How to build a greenhouse from polycarbonate?

Polycarbonate greenhouses are among the most popular and sought after in the modern market. A huge number of advantages, among which high quality, reliability and practicality, qualitatively distinguish them from other varieties.

Special features

Greenhouse made of polycarbonate with their own hands is in great demand and popularity due to the cellular structure of the material. This is what provides an incredibly long service life, unlike glass or plastic film.

The distinctive advantage of polycarbonate is that it is not afraid of shocks, therefore it is able to cope even with such precipitations as hail or wind.In addition, this material does not deteriorate under the influence of direct sunlight and for a long time retains its transparency.

In order to understand whether the installation of a polycarbonate greenhouse is justified, it is necessary to understand the features of this material.

Polycarbonate is a lightweight and fairly durable plastic, consisting of several layers and having a cellular structure.

The most popular are sheets, the thickness of which does not exceed 6 mm. At the same time polycarbonate sheets can boast of impressive light transmission, as well as the ability to tolerate temperature extremes. Internal ribs provide incredible stiffness and strength, as well as the ability to take on virtually any shape.

Advantages and disadvantages

The enormous popularity and demand for polycarbonate greenhouses is provided by a number of advantages that qualitatively distinguish them from other varieties.

Among the most important advantages of such greenhouses are several factors:

- The ease of installation activities, as well as the ability to quickly install polycarbonate sheets.

- This material is considered one of the most favorable and effective in terms of thermal insulation.

- An impressive level of sound insulation that can reach 25 decibels.

- A good greenhouse must pass through direct sunlight. Polycarbonate in this context is unmatched, because its transparency level is not less than 92%.

- When using a special protective layer, you can be sure that green spaces will be protected as much as possible from ultraviolet exposure, which can harm the crop.

- Incredibly high strength and resistance to mechanical damage. In addition, polycarbonate boasts its resistance to rapid temperature changes, which makes it an ideal solution even for our latitudes. The strength of this material is almost 200 times higher than the strength characteristics of glass.

Of course, these are not all the advantages of polycarbonate greenhouses. One of the advantages are also their unique dimensions that allow them to be used for spansthat are created between the arches of frame structures.

Year-round use of the greenhouse has become possible due to the fact that polycarbonate sheets can easily cope with wind and snow loads.

Such greenhouses are also unmatched in the field of fire safety. Moreover, the plating used in the production of greenhouses is not subject to burning, as it can only melt, and then at a temperature that exceeds 500 degrees Celsius.

You can use ultramodern types of polycarbonate sheets, which do not emit any harmful substances even when burning or melting.

The polycarbonate greenhouse lining boasts impressive resistance to aggressive environments. In addition, a high level of plant protection against acid residues is guaranteed.

Polycarbonate greenhouses can also please their owners with a small mass, which is 15 times less glass. Due to this aspect it is possible to save a lot on the bearing parts of the structure.

Despite the huge number of advantages, polycarbonate greenhouses have certain disadvantages that must be taken into account before choosing such an object.

In no case should the ends of polycarbonate sheets be left open, as this will allow both moisture and insects to penetrate inside the greenhouse, which, in turn, may cause the appearance of fungus and other pathogenic bacteria.

Cleaning such a greenhouse should be done with the utmost care, as it is fairly easy to damage the surface.

It is best to limit the use of soft fabrics, as well as neutral cleaners. In no case can not apply cleansing compositions, which include salts, alkalis or chlorine.

And also Avoid abrasive pastes and sharp objects. which are able to scratch polycarbonate sheets, thus spoiling their attractive appearance and protective properties. In winter, close attention should be paid to snow removal from the top of the greenhouse. You can not allow the formation of ice, as it may in the future cause deformation of the greenhouse.

Materials

Careful attention in the process of manufacturing a polycarbonate greenhouse with your own hands must be given to the selection of materials on which the reliability, strength and durability of the whole structure depends.

Thin galvanized and aluminum profiles are considered ideal., and also options from metalplastic. Their main advantage is that they are fairly easy to assemble and can change their shape if necessary.

The only disadvantage of a greenhouse with a similar frame is that in case of bad weather, including heavy wind, the construction may not withstand, and the whole greenhouse will collapse.

If you are still planning to build it from such materials, then it is necessary to increase the number of ribs or to develop a special collapsible structure that can be removed in the winter.

One of the most popular in the modern market are greenhouses with a frame made of aluminum. Of course, a more durable framework would be if it was made of 3x6 cm thick timber, but this environmentally friendly material has its own specific drawbacks: if the greenhouse is in a region with high humidity, then the structure will soon begin to rot.

If you still want to use just such a frame, then it must be processed using special antiseptics,which will ensure a long existence.

The most durable is the construction, which was made of metal pipes or channel.

If you need a reliable greenhouse that can cope with any weather phenomena and mechanical stress, then it is best to choose steel options with a square cross section. Their only drawback is that they are practically not subject to change in shape, so use a sloping roof will not work.

It should also be noted that the use of a heavy frame requires a more solid and reliable foundation, which will be able to cope with a similar weight of the greenhouse.

Forms

A distinctive feature of a polycarbonate greenhouse, which qualitatively distinguishes it from greenhouses and other similar structures, is its ability to maintain heat. To heat the greenhouse uses natural sources, including the sun, vapors from manure or biological waste.

In order for steam to be covered as well as possible, it is necessary to reduce the amount of heated space. In addition, to work with plants it is necessary to provide for the presence of hatchways.

The main advantage of the greenhouse is that everything here is built on artificial heating, so the height of the structure can be much higher than the height of a person.

There are several types of the most popular and popular on the market forms of polycarbonate greenhouse structures:

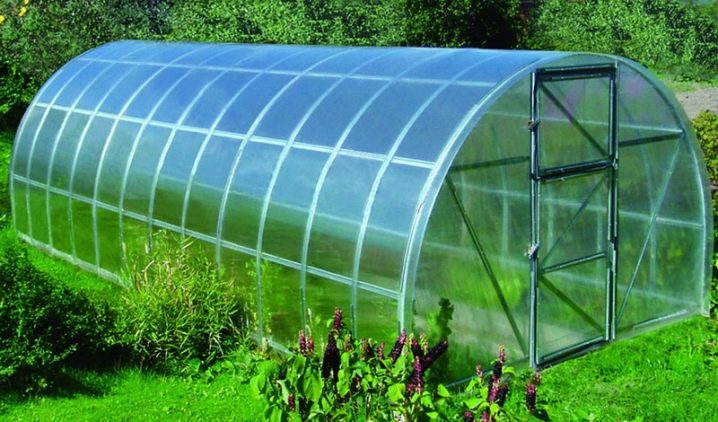

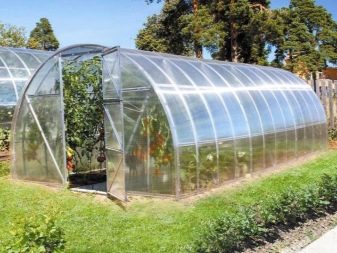

- Polycarbonate greenhouse arched view. This form is considered optimal because it provides a high level of comfort during launch and use. The assembly is carried out by bending polycarbonate sheets and gluing them to the frame, thanks to which people can easily and comfortably move inside the greenhouse. The presence of an arched roof allows you not to linger on the snow and other precipitation.

- Mini greenhouses. The main feature of such structures is their small width, which rarely exceeds 2 m. In addition, these greenhouses are low in height, but this does not affect the smooth movement of a person to full height. In most cases, the height of the greenhouse is about 2 m.

Such options are considered the best choice for people who own small areas and wish to use them for the construction of this structure.

- Greenhouses "droplet". The highlight of these building objects is the presence of a pointed ridge roof, thanks to which the structure is able to cope with the strongest winds and snowy winters. Snow does not stay on the roof, so that the load on the entire object is minimal.

- Butterfly greenhouse. Understand the design features can be based on the name. A convenient greenhouse consists of shutters arranged parallel to each other, which cover the roof of the greenhouse. Such designs are commonly used for growing seedlings.

- Greenhouse bread boxmade of polycarbonate. This structure is distinguished by its small height and arched shape, and the working area is usually located on the south side.

