Types and stages of construction of greenhouses

Unfortunately, not the whole territory of Russia is conducive to growing own vegetables and fruits for many months. In most climatic zones of the country, the summer season is extremely short, while many people tend to grow as many crops as possible on their plot for their subsequent harvesting. In this connection, gardeners and gardeners readily use greenhouses, with the help of which the growing season is increased, which makes it possible to harvest early and more abundant. In some cases, if there is a well-constructed greenhouse, personally grown crops can be consumed year-round.

Of course, for these purposes it is necessary to take into account a number of features, which we will discuss in detail in this article.

Special features

The greenhouse built with its own hands always warms the gardener's soul. The design can be of the most different size and shape, and home-made greenhouses are no worse in use and functionality. The device can be easily seen in the diagrams and drawings, materials for the manufacture can be different. Often, fiberglass reinforcement is used as a frame, and there are no problems with a removable covering material either - basically it is polyethylene film, glass or polycarbonate. Considering all these features, it is possible to build such a construction on the site in one weekend, and the improvised buildings are in no way inferior to the quality acquired in the store.

Advantages and disadvantages

Convenient homemade greenhouses are very popular among summer residents. The undoubted advantages can be attributed to the fact that the greenhouse made at the dacha itself will be relatively cheap. The budget greenhouse can be made of different materials, the most important thing is to equip it with an opening roof and take care of the quality of lighting for the plants.Speaking about the minuses, of course, you should take into account that you have to spend time studying the types and structures, as well as to get acquainted with the drawings and plans for construction in the country.

Kinds

Greenhouses are designed taking into account the botanical characteristics of those plant species for the needs of which the greenhouse is built. This also includes the amount of transmitted light and the temperature inside. Greenhouse can be both year-round and used in a certain season. In general, all types of greenhouses are suitable for growing a variety of crops - be it Chinese cabbage or flowers.

At first approximation greenhouses can be divided into the following categories:

- single-pitch;

- gable;

- drop-shaped;

- dome;

- polygonal;

- Dutch

- In most cases, shed roofs are used in the construction of greenhouses or conservatories, since this type of building has a passage. As a result, it is easy to enter the premises without regard to weather conditions. This type of greenhouses is best installed on the south side of a residential building.

- Greenhouses with gable roofs are very popular in our country and are currently the most common design.

- A teardrop-shaped greenhouse is a very durable construction, it perfectly passes sunlight, does not hold snow on the surface, but it is rather difficult to install, therefore such greenhouses are rarely made independently.

- Dome greenhouse has a spectacular appearance and does not require a large consumption of materials, but its main advantage is that due to the design features it can be installed in areas with seismic danger. The main tasks in the construction - good sealing and high-quality insulation.

- Polygonal greenhouses delight the eye, perfectly transmit light and are not afraid of gusty wind. The difficulty in installation is that it is necessary to carefully organize the space in order to evenly distribute the heat inside.

- The Dutch version of greenhouses is reliable and durable. Because of the sloping walls, sunlight penetrates inside, which allows to significantly increase the yield.Among other things, this option is also quite budget.

- Recently, the so-called "booths" have become widespread among summer residents. Most often it is built for the cultivation of tomatoes and peppers. This type of greenhouses is functional, convenient, does not require large expenditures, allows stably receiving a good harvest, which allows to call it the optimal type of self-built on the site.

Also greenhouses are divided according to the principle of movement:

- folding;

- stationary.

Folding greenhouses began to gain popularity relatively recently. Their advantage is that the light frame is easy to fold and move to another place in the backyard if necessary. At the same time, the greenhouse itself is very ergonomic and has a low cost, which is what merchants' attention deserves.

Stationary greenhouses, by contrast, have long become classics of the genre. To install the structure of this type will require an underground basement and frame made of metal. Many people have long preferred this type of greenhouse, because over the long years of operation in a variety of conditions, these structures have gained fame as strong and durable devices.There is no particular difficulty in installing such a greenhouse, it is also quite easy to maintain.

Also greenhouses can be divided according to the type of initial characteristics - these types of greenhouses are named after the name of their creator:

- greenhouse in Kurdyumov;

- greenhouse on "Mitlayder."

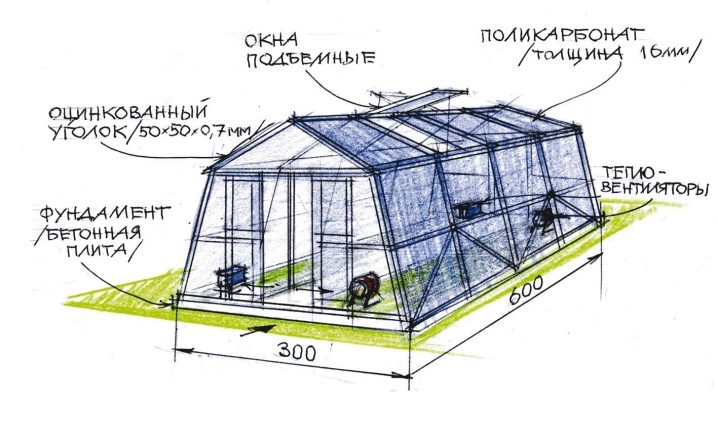

Greenhouse Kurdyumov is an autonomous unit, otherwise it is called "smart." This design is characterized by the ability to automatically maintain the temperature inside it, a special plus is the presence of drip irrigation of plants, which does not require human intervention. This type of structures supports the possibility of natural soil restoration in the beds or in containers with plants. Greenhouse Mittleider is considered a special subspecies of greenhouses. Its distinctive features are the know-how in the air ventilation systems in the room, the special arrangement of the frame - beams and struts create a solid construction for the covering material. Usually such greenhouses are located from east to west, which opens up broad opportunities for plants to perceive sunlight.

Natural boards are commonly used as the base material for the Mltlider greenhouse.that allows you to "breathe" and prevents the formation of condensate.As a rule, such greenhouses have a large size, which gives an additional opportunity to create a special microclimate for plants inside. Usually a greenhouse looks like a low building with a gable roof with a difference in height. Another possible option is an arched building with a roof of two levels.

Another option of greenhouses - a three-row greenhouse. As a rule, such buildings occupy a medium or large area, the beds in them are located in three levels, two passes are located between them.

Farm greenhouse consists of a metal frame, over which the film coating is stretched. This type of greenhouses is very loved by the population, because it has low cost, it is moisture-proof and resistant to environmental influences.

Many gardeners fell in love with a spherical greenhouse for its unusual appearance and excellent transmission of sunlight.

Specifications

When choosing consumables for future construction, be sure to pay attention to what time of year the greenhouse will be used predominantly.

Winter greenhouses must be equipped with a heating system., it is better to install them close to the heating system at home. In another case, as an additional equipment, you can put an oven in a greenhouse, but this will create additional difficulties - the oven requires additional attention, it needs to be heated and, most importantly, it must be kept out of overheating, which is fraught with temperature fluctuations. Winter greenhouse must be installed on a solid foundation, among other things, this type of construction requires additional strengthening of the frame and roof in order to avoid possible damage due to heavy snowfall.

There is also an opportunity to build a so-called “greenhouse thermos” on the site - this structure can boast a characteristic of special strength, since its foundation goes into the ground by two meters. However, the installation of such a construction has a number of additional difficulties - it is necessary to dig a foundation pit, the foundation must be separately strengthened to avoid deformation, and thermoblocks are usually used as the material for the walls, which will then need to be warmed. All this is quite expensive, so on the gardens such greenhouses are rare.

Summer greenhouses in most cases represent a frame on which a polyethylene film is stretched. This version of the outer skin is the most budget, and with careful use of the film is quite capable of serving two seasons.

Creating the easiest greenhouse on the summer cottage with your own hands requires certain preparatory work.

The first thing to take care of is to prepare the site for construction. Try to choose a site as smooth as possible, it is also highly desirable that there should not be any obstacles to the ingress of sunlight. Further, the site is properly tamped. If the tree is chosen as the base, then the prepared boards are treated with an antiseptic solution and are knocked around the perimeter. In the corners of the boxes, reinforcement is installed as an additional reinforcement. If for some reason it is not possible to allocate a separate place for the construction of a greenhouse, an alternative option would be to adjoin one wall of a greenhouse to any building - this could be a residential building or some utility room.

When choosing a material for the frame, it is necessary to take into account all their characteristics. We must not forget that the frame itself and the doors must have special strength so that the structure could not be damaged by wind, temperature fluctuations and snow masses during the winter period. None of the frame elements should be massive and prevent the penetration of light. If a collapsible design is intended, it should consist of lightweight materials and be able to be dismantled without additional effort.

Frameworks for greenhouses can be made of the following materials.

- Tree - the most environmentally friendly and easy to use material that does not require the use of any professional equipment and does not imply specialized skills during the work. Since the tree tends to rot, special attention should be paid to its pretreatment.

- Aluminum profiles suggest the creation of a rigid but lightweight frame, while it is durable. This material has a higher cost, its use requires the use of equipment for fastening parts together.

- Plastic (as well as metal-plastic) parts have a low specific weight, are strong enough, are not subject to external influences such as rotting or corrosive changes. Due to flexibility, it is possible to change the shape of parts, which provides ample opportunities for creating greenhouses with arches or two ramps. But it must be borne in mind that plastic elements require mandatory attachment to the foundation or the ground.

- Steel frames They are also quite widespread, but they need a tape base. If the elements are galvanized, they will last longer, as they are not subject to rusting and corrosion.

- Drywall It is a successful combination of low material weight and ease of operation. Practice shows that the frame of this type of material is inexpensive, easy to use, long enough to serve and easy to disassemble. Gable, arched greenhouses, and Mitlider greenhouses are excellently created from it.

Sometimes window frames are used as frames - which are characterized by excellent thermal insulation and relative ease of installation.However, it is necessary to take into account their relative fragility - even with careful care, the service life will hardly exceed five years.

The next step in the process of building a greenhouse after choosing the right place is to choose a suitable foundation. Its type directly depends on the weight of the planned structure, since in most cases the framework of greenhouses weighs a little, and the harboring material additionally adds to the construction of the sail, which often causes destruction due to strong gusts of wind.

- The foundation of brick is simple to install, reliable and well suited to most greenhouses. But it is necessary to take into account that laying a brick foundation requires specific skills and is rather expensive.

- Stone foundations are rightfully the most durable and durable. On it you can install heavy metal frames. This option can not be called a budget, as a rule, stone foundations are created for capital greenhouses.

- Concrete is inexpensive and freezes quite quickly, but requires the creation of formwork and frame fixings.

- The tree is often used as a foundation, but it is worth consideringthat the wooden base is not suitable for capital construction, since it is unlikely to last longer than five years even with the most caring care.

- In some cases, the construction of a greenhouse is quite possible to do without the foundation. We are talking about portable greenhouses of small size, the windage of which is reduced by attaching directly to the ground with small pegs.

When choosing a material for coating, it is necessary to take into account all the advantages and disadvantages of different types of materials.

Basically, use the following options:

- polyethylene film;

- glass;

- polycarbonate.

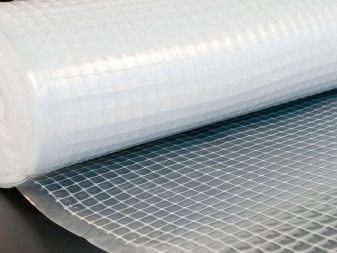

The most affordable type of covering material is stretch film.however, it cannot boast of durability and even the best quality coatings need to be replaced every three years. A greenhouse with arches or arcs is usually covered with two layers of film, which creates excellent conditions for plants inside the building. The material perfectly passes the sun's rays, but for the same reason it is subject to rapid wear and, as a result, a decrease in light transmitting abilities. In addition, very often condensate forms on the inner surface, which can also be attributed to the disadvantages of this type of coating.There are also variants of polyethylene films, additionally equipped with reinforcement. This option is stronger, more resistant to gusts of wind and will last longer.

Glass can be safely attributed to the traditionally used materials in the manufacture of greenhouses with their own hands. Glass coatings are durable and have excellent thermal insulation, but remember that glass heats up very quickly and weighs quite a lot. A separate difficulty is the replacement of broken glass.

Polycarbonate is a sort of solid clear plastic., the structure is a material with large cells. It has sufficient impact resistance and light transmitting ability, is very flexible, and therefore suitable for the construction of greenhouses with arched vault or in the form of a tunnel. Since this type of coating consists of air-filled cells, it can be argued that it is the most thermally insulating among all possible options.

When considering this type of coverage for a potential greenhouse, consider also the following of its disadvantages:

- when exposed to sunlight, the material will inevitably collapse;

- during installation work, do not forget that polycarbonate tends to expand strongly when heated;

- in the absence of protective elements in the places of attachment of the honeycomb material quickly filled with dust or mold, which will cause the coating to become unusable.

When attaching, consider also the following features:

- Mount the material so that water can flow along the longitudinal strips from the inside;

- there is an ultraviolet filter on one side of the material - this side should be outside the greenhouse;

- mount polycarbonate on specialized self-tapping screws with a thermal washer on them, pre-drill holes in the sheets.

Also note the following rules:

- An extremely transparent polycarbonate is suitable as a covering material. Despite the large aesthetic appeal of color, it is much worse than the sun's rays, it is fraught with the greenhouse not fulfilling its direct purpose.

- Be sure to check the presence of a layer with a UV filter.

- Choose the layer thickness depending on the season in which the greenhouse will be used.In summer and autumn, sheet thickness should be about 10-15 mm, in winter - at least 15 mm. Also, this value directly correlates with the strength of the frame - the greater the thickness, the stronger should be the supporting structure.

- When joining sheets, use special profiles, the use of nails is absolutely unacceptable.

- Sheets should not be overlapped.

- Pay attention to the components and do not try to save on them - the use of end profile and end tapes will significantly prolong the durability of the greenhouse.

When choosing pay attention to the manufacturer. Do not forget that the miser pays twice, so it is better not to buy Chinese materials, despite their attractive price. Among the well-established in the market in recent years, we can mention the domestic company Kinplast. This company offers a range of different coatings - from low-cost to premium options.

Sheets of the Russian company Aktual will last about 8 years.

This is an inexpensive option, has a fairly soft structure, well mounted.

- The Russian-Israeli production Poligal Vostok offers a material that is characterized by rigidity, flexibility, ease of installation, but also has a high price tag.

- "Vinpul" is made in China, very soft, fragile, inexpensive, you can count on the service life of 3 years.

- “Sanex” is also a representative of the Chinese market, quite hard in work, not very convenient for installation, it will serve for about 4 years.

- "Marlon" brought to Russia from the UK, the material is quite expensive, but will serve if you follow the rules of operation for at least 10 years.

Since the market currently has a huge number of options, you can get confused and choose among them is not too high quality.

To avoid this, pay attention to the following points:

- The surface of the sheets should be uniform and smooth, not have any protrusions, irregularities and chips. Also, it should not break up into layers.

- The ribs must be at an angle of 90 degrees and in no case should there be undulations.

- Try to find out from the seller, under what conditions the material was stored. Improper storage conditions quickly reduce its useful life. Sheets should lie horizontally, but if they were stored in a vertical position with an emphasis on the edge or folded, this may reduce the quality of the material.

- Some summer residents prefer mixed type of covering materials.With this option, usually the side walls are glazed, and the ceiling is covered with a film. Some farmers prefer to cover the frame with spunbond cloths.

Separately, it is worth noting that in the same greenhouse it is not recommended to grow different types of crops at the same time - in other words, the same room is not suitable for seedlings and fruit and berry crops at home. This aspect must be considered when choosing the type of greenhouse. Arched greenhouses, occupying a wide area, will not bring great benefits. He considers the optimal size of a simple greenhouse to be 3 to 6 meters - it will not take up much space, you can easily grow enough strawberries, cucumbers or tomatoes in such a greenhouse.

Preparation of materials

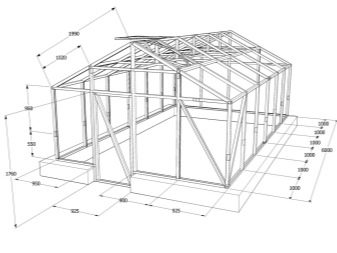

Before starting to work, carefully study the best projects and drawings from the resources made available to the public - this will allow you to see the most complete picture of the opportunities provided. Of course, you can create a scheme yourself, but remember that this will require not only the investment of additional temporary and energy resources. In addition, an error may creep in during the calculations, which may lead to the loss of its quality characteristics by the greenhouse.

If you present the scheme of performance of work on points, a general description of the stages of construction will look like this:

- determine the desired type of construction;

- preparation of the scheme;

- frame creation;

- carrying out preparatory work on the plot of soil where it is planned to install a greenhouse;

- foundation laying;

- mounting frame;

- mount translucent coating.

During the self-design or selection among the ready-made options, start from the requirements for the finished structure, as well as the available materials and preferences in the choice of crops. Most often in the backyards have arched structures with a frame made of PVC pipes - this is an inexpensive type of greenhouse, quite simple in execution. If a flat platform is chosen for the construction, it is best to focus on the model with two ramps. In the case where it is planned to put a greenhouse adjacent to the wall, it is more logical to make it lean. The base can be a geometric shape of various shapes - square or rectangle, trapezium.

Before purchasing the necessary materials for construction, it is necessary to make a calculation.This will help to prevent further expenses.

When the design has been completed and the greenhouse production scheme has been selected, it is necessary to start preparing the necessary components for the future construction.

If you take the simplest option that can be built in a couple of days, the set of materials will be as follows:

- Impregnated with antiseptic, treated with linseed oil or boards burnt with a blowtorch. Please note that if there is a desire to save money, you can not buy specialized tools, but use the time-tested old-fashioned methods of processing wood and timber. If the funds allow, of course, you can purchase factory chemicals.

- Polyvinyl chloride (PVC) pipes. Before making the frame, calculate the required amount of material for construction. After making the calculation, add 10% in reserve, especially if you have to do a pipe bender.

- Durable polyethylene film - the more resistant to wear will be the material, the longer it will not require replacement with a new one. Polycarbonate sheets can also be used if desired.

- Metal rods or pieces of fittings one meter long.

- Screws and nails.

- Hinges for mounting the vents and doors.

- Accessories - handles for doors and vents.

- Special loops for fastening pipes.

If it is decided to use HDPE pipes for forming the frame, consider the following features:

- Pipes contribute to the creation of tightness inside the building, which creates favorable conditions for the ripening of crops.

- This material is easy to use and does not require special skills.

- With the help of pipe fasteners, it is easy to assemble and dismantle if necessary Thus, the frame is easy to assemble for a warm climate period and again to remove when the greenhouse will not be used.

- There is no need to use additional reinforcement. The pipes themselves have good performance and are self-sufficient in use.

- Plastic, unlike wood or metal, is less affected by the environment. Finished products do not have to be treated with anti-corrosion and other protective substances.

- The building may well serve for at least a decade.

- Since the material has a low specific weight, the greenhouse can rock with strong gusts of wind.In this case, it is necessary to install additional metal elements in the ground to harden the structure.

Please note that in order to strengthen the foundation, you can use metal corners.they will give the construction strength. This element is mounted from the inside at the junction between the boards. If the base is made of timber, it is better to use for fastening metal brackets that are mounted on the outside. The finished foundation should fit snugly to the soil. If cracks appear, sprinkle them with earth.

Assembly and installation

When mounting the frame, metal fittings are driven into the ground from the outside into the ground at a distance of no more than a meter. Parts of plastic pipes that are pre-cut to the required length are placed on these blanks. To attach them to each other, as well as to mount them on a wooden base, use screws or nails, screws. To install the elements horizontally, as a rule, plastic couplings, angles and crosses pre-drilled from the inside, are used to enable pipes to cross connecting elements.

When polycarbonate sheets are used as cover material, the steps will be as follows:

- The protective film is removed from the sheets, the top side is marked with a marker. For convenience in the work better to make a few tags on each sheet.

- Make blanks for the end walls - for these purposes, a sheet of standard size is cut into three equal parts 2 by 2 meters. One of the parts is applied to the end in such a way that all the cavities are arranged vertically. The left side of the sheet is aligned to the left, the outline of the necessary arc is drawn with a marker. A similar manipulation is performed on the right edge, as a result of which the sheet acquires the contours of two semi-fuzzes. After that, they are cut with a jigsaw, leaving a tolerance of 3-5 cm, in the same way cut out the right end of the building.

- The cut parts are mounted on the screws at a distance of 30-50 cm from each other. Try not to pinch the material too much. Excess cut with a knife.

- The third part of the sheet is used for doors and vents. Sheet is vertically applied to the doorway. The contour of the door is outlined with a margin, blanks are cut out and attached.The remains are used to close the space above the door. Places joints better fasten special profiles.

- To close the top of the greenhouse, the sheets are stacked on the arc, aligned at the bottom edges and trimmed. Sheets should protrude slightly above the end of the building, then they are fixed in the corners.

- The second sheet overlaps the first at the junction, the corners are fixed and put on the screws from the bottom edge at a distance of 40-60 cm from each other.

In that case, if the greenhouse decided to cover the greenhouse with plastic wrap, the stages of work will be as follows:

- The film is attached to the frame with staples or wooden slats. Secure it in such a way that there are no tears in the canvas.

- It is necessary to cover the front and back parts of the frame with a film. In the part where it is planned to make the door, the film is bent inward.

- Re-measure the doorway, then you need to collect the frame from the tubes. The film is attached to the received frame, the excess is cut off and the door is hung with the help of hinges, window leaves are designed according to the same principle. If you are planning glass doors, carefully study the fasteners of glass to metal.

- This greenhouse option is only suitable for summer. The next and final stage after the construction of the greenhouse - soil preparation and planting of seedlings.

As mentioned above, for the winter version of the greenhouse it must be equipped with a heating system. With seeming complexity, it is not so difficult.

Among the types of heating are the following:

- solar;

- technical;

- biological.

Technical, in turn, is divided into the following subspecies:

- water;

- gas;

- stove;

- electric.

Solar type is based on the greenhouse effect, which is formed when natural light is entering the greenhouse space. This heating option is used only in summer when the sun is active. In the cold season, to achieve the best result, a mixed type is used - a biological-technological variant.

The species is used both in winter and in summer to heat the soil. Soil is removed from the shelves, after which manure is placed on the bottom, horse is best suited, since its decomposition produces a large amount of heat. Ground containers are filled with one-third manure.In addition to manure, you can also use compost - one of its components is also the product of the life activity of horses. Pour all the earth back into the racks. When the decomposition process begins, the roots of the plants will begin to warm up. In addition, it will serve as an excellent fertilizer, because manure and compost contain many minerals for plant growth.

The method of electric heating is also easy to use. For these purposes, a specially laid heating cable is used. Pre-read the instructions. Please note that the heat cable can be purchased with a temperature controller, so it will be quite easy to create the optimum temperature for the seedlings.

Water heating is arranged as follows: The entire perimeter of the greenhouse is laid double row of pipes, which are looped into the electric boiler. To connect the boiler, it is necessary to lay an electrical cable. Please note that the boiler can stand inside the greenhouse or can be moved to its limits. Experts insist that the boiler should be brought out and pre-insulated.These manipulations are done for the purpose of more uniform heating. You can also warm up the room using a heat source. The boiler is purchased directly from the store or you can make it yourself, however, please note that in the second case you cannot do without special knowledge and skills. Further, the procedure is similar - pipes are laid from the boiler under the racks which loop back. As fuel, you can use any solid fuel: coal, wood, waste woodworking production.

If gasification is present at your backyard, heating can be arranged by means of gas burners or heaters, for this purpose they must be placed around the perimeter of the building. With a small area of the greenhouse it is quite possible to use gas cylinders. If the greenhouse occupies a large area, then it is necessary to make a connection to the general gas system of the house. Gas burners create carbon dioxide, which is necessary for plants. In order to distribute heat evenly, fans are installed in the building. Burners can also be replaced by a gas factory boiler, but be sure to look at its country of manufacture.

Aluminum radiators or electric convectors are used as a source of heat in electric heating of the room.which are installed at an equal distance along the entire perimeter of the building or located on both its sides, if the area of the greenhouse has the shape of a rectangle. A system of this type is connected directly to the power supply or heating system.

You can also make an oven in a greenhouse that is best located at the end of the building. Horizontal chimney is laid from the stove around the perimeter of the greenhouse. For these purposes, suitable pipes made of metal or brickwork. When connecting the chimney and the vertical furnace riser, you need to make a small rise at the interface. The higher the riser, the better, because the stove will have good traction. With this type of heating do not forget to procure fuel in advance. You can put the oven in a pre-made recess in the ground.

In addition, from the usual furnace can be made water. For this purpose, it is installed on the boiler for water heating, from which the pipes will go to the tank with water. Pipes and boiler looped by wiring around the perimeter of the room.There is also another option - to assemble the pipes along each of the racks, thereby ensuring wiring to four different pipes.

We must not forget that plants require the creation of a special microclimate for their successful development and growth; special equipment will help to improve these indicators inside the greenhouse, with the help of which you can increase the productivity and productivity of the crops grown. Additional equipment requires not only additional heating, but also the possibility of ventilation, irrigation and lighting. As you know, watering plants is quite a laborious process. The automatic system will help save the owner of the dacha from this hard work, while saving time and water.

Good room ventilation is extremely important in a greenhouse., as it prevents the formation of condensate and improves the general microclimate, which undoubtedly benefits plants. Properly created air exchange will protect cultures from overheating. For the natural movement of air, it is enough to open the doors and air vents; an additionally installed fan or exhaust will increase air circulation.

With a short daylight, no sources of additional lighting can be done. Special lamps will help seedlings get enough light in early spring or late autumn.

Top projects

Be sure to check out the best and most common options, perhaps you will visit your own ideas.

For cucumbers

Separately, I would like to consider making a greenhouse for cucumbers as for one of the most beloved vegetables. Any summer resident knows that cucumbers need heat and high humidity. With proper organization of the protected ground, this vegetable is less susceptible to diseases and is able to give greater yield.

To obtain a rich harvest, the following requirements are necessary:

- daytime air temperature - not more than 30 degrees, night-time - not less than 16;

- soil temperature is about 23 degrees;

- calm air without drafts;

- about 80% humidity;

- high degree of illumination;

- insect access if the variety involves bee-pollinating;

- robust designs for vertical seedling movement.

Due to the large number of parts necessary climate is difficult to create in one room.Consider the common disadvantages and advantages of each type of greenhouses for a specific purpose - the cultivation of cucumbers.

The advantages include simplicity of design, ease of creation from scrap and existing materials. The small area and internal volume will provide good warming, it is well lit and easily accessible to insects for pollination. Among the minuses are such characteristics as a small planting density - you can arrange a maximum of three pieces per square meter, inconvenience in the processing of the soil and harvest. If you water the plants with a watering can, the water reaches the leaves, which can cause a burn. The greenhouse needs constant opening and closing, otherwise the cultures will overheat and die.

Arch type with film

The advantages of this type of greenhouse - it is simple to build and does not require expensive materials, has sufficient internal space for growing vertical bushes. Film coating retains moisture well, contributes to the rapid heating of the soil and air, perfectly transmits light. Disadvantages: the film is a short-lived material and requires regular replacement,has poor insulation performance, so in case of early frosts, the greenhouse will have to be covered additionally. When building a greenhouse of this type, it is necessary to have air vents, as when opening the doors inevitably there will be drafts.

Coated with polycarbonate

Pros: high structural strength of the frame, high ceilings and sufficient internal space. Polycarbonate perfectly transmits sunlight, has an excellent ability to disperse it. Provides convenient conditions for watering plants and tillage, easy to harvest. Provided vents provide good ventilation and the absence of drafts.

Cons: high financial costs for the purchase of materials or already finished products. Polycarbonate strongly reflects light, which is why energy is lost. The coating and frame require constant care, in winter it is necessary to clear snow from the greenhouse. Difficult access to pollinating insects.

Gabled with glazed wood frames

The advantages are as follows: a noteworthy design, which has already become a classic, demonstrates high thermal insulation properties.Good warming up of all internal space of the room. The glass has excellent light transmittance; when placing the vents on the roof, the possibility of drafts is excluded. The ability to plant a large number of plants, the availability of convenient access to them. Among the drawbacks it can be noted that the severity of the frame requires pre-laying the foundation. The tree requires mandatory prior and regular post-processing, otherwise the frames will quickly begin to rot. It is also worth noting that glass is a fragile and traumatic material, and also does not have any scattering properties, which can lead to burns of plant leaves.

With one ramp

Positive characteristics: it is attached to the house or shed always from the north side, which ensures that the slope turns south to obtain the maximum amount of sun rays. The room involves rapid warming and long-term retention of heat, and also gives room when choosing materials for construction. Negative characteristics: if the sun is active, it will be difficult to avoid overheating, need curtains and a high-quality ventilation system.If the greenhouse is built next to the house, it is imperative to have good waterproofing and protection of the greenhouse from snow and ice.

Mitleider

The undoubted advantage lies in the special arrangement of the vents - they are located in the roof and facing south, which leaves no possibility of drafts and contributes to the preservation of the optimum microclimate. The greenhouse is large, has high ceilings and plenty of space inside.

The disadvantages are associated with the complexity of the design and the inability to build it yourself, without having accurate drawings and installation skills. If the doors are closed, insects will not be able to get inside; either self-pollinated varieties will be suitable for such a greenhouse, or you will have to plant additional bait varieