Furnaces for greenhouses: the types and features of the device

The crop depends on weather conditions, in particular, on the temperature in the greenhouse. In regions with a harsh climate, for a timely harvest, special structures are constructed that warm the greenhouses. Their size and quantity depends on the area of the greenhouse. Since the heating devices will be used for a long time, substantial material costs are required for the equipment. Consequently, the cost of the crop will increase.

Types of heating and types of stoves

Greenhouses are heated by several methods:

- biological;

- electric;

- air;

- gas;

- stove.

Stove heating is the most economical heating option that allows the use of most fuels.They can work like wood, coal, gas, and even pellets.

Furnace heating has one major drawback - the overdrying of air due to the rapid heating of the equipment.

- Furnace heating on sawdust, which is waste woodworking enterprises. Therefore, the purchase of this fuel does not need large expenses. For the construction of the stove on sawdust, you must purchase a barrel of tin, preferably a couple of barrels, a gas cylinder and a pipe segment.

- A waste oil stove is an economical heating option with a long burning. Those subject to oil refining are disposed of from any vehicle fleet, so fleet workers will be happy to share the oil.

- In the cold season, stoves are used for heating the greenhouse, which provide good heating.

- Kuznetsova's brick heating stove arouses special interest among gardeners due to the high efficiency (80%). However, the body of a brick stove must be insulated with basalt material.

- A miracle-stove on diesel is an excellent solution for a greenhouse where there is no connection to the central heating system. The stove is also used as an extra,and as the main source of heat.

There are many types of furnaces for heating greenhouses, which differ from each other:

- heat transfer principle;

- convection;

- radiation;

- basic and additional details;

- combustion chamber;

- pipes for air supply.

The design and installation of a specific furnace can be carried out only after studying all the details of the heating process. You need to know that the furnace for large greenhouses and small different ordering.

Fuel options

Greenhouse heating involves the use of various types of fuel. The most affordable fuel is firewood. The design of the wood equipment does not represent anything difficult. Firewood can be stoked and long burning stoves. For a small greenhouse it will be enough to load fuel once a day.

Coal can be used for better heating., its main advantage is high calorie content, and disadvantages - a lot of waste: ash, dust. And also during the combustion of coal, harmful and toxic gases are emitted into the atmosphere, and some types of coal can even ignite spontaneously if storage conditions are not followed.

Recently sawdust has been used as a fuel for heating. Furnaces in which they produce heat are referred to as long-burning structures. High-quality heating is accompanied by a little smoke. This option of the furnace is easy to perform independently. The stove has a fairly high efficiency.

Greenhouse facilities can also be heated by stoves in which fuel briquettes are used as fuel. Such fuel, in comparison with coal or firewood, has better characteristics, for example, less smoke, quick heat and no harmful effects on the air. The use of fuel briquettes allows you to avoid sparking, and long burning - to maintain the required temperature. The stove with this type of fuel has high efficiency, environmental friendliness and efficiency.

Some summer residents use liquid as fuel. However, it is not quite suitable for heating due to its toxicity and high cost.

Optimal choice

The best option for heating greenhouses is to install a stove stove, which is considered the most economical and easy to use.The heater consists of a barrel with a door for the firebox, a chimney, a pipe for the heat to come out, a jumper in the upper part.

Heated due to the movement of smoke:

- Hot smoke moves through the pipe, the pipe is installed either on the sides of the greenhouse, or in the center.

- The surface of the furnace radiates heat.

- Warm air is formed above the web and goes out through the pipe.

Lumber waste, coal, or firewood can be used as fuel. The quality of combustion depends on the type of fuel and the penetration of air into the furnace space. This method of heating is suitable for those who can often control the process of burning. This is the only drawback of the stove.

In long burning furnaces, this minus is an advantage: in them fuel can be enclosed much less often. They also consume less fuel and reduce heating of the furnace walls without reducing heat transfer. They are very similar in characteristics with infrared heaters.

A long burning furnace has two chambers, one of which completely burns residual fuel, and the other burns only the main part.The access of oxygen to the chamber is limited, as a result of which the fuel does not burn immediately, but smolders for a long time with the release of a large amount of heat.