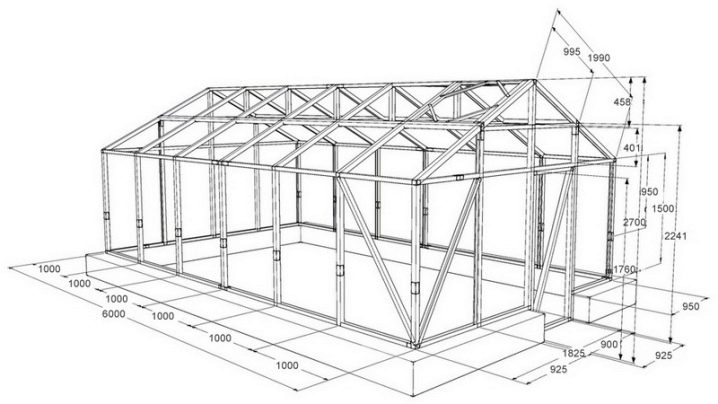

Dimensions

In the process of building a polycarbonate greenhouse, close attention should be paid to the size of the sheets. Knowing the dimensions of the sheet, you can make calculations of the frame, choose the optimal type of construction - arched structure or a building with a dual-slope roof. It is best to use six-meter polycarbonate sheets, with which you can build arched greenhouses. The pitch of the elements should be no more than 2100 mm.and the length of the greenhouse depends on the needs of the owner and the size of the territory.

To build such a design, it will suffice to select polycarbonate sheets with a thickness of 8 mm. Such material can easily cope with snow loads in winter, but it is also very convenient for installation.

If the greenhouse includes walls and a gable roof, then each plane is installed separately. If you want to save, you can use walling made of inexpensive materials, whose thickness will be 4-6 mm.

Required tools

To create the highest quality and durable greenhouse you will need to use reliable and accurate tools, including roulette, shovel, hammers and nails. In addition, it is impossible to do without such materials and tools as metal structures and square-shaped pipes, thermo washers and wooden boards, concrete mixers, primers and welding units. These devices are necessary in order to build a greenhouse with a concrete foundation.

Careful attention in this process should be given to the fastening of polycarbonate sheets, as they are under enormous pressure every day during use. That is why The installed thermo washers must be of high quality, and their installation must be carried out as responsibly and carefully as possible.. Only in this case will it be possible to build a polycarbonate greenhouse that will meet all modern standards and will be able to serve as long as possible.

Preparatory work

It is quite easy to assemble a greenhouse from polycarbonate sheets and other components, therefore practically anyone will cope with this process. However, to ensure a long-term existence is impossible without a quality foundation, and only a professional can already cope with this.

Without the necessary knowledge and skills to build a cool concrete foundation will not work, and without this there can be no question of the long-term use of polycarbonate greenhouses.

That is why it is extremely important to know how to mount the precast base correctly. Given the fact that the polycarbonate greenhouse is extremely small in mass, can be limited to tape or cement base.

Careful attention when pouring the foundation must be paid to ensure that it is eventually even, otherwise the greenhouse will be crooked, which greatly increases the risk of mechanical damage.

Close attention should also be paid to the study of drawings and diagrams, on the basis of which the polycarbonate greenhouse will be built step by step.

Foundation

To ensure maximum durability and rigidity, polycarbonate greenhouses should be attached to a fixed base. Given the small mass of this structure, we can limit the use of a point foundation, which is made of any strong material. It can be timber, brick, blocks of aerated concrete and so on.

The distinctive advantage of the foundation of the timber is in its affordable price, despite which it is able to withstand greenhouses weighing up to 120 kg. In order to prevent erosion of the soil, as well as to protect plants from sudden changes in temperature, it is best to bury it in the ground.

There is no need to completely wrap the timber into a film, as due to condensate accumulation, the structure will quickly become unusable. In order for the bearing pillars not to be washed away with water, it is necessary to put a pillow of sand or rubble under them.

One of the most popular today are foundations of timber, for which old sleepers can be used. The main advantage of this material is that it can last for at least 40 years even in conditions of very high humidity.

Sleepers must be laid in a small trench in such a way that the upper edges are at ground level, and they can be stapled using construction brackets. Piles under a similar foundation can be made from concrete, from blocks and bricks.

If the greenhouse is on the construction of metal, it will be necessary to establish a strip foundation. The main disadvantage of concrete is that it is a rather poor conductor of heat, therefore it warms up for a very long time, which is not very good in severe and winter cold. That is why similar foundations can be erected only in those premises that will be distinguished by the presence of artificial heating.

Frame

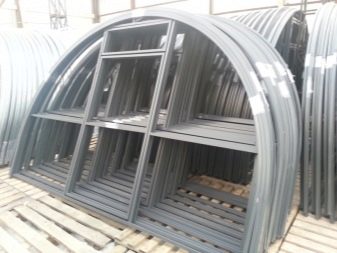

If you buy industrial-made frames, they usually have all the necessary fasteners, but to simplify the work you need to have on hand the following tools: pliers, screwdrivers, tape measures, screwdrivers, markers, handsaws or a construction knife.It should be noted that the manual for the assembly of polycarbonate greenhouses with their hands may differ depending on the manufacturer, but the general recommendations are the same for almost all models and forms.

So, the installation of the frame of the greenhouse should occur, including the main stages:

- The assembly must begin at the ends. The central arched part should be connected to the vertical posts, which can be done with screws and special fixings that come with the kit. It is best to do this on the ground, since in an upright position certain problems may occur with evenness.

- After the butt is installed on the foundation, it is necessary to carefully check the level of verticality. If everything is in order, then attach the anchor bolts.

- The crossbar should be grafted right in the middle of the arch. In addition, the same parts will need to be installed on both vertical supports. Therefore, it is extremely important to use the tape measure all the time so that the guides are at the same level, otherwise in the future there will be a strong pressure on certain elements, which will significantly reduce the life of the structure.

- After the arch is assembled, it is necessary to make sure that all corners have been correctly observed. Only then can the vertical supports be fully attached to the base of the greenhouse. It should also take into account the fact that the step between the arches can not exceed 2 m, due to the width of a conventional polycarbonate sheet.

- And you also need to do all this with the rest of the arches and crossbars, not forgetting to check it all the time with the help of the level.

- Once all levels are checked, the arches are installed, you can proceed to the installation of doors. Initially, it is necessary to mount the frames and additional stiffeners. After the doors are attached, you need to make sure that they work. It often happens that the door does not close or hurt the frame when closing. In addition, there are quite frequent cases when the door opens by itself, which may mean that the opening is uneven. It will be necessary to do all the work anew, since a completely hermetic door is one of the most important conditions for the correct operation of the greenhouse.

To remedy the situation, it will be necessary to completely disassemble the structure or part of it, and then assemble it correctly, carefully checking all the nuances and angles.Careful attention should be paid to stiffeners, which should be a single plane.

At this stage, the installation of the frame of the greenhouse ends, and you can cover it with polycarbonate sheets.

Roof

Arrangement of the roof in a polycarbonate greenhouse requires special attention, because the strength and reliability of the entire structure, as well as the integrity of the plants, depend on this element. It should be noted that the type and shape of the roof depends primarily on the design and features of the greenhouse.

Some use plastic film to save as the main roof covering, but this material cannot boast of durability and reliability. In addition, because of its fine structure, the polyethylene film practically does not retain heat and passes the cold inside the greenhouse.

If there are no funds for other types of roofs, then You can use this option, but in several layers, thanks to which it will be possible to create an air layer between them. It is she who will play the role of an excellent thermal insulator, which is so necessary for a polycarbonate greenhouse.

Among the advantages of plastic film as a roof for a greenhouse, elasticity can be distinguished, minimal expansion with temperature drops,Affordable price and high UV pass rate.

It should be noted that if the film was used throughout the summer in a hot region, then in winter it will need to be replaced, because under the influence of frost, it will become brittle.

The main disadvantage of the film is the fact that in the process of applying it appears condensate, which reduces the light transmission ability of this material.

In the process of designing a roof profile it is necessary to proceed from the load on it. This indicator is extremely important in winter, when precipitation is characterized by the greatest mass and leads to increased load on the greenhouse cover. Roof profiles can be flat as well as single-slope or double-slope.

The flat roof is one of the least popular, since here in winter a huge amount of snow is collected.that puts pressure on the whole structure, and it can simply not withstand.

It is best to give preference to the arched structure, the distinctive advantage of which is that it evenly distributes the load over the entire polycarbonate greenhouse.

The only drawback is that on the sides of this roof can not boast of an impressive height, which takes the usable space from the greenhouse, since there can not be grown tall plants. However, there is a way out, because on the sides you can always organize the cultivation of seedlings, and then transplant them in the central part of the room.

A distinctive feature of a gable or single-pitch roof is the presence of a cone, which is the top of the roof. The strength of the structure as a whole depends on its quality, and it is easy to make such a roof when building a greenhouse on your own.

Structural casing

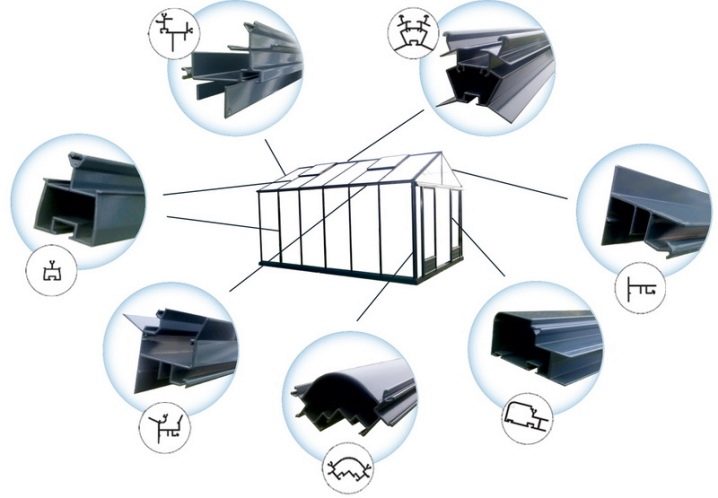

If the frame is already fully erected, you can begin cutting polycarbonate sheets for the greenhouse and fix the trim. To date, there are two optimal mounting methods. The first is to use special washers that are resistant to high temperatures.

As for the second, it involves the use of a profile for polycarbonate. Profile fastening is made thanks to a special profile, which can be found in a variety of colors.The most important thing here is to correctly identify attachment points, the number of which depends on the length of the sheet and the complexity of the frame itself. Most craftsmen are advised to install between the profiles of the frames a special waterproofing, which will not allow the flow of the greenhouse in the future.. The peculiarity of this method is that the joining of sheets takes place on the frame, which greatly simplifies the installation process.

It should be noted that installation using a thermo washer is slightly different from the method described above. The main difference is that the sheets are mounted directly on the frame of the greenhouse, strictly following the principles of waterproofing. To do this, you need to choose the most durable and reliable thermal washers, since they carry the main load on the retention of polycarbonate sheets.

In this case, it is not worth saving, as the strength and durability of the whole structure depends on it.

Installation of cellular polycarbonate on the greenhouse is made in a certain order:

- It is necessary to carry out calculations, and on the polycarbonate sheet it is necessary to make several holes where the sheet will connect to the frame.

- The thermo washer has a special hole where it will be necessary to install self-tapping screws.

- Polycarbonate sheet to be placed on the frame and connect it in the desired position. Here you need to get an assistant who could keep the sheet in the process of its attachment.

- After all the fixing work is completed, the thermo-washer should be closed with the help of plugs, which are usually included in the kit. They are necessary in order to ensure maximum protection of the structure from moisture.

Interior arrangement

In the process of internal arrangement of the greenhouse it is necessary first of all to do the ground. In order for the selected soil to fully fulfill the functions assigned to it, it is necessary to pay close attention to its selection.

First of all, the ground should be provided with good air permeability and optimum humidity level. In addition, it will be necessary to add special nutritional supplements to the soil and clean it from weeds. For disinfection should use special tools for this type of soil. Soil can be purchased in specialized stores or cook it yourself.

The internal arrangement of the greenhouse also implies a competent design of the beds. And some believe that in this case it is necessary to be guided only by the amenities for the gardener, but this is not so. Improper placement of beds can cause a lack of harvest in the future.

The optimal and effective way is the arrangement of the greenhouse according to Mitlayder. The essence of this technique is that for optimal plant life, the beds must differ by a width of at least 45 cm, and the passage must be at least 90 cm. It is in such cases that plants can receive the required amount of air and sunlight either cultures.

It is best if the beds in the polycarbonate greenhouse go from north to south. Of course, the yield depends not only on this, but also on the correctness of watering and caring for crops.

Almost any modern greenhouse boasts windows and doors. This means that ventilation can be carried out not only with the help of technological equipment, but also manually. For this it is enough just to open and close the vents in time.

Now it's time to take care of the heating of the polycarbonate greenhouse, which can be carried out in the sun. However, in some regions this is not enough, especially in the winter season, so you have to resort to installing special heating systems. One of the most popular on the market today is to install underfloor heating.which differs in availability, the low price and efficiency. The ease of construction of such a system allows you to install it at home on your own.

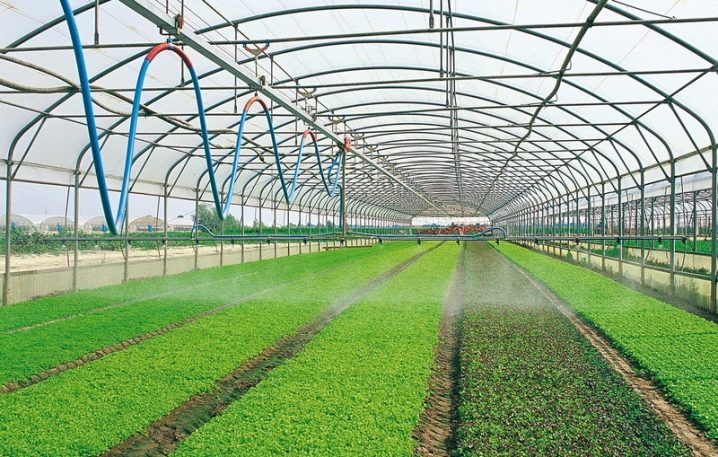

In order for the crop to grow as quickly and efficiently as possible, it is necessary to take care of a modern irrigation system. Of course, you can use barrels or a hose, but this method of irrigation is not very convenient and involves the constant presence of the owner in the greenhouse.

In the presence of a sufficient amount of finance can be installed drip irrigation system, which is different automatic irrigation and can save a huge amount of time. A distinctive feature of this method is that watering will be carried out with the help of water droplets, which directly go to the roots of plants.

Thus, the internal arrangement of the greenhouse involves the observance of a huge number of points. Only a well-organized space and the use of quality systems makes it possible to get a good harvest.

Tips

In order for the greenhouse of polycarbonate gave a great harvest, it must be placed in the right place. Ignoring the minimum requirements can negate all the work.

First of all it is necessary to pay attention to the features of the place where the greenhouse structure will be located. The vast territory must be completely open in order to receive direct sunlight throughout the day. In addition, the wind rose is of paramount importance, especially in areas with strong cyclones. That is why experts recommend placing a greenhouse from west to east, so that all end parts of the structure will be directed north or south.

There is no need to install a greenhouse far from the house itself, as this will lead to certain inconveniences in the process of caring for plants.

If there are already other economic structures on the land plot, then a greenhouse can be built in close proximity to them.Thereby It is possible not only to effectively and efficiently distribute useful land area, but also to protect the greenhouse from the cold wind.

Careful attention must also be paid to the organization of an optimal home-made microclimate in the greenhouse itself.

To make it much easier to maintain an optimal indoor temperature, when installing the frame, you can slightly deepen its base. Just half a meter is enough to keep moisture and heat in the air as long as possible.

It should be extremely careful, as low plants may be in the shade and will not be able to receive a sufficient amount of sunlight.

Thus, making a greenhouse with your own hands is a simple process if you approach it responsibly and competently. The most important thing is to use high-quality materials in the construction process and to carry out their reliable installation.

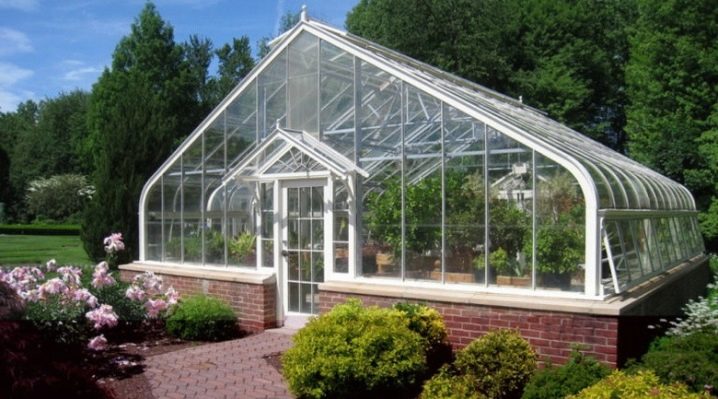

Beautiful examples

Beautiful greenhouse from a solid foundation. The design is made carefully and with a certain diligence. There are no flaws: only high-quality and modern materials were used.

A greenhouse can be beautiful if you turn it into a comfortable holiday home.For this you can use transparent walls, so that it will look like a greenhouse or a winter garden. This option is suitable for people who can not live without plants or want to engage in gardening.

Effective organization of space. Strict adherence to the tips allowed us to correctly set up the beds and make rational use of every centimeter of polycarbonate greenhouse. A distinctive feature of this option is a non-standard roof.

How to collect a greenhouse from polycarbonate with your own hands, see the next video.