fasten them together.

For a start, it is worthwhile to dwell on what the propylene pipes are and how they differ from PVC. In fact, there is no big difference between these materials. And some, and other pipes are plastic. The only difference is what polymer they are made from - polypropylene or polyvinyl chloride. This does not affect the operational properties of pipes, the only noticeable difference is in price.

Polypropylene pipes have a number of advantages.

- Resistance to corrosive processes. Plastic pipes are not subject to rotting or rusting, unlike products from other materials.

- Ease of operation. Pipes made of polypropylene are easy to bend or cut. From them you can create any intricate frame. In addition, to fasten profiles to each other and install them in the ground is also quite simple.

- Low weight. Polypropylene pipes weigh little whether they are single-layered or multi-layered. This is a guarantee that it will be easy to move the whole frame, and not only in a disassembled form.

- Long service life. Initially, pipes made of polypropylene are designed for communications, in particular water supply, so they are given increased strength.Without being subjected to such loads, pipes can last 30–50 years.

- Strength. In addition to resistance to corrosion, such pipes are resistant to temperature extremes. They do not burn, open fire in general they are not afraid. In addition, the frame of the pipes will be able to withstand strong wind, especially if the base is made reinforced. So, the material is not amenable to deformation under the influence of various climatic factors.

- Cheapness Plastic polypropylene pipes belong to the economy segment, so very little money can be spent on the purchase of this material.

- Attractive appearance. It is not necessary to process additional pipes from propylene. They are immediately supplied with a special coating, which not only enhances their strength properties, but also gives the raw material a beautiful shine. As a result, the whole greenhouse on this frame will look great.

Design options

It is possible to assemble a construction of almost any complexity from polypropylene pipes. Restrictions are imposed only by the degree of skill of the one who performs the structures.

The most common forms of homemade greenhouses are:

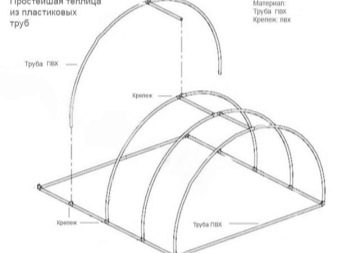

- arch;

- pointed arch;

- with a lean-to roof;

- with a gable roof.

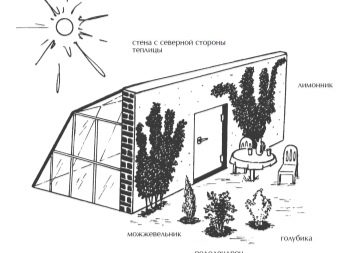

Separately, it is worth noting that greenhouses with a shed roof are usually performed as an extension to the house. Here it is envisaged that one wall will be adjacent. This saves a significant amount of money on heating.

The most simple for the construction of an arched structure. There are some designs that can be put in just a few hours. However, it is extremely important, from what material, and how to be tied. After all, the bars form a strong pressure. In addition, such a construction of polypropylene will not make winter. The pressure of snow on the roof will be too strong, and the frame simply will not stand - collapse.

In this case, use the form of lancet arch. It represents something between a classical arch and dvukhskatny designs. Of course, it requires more details and skills, but the result is beyond all praise. The durable plastic frame is able to stand not for 3-4 seasons, as usual, but all ten.

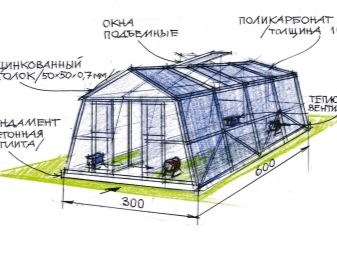

Finally, the dvukhskatny "house for plants" - this is a common option due to its classic shape.This greenhouse will fit into any landscape, suitable for almost any home. To build it, you don't need to be a engineering genius.

This design is the most durable, because the frame is reinforced here.

Rules of work with the material

First you need to learn the nuances of working with pipes made of polypropylene. Only then can you proceed to their installation, the collection of the frame, the laying of the coating material. So, first you need to consider that working with such pipes is best at a temperature of + 18–20 degrees. Then the material will gain maximum strength and flexibility, it will not “shrink”, and it will be easier to form the necessary shapes from it.

The second feature is the need to select fittings for the diameter of an existing pipe. Fittings are connecting elements. With their help, you can achieve optimal rigid bond parts with each other. In order for the work to go as smoothly as possible, it is best to purchase pipes already complete with fittings. So you can eliminate the risk that the connecting elements and pipes do not fit together.

To work with polypropylene pipes may require welding. Many do not have a plastic welding machine on hand. Then there is an alternative - it is a gas burner. It can replace the iron, which is commonly used for welding. However, you need to act carefully so as not to melt the pipes too much. It should be borne in mind that welding is used only in cases where it is planned to build a capital structure out of pipes, which is not planned to be rearranged or removed for the winter. An example is the attached greenhouse with a lean-to roof.

Fortunately, the adoption of any specific protective measures during the work with polypropylene is not required, since the material is not toxic.

The only thing is that polishing may be required at the place of the cut, but this rule is not necessary to observe.

Coating Materials

Covering greenhouses from plastic pipes is a special topic. The fact is that the frame, although relatively durable, cannot withstand the severity of the materials traditionally used for shelter. Plexiglas, double-glazed windows and some others concern to them. Such materials guarantee high protection from drafts, good heat retention even in the winter period, full access to sunlight, but because of their great weight they have to be discarded.

For materials to cover the frame of polypropylene pipes put forward certain requirements.

- High thermal insulation properties. This is especially important if the greenhouse is planned to be year-round, working and in winter;

- Good ability to transmit sunlight. An additional feature of the material may be that it filters out harmful infrared radiation, passing only those rays that are useful for plants;

- Resistance to atmospheric phenomena. It is important that rain, snow or hail could not damage the coating material, otherwise the tightness in the greenhouse will be broken and the heat will come out. Thus, both the greenhouse and the crop will be irrevocably damaged;

- If the greenhouse is year-round, then the cover material must withstand the snow, not to tear under the snow cap;

- Resistance to mechanical and wind loads is desirable. A gust of wind should not damage the integrity of the coating, as well as minor mechanical effects. Some materials are able to withstand heavy loads, for example, shocks, and at the same time do not tear or break;

- Low weight.

Thus, the existing list of materials for coating is sharply reduced, because very few materials combine all the listed qualities.

Optimal for frames made of polypropylene pipes are coated with polyethylene film or polycarbonate plates.

Polyethylene film

Polyethylene film is one of the most popular materials for coating frames made of polypropylene pipes. This is due to its many advantages.

- Low weight. First of all, you should pay attention to the lightness of the film coating. With a sufficiently large area, a sheet of film can weigh only a few grams. This ensures that the frame will have a minimum load.

- Light transmittance. The films are produced either completely transparent or slightly dull, but this does not prevent the sunlight from penetrating well through them, illuminating the entire area. You can vary the amount of light penetrating the greenhouse by simply choosing a film with the desired degree of tinting. This allows you to grow in these greenhouses any crops - and shade-loving and light-loving.

- Resistance to atmospheric phenomena. The films do not respond to changes in ambient temperature from -50 to +60 degrees. They are not afraid of rain, hail, snow and wind. But they will not keep the snow cap.

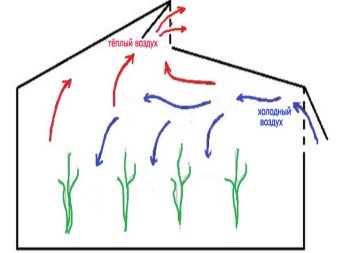

- Creating a greenhouse effect. The air in the film greenhouses is always humid and warm, so the earth does not cool in them either. This allows you to create in such greenhouses the most favorable microclimate.

- Material safety. Polyethylene does not decompose and does not affect the soil, therefore does not change its composition. It also does not release hazardous substances into the air. It turns out that the presence of polyethylene does not affect the content of the greenhouse.

- Cheapness The film can be bought for a low price or even get it for free. She may even be already in the household.

Among other things, has the material and its shortcomings. The film is poorly resistant to mechanical damage. Any puncture or blow is able to break it, making it unusable. It should be borne in mind that such holes are easily repaired with ordinary scotch tape. The film quickly fails, thinning due to the constant exposure to the sun. Such coverage will last only 2-3 seasons.

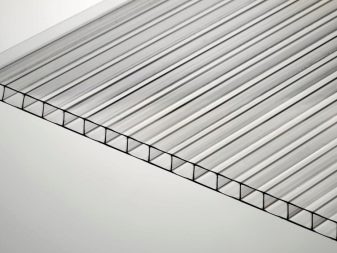

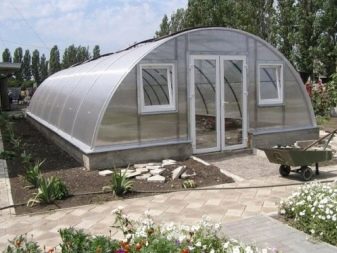

Polycarbonate

Another alternative greenhouse coating material is polycarbonate. It is somewhat heavier than the film, so it will be necessary to compact the frame by using composite reinforcement and additional supports.This material has such advantages that more than justify any inconvenience.

- Good light transmission. Cellular carbonate, which is commonly used for greenhouses, is a stronger alternative to glass. You can choose either completely transparent materials, either matte or colored.

- Strength. Polycarbonate is resistant to any mechanical stress, be it heavy rainfall, shock, puncture. He also does not bend under the weight of snow lying on the roof. Water and high humidity are not scary to polycarbonate, since it is not subject to corrosion or deformation under the influence of water.

- Plastic. Subject to all rules, polycarbonate plates can be bent, giving them an arcuate shape. However, it will not be possible to construct intricate structures: the material is still not so flexible.

- Long service life. According to the manufacturers, polycarbonate plates do not lose their properties during 20 years of service.

- An interesting look. If the greenhouse of the film is trivial and there is almost all, then the polycarbonate separates the owner from the gray mass. Greenhouse looks neat and unusual.

Like the film, polycarbonate has its drawbacks. This material is afraid of high temperatures. When exposed to open fire, it begins to melt, and stop this process is not very simple. Also the price factor plays a big role.

Polycarbonate models are more expensive than film ones, but still not enough to immediately eliminate this option.

Master class in construction

To make a greenhouse from polypropylene pipes is not as difficult as it seems at first glance. In fact, even a teenager who attended labor classes at school will be able to cope with this.

Before you begin, it is necessary to carry out preliminary work.

- A greenhouse, like any structure, will have to be carefully planned and designed. Without a plan and drawings, it will not be possible to build a really good greenhouse, having the correct dimensions and proportions. The scheme can be made independently, ready-made or ordered, but the latter option is not very rational, since an individual sketch will cost more than the entire purchase of materials.

- It is necessary to immediately prepare all the necessary materials and tools.For this, a plan was drawn up: it reflects the location of all profiles and parts, all screws and screws, as well as the fixing point of the cladding material. Having such information in hand, you can buy everything you need.

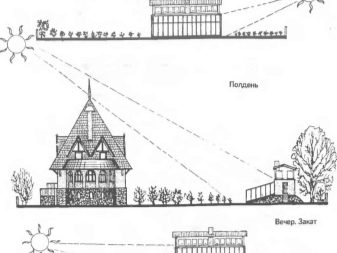

Preparation must be thorough. The quality and speed of the greenhouse construction in the future depends on how conscientiously it is carried out. Careful preliminary work allows you to design a more serious structure, which has not only a door, but also air vents for ventilation. Also, a scrupulous elaboration of details is needed when the greenhouse is not made for seasonal use, but for year-round cultivation of vegetables and berries. Only then it turns out to provide all the nuances, including the correct position of the greenhouse relative to the cardinal points.

Layout

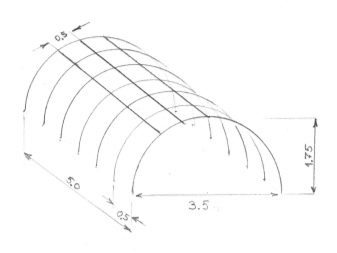

At the first stage, you need to decide what size the greenhouse will be. It depends not only on the needs, but also on the size of the lot. For example, on an area of 100 square meters. m, you can easily fit a large greenhouse, while for a small area suitable only mini-greenhouse.However, it is worth remembering that pipes made of polypropylene are still a material that was not originally intended for construction, so you should not make extra-large structures, for example, 8 m wide and 15 m long. For such purposes, it is better to choose a less flexible material.

The optimal solution is a greenhouse with dimensions of 2.5x4 m and a height of 1.9 to 2 m. You should not do it below, since it will be impossible for a person to straighten there, which will greatly complicate the work on caring for growing crops. Such dimensions will allow to plant in the greenhouse several beds of different crops.

For the construction you need to choose the right cross-section of polypropylene profiles. For this, multilayer pipes with a diameter of 20–32 mm are suitable, the internal cross section of which is 16 mm.

The length of polypropylene pipes can vary, but for the construction of a greenhouse, options from 2 to 7 m are needed.

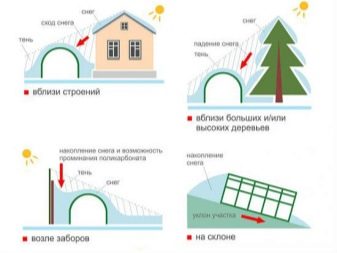

As for the choice of the site for construction, it must meet several requirements.

- No shadow You should not put a greenhouse in the shadow zone, otherwise you will have to abandon the cultivation of light-loving crops: peppers, cucumbers, tomatoes.

- The ability to freely enter and exit the greenhouse.You should not have the door so that it rested tightly against the flower bed or other beds. Need to leave a small space for convenience.

- The site should not be windy. Inquiries should be made as to how the winds blow in your region and arrange the structure in accordance with this direction. This is especially true of greenhouses with pitched roofs.

Drawing Design

The drawing is needed not only to know exactly how the greenhouse will be located and what will be needed for it. The project is important for budgeting, because knowing the number of elements and their cost, you can quite accurately determine the price for the entire homemade greenhouse.

Location map can be made independently, remembering drawing lessons from the school curriculum. To simplify this process, there are many programs on 3D-modeling, some of which are free. Some can be used directly online.

The easiest way is to take a ready-made drawing. In the same place, as a rule, the calculation of parts, connecting elements and materials for coating is provided.It is possible to choose a greenhouse of any size and with any height, including those whose frame requires reinforcement through reinforcement.

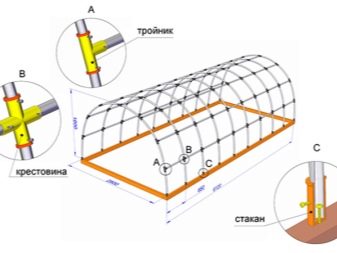

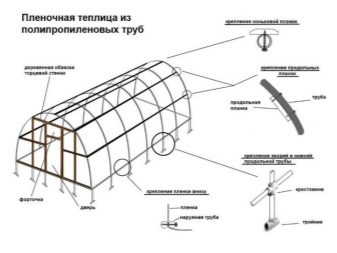

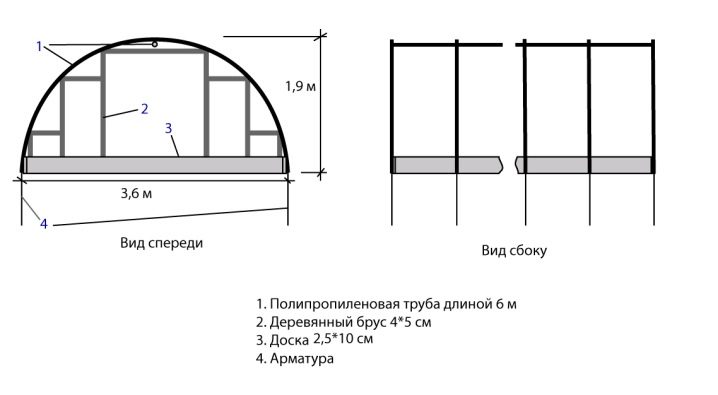

Next will be considered a drawing of a greenhouse film 3.6 m wide, 1.9 m high and 10 m long. The diagram is presented in the following figure:

As can be seen, here the greatest difficulty will be the compilation of the batten for the end part, since many elements are envisaged. It can be seen in the drawing that a foundation is not provided for such a greenhouse, but there is a wooden screed to the bottom, which makes it possible to better fix the structure on the ground.

It is worth noting that the ends of greenhouses with a polypropylene frame are also often made with wooden beams, and this case is no exception.

Preparation of all necessary

First, you must prepare the materials from which the greenhouse will be built.

These include:

- pipe with a diameter of 20 mm and a length of 10 m;

- 15 pipes with a diameter of 20 mm and a length of 6 m;

- 34 composite reinforcement with a diameter of 18 mm and a length of 75 cm;

- polyethylene heat-retaining film for greenhouses 6.5 x 15 m (a reinforced version with a thickness of 0.5–1 mm is ideal);

- wood screws 35 mm long;

- wood screws 50 mm long;

- fixtures for fixing pipe overlaps. Special plastic ties can be used;

- 28 wooden slats 10x20 mm, length 3.6 m;

- 2 boards for screed with a section of 100x20 mm, length 3.6 m;

- 2 boards for screed 100x20 mm, length 10 m;

- 3 m mounting tape.

Parts for the end frame must be purchased separately. Here you will need wooden slats with a section of 30x40 cm or 40x50 cm. They will be needed in a certain quantity and a certain length:

Length, cm | Quantity, pieces |

45 | 2 |

60 | 4 |

123 | 2 |

140 | 2 |

170 | 2 |

360 | 2 |

Also here will be needed screws for wood length 50 mm.

The work will need the following tools:

- a hacksaw for sawing polypropylene pipes;

- screwdriver, to facilitate the procedure of fastening parts;

- metal shears for working with small parts;

- Bulgarian for cutting large parts;

- a hammer for hammering in reinforcement and leveling the tie;

- mounting tape and building level for measuring and aligning the frame to the horizon;

- marker for marking the details.

Hinges and fittings for the above frame will not be needed.

We make a greenhouse

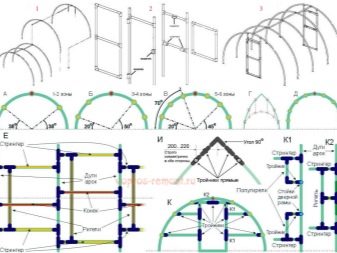

The step-by-step instruction for the manufacture of the greenhouse of the above sample includes several basic steps.

- The area under the greenhouse is leveled, the marking is made. For this, reinforcement is driven into the corners of the future structure to a depth of 40 cm. The angles are checked by level.

- Fastened tie from the boards on the armature. The rectangle is checked for evenness with the help of a cord that is pulled along diagonals. If they are equal, then everything is in order.

- On the long sides of the outside of the screed, reinforcement pieces are hammered in 75 cm steps. It should be 15 pieces on each side.

- Made the formation of the frame. A pipe is put on each reinforcement, bent and put on the reinforcement from the opposite side.

- So that the pipes do not fly off and do not push the reinforcement out of the ground, they must be fixed. To do this, cut out 30 pieces of the mounting tape of 10 cm each. They attach the pipe to the coupler, fixing the tape on both sides of the pipe with screws.

- Next, collect the ends of the wooden boards. In order to properly draw a picture, you need to use a drawing. So, the upper beams will be 60 and 123 cm in length for the average, vertical ones - 45, 140 and 170 cm, if you start from the edge. The evenness of the corners is checked by level.

- After the ends are fixed to the tie, you need to attach a pipe 10 m long in the middle of the roof of the structure for greater rigidity of the whole frame.To do this, use plastic ties.

- Next, cover the greenhouse film. The film is nailed to the bottom of the screed, putting wooden slats on it. After the film is fixed in the tensioned position, it is stretched to the ends, and then fixed to the bottom in the same way.

- At the end of the hole is cut a little smaller than the actual. A rectangle of wooden bars is hinged on its hinges, already covered with foil.

Views of the owners

Reviews of ownership of a greenhouse made of polypropylene pipes, mostly positive. And build a greenhouse, and fasten, and solder the parts can be improvised means, without resorting to buying or renting expensive equipment. Cheapness is the first positive quality that all gardeners pay attention to.

For many, the added benefit was the ability to do something for the garden with their own hands.

For the elderly, who have not the strength, the polypropylene version is ideal due to the low weight: you do not have to lift weights, straining your back.

Some people said that you can even make such a greenhouse without a preliminary drawing, that everything is clear.Others did not agree with them, because they built a year-round construction, making it a simple foundation. This is especially true of those who performed the greenhouse in the form of an extension.

The only flaw the owners complain about - This is what the frame can not always withstand the snow load, especially if there is heavy rainfall. However, this problem is solved very simply. You can either clean the roof of the greenhouse on a regular basis, or remove the film for the winter. The second option is only suitable if the greenhouse is seasonal.

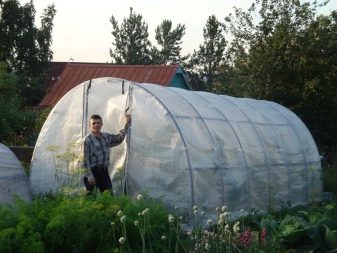

Examples of finished greenhouses

The complex construction of the greenhouse, which does not provide for the presence of the door, is suitable only for seasonal cultivation, since, having thus opened the greenhouse, all the heat comes out.

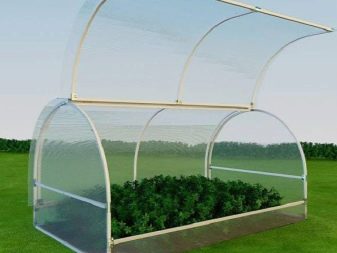

The use of fittings and hinges opens up a wide scope for the design of various greenhouse structures. The frame can be strengthened by fixing horizontal pipes, which are fastened with the help of connecting elements.

Polycarbonate is an excellent material for wrapping polypropylene frames.

It is much harder than the film, but it lets the sun through at the same level.

A greenhouse in the form of a house made of polypropylene pipes will perfectly fit into any surrounding landscape. Its design is somewhat more complicated than that of an arched one; however, if there is a clear drawing, everyone can create something similar in their own area.

When constructing low greenhouses, you need to think not about how to enter the greenhouse, but about the possibility to treat the beds and harvest. A “lid” made of polycarbonate is ideal for such cases.

The ends can be made not only from wood, but also from polypropylene pipes of greater rigidity. The result will be no worse.

Useful tips

Specialists engaged in the construction of greenhouses on a professional level, shared a few secrets of the construction of greenhouses.

- When constructing a greenhouse construction for year-round use, it is worthwhile to take a closer look at the more complex drawings, on which window leaves are provided. This will ensure optimal air circulation in the greenhouse. Plants will feel more comfortable, grow better.

- Having a greenhouse on the plot, you should try to make it oriented from north to south. So it will be constantly illuminated by sunlight.

- If there is such an opportunity, try to build a greenhouse on the foundation. An old base from a barn or other utility room will do. So you can reduce the risk that the greenhouse will blow away a strong gust of wind. After all, it weighs quite a bit.

- If the film or polycarbonate is fixed with screws, it is worth picking up samples with thermal washers. They will provide full tightness in places of fastenings.

- When working with polycarbonate, you should not remove the protective film from it until the entire greenhouse is collected. This ensures its good appearance after construction. It will not scratch or scuff.

How to make a smart greenhouse with your own hands, see the following video.