As a fuel for long-burning stoves, various household waste can be used, but without harm to plants. The constancy of temperature in the greenhouse provides the necessary conditions for the growth of crops.

However, before installing such a furnace, it is necessary to take into account many factors.

Central wood construction: the pros and cons

The central wood construction is made of metal or brick materials. Moreover, the larger the greenhouse, the greater the furnace design. It was called central because of the need to install it in the middle of the greenhouse, which allows optimal distribution of heat over the entire area of the greenhouse.

This design works on wood, so special devices are not required for operation.

Central wood stove has a considerable number of disadvantages.

- Frequent watering of plants and constant air moistening in the greenhouse. Due to the rapid heating of the air dries quickly, and hence the soil.Some crops do not tolerate such a climate in the greenhouse. Installing water barrels near the stove will allow this disadvantage to be slightly compensated.

- Another important point is the uneven distribution of hot air over the entire area of the greenhouse. The highest temperature will be maintained near the furnace, and the farther the plant, the colder the air will be. As a result, some of the plants will freeze around the perimeter. This should be considered if the greenhouse is large and has a high ceiling.

You can equalize the temperature with the help of induction lamps of long burning. They are located in the most remote parts of the greenhouse. And also heating with an infrared heater will allow to keep cultures. This option is not suitable for greenhouses with low ceilings: you must make a choice in favor of a wood stove or induction lamp. If a stove is chosen, then near it is necessary to install small fans to accelerate heat.

Bubafonya

Oven stoves have a small efficiency and the need for frequent reloading of fuel. The craftsman Bubafonya invented a self-made design, which is distinguished by the principle of combustion of fuel.

Features and device

The main difference in the Bubafoni furnace is the upper air mass intake, which led to such positive properties as:

- longer burning fuel;

- there is no need for frequent loading of the firebox;

- better heat retention;

- profitability, because such a furnace can be made from scrap materials: barrels made of iron or metal; Not only firewood can be used as fuel, but also boards, chips, cardboard or chips. And also the Bubafonya stove operates autonomously, that is, without the use of electrical energy.

There are also disadvantages of this design:

- outwardly looks unpresentable;

- average heat emission;

- carbon formation on the furnace walls;

- condensation is formed, which in winter freezes and closes the main pipe;

- during the intake of air, fire sometimes appears from the duct;

- with the installation of such a stove, it is necessary to take care of ventilation in the greenhouse.

In order to independently make Bubafon, it is necessary to know the structure and principle of operation of the furnace. Air enters through the top pipe, and the fuel starts to burn. When burning, the ash will accumulate on the surface of the fuel and prevent it from burning.Because of this, you need to take care of installing the press in the form of a metal pancake, the diameter of which is slightly smaller than the barrel. In the middle of the pancake is drilled a hole for the pipe with oxygen.

The fuel is burned, and the press is lowered, removing the ash between the pancake and the wall. This ash cools and goes through the chimney with the rest of the combustion products.

Manufacturing

Having studied the drawings and diagrams of the furnace, having understood the principle of operation, you can do Bubafon with your own hands. An important point is the choice of capacity. As it can be used a pipe of large diameter, a barrel, an empty gas cylinder.

Whatever it is, will have to finish the construction:

- get rid of the lid;

- to obtain an open top tank, it is necessary to brew the bottom;

- press preparation: a metal circle is suitable for this;

- drill a hole in the center of the pipe and attach the pipe by welding;

- a pipe with a larger diameter is also welded to the lid so that the first pipe can slide freely;

- to create a gap so that the air passes between the surface and the fuel, fix a metal profile to the pipe;

- for the firebox to make the door of the iron sheet and attach;

- from the top of the tank, make a hole for the chimney and attach a pipe;

- make legs for the stove, if the bottom is not "worth it."

In the manufacture of the chimney must take into account the need to create resistance, which will allow a longer delay of heat.

Before installing the furnace, it is necessary to make a foundation for it from bricks and a substrate made from galvanized sheet. This will help to avoid heating the lower part of the stove, which leads to the death of closely growing crops. The foundation also stores and distributes heat.

After installing the furnace, it is necessary to impose bricks to improve heat transfer.

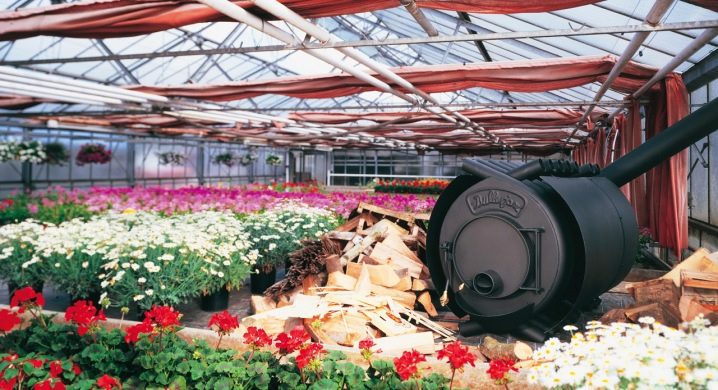

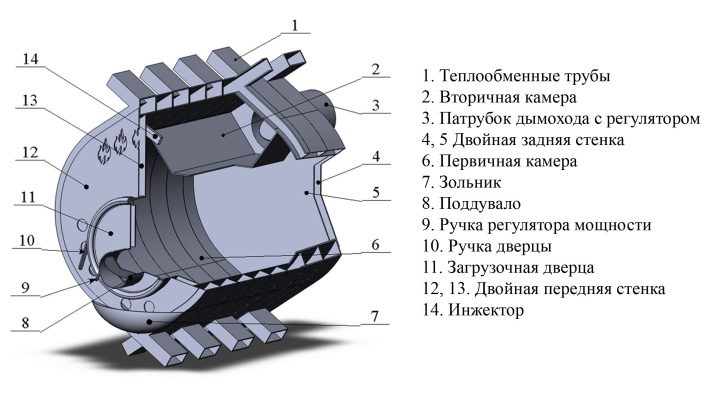

Buleryan: distinctive features

Buleryan - a long-burning stove, very similar to the stove. Here, too, the air is heated by hot smoke from the pipes around the perimeter of the greenhouse, becoming also hot. In contrast to the stove, in Buleryan the air heats up differently: cool air enters the lower opening of the pipe and begins to heat up with the body of the flue space, where the pipes adjoin. As a result, cool air heats up to 60 degrees and leaves through the top opening. Furnace fuel: firewood, coal, pellets, sawn waste.

Buleryan, unlike the stove, has several advantages.

- Greater efficiency due to afterburning of flue gases. As a result, less fuel is consumed, and more heat is produced.

- Complete combustion of fuel.

- Having flooded Buleryan once, she can work for three days, which greatly facilitates the work of the gardener. For people who can not fuel every day, this is a great option.

Often, Buleryan is called a design without flaws, but still there is one drawback that is not related to the furnace design, performance and efficiency: the release of caustic components that are not recycled.

Initially Buleryan was used by lumberjacks of Canada, who often had to lead a nomadic lifestyle. Therefore, the furnace had to ensure safety and heat the room as quickly as possible.

To quickly heat the greenhouse, you must maintain a constant burning process.However, Buleryan works mainly in the mode of corruption. With constant intense burning, the metal surface of the furnace will soon burn out.

Dry chips, cardboard, paper are used for the ignition of the furnace. The main thing is to keep them dry and burn quickly.The burning process is monitored through a glass door or choke. When the fuel turns to coal, fuel is again thrown up. You can not use coal as a fuel, as Buleryan - wood stove. It does not take much time to heat even a large greenhouse.

It is strictly forbidden to raise the temperature in the furnace to ultra-high temperatures. Firstly, the metal surface will burn, secondly, excessive heat will go outside, as the thermal conductivity of the pipes is limited, as a result of which excess heat is not transferred to air. And also coke is not recommended as a fuel - this will lead to a breakdown of the device.

When installing Buleriana must adhere to the rules of fire protection. The furnace is installed on a non-combustible surface, for example, on bricks laid flat or on a metal stand.

In the manufacture of their own furnaces an important element is the chimney, to which the requirements are:

- chimney material: brick, concrete, metal;

- chimney parameters.

There is no difficulty in installing the stove Burelyan, it is enough to prepare a place, correctly make a chimney and you can start heating.

On the types and features of furnaces for greenhouses, see the following video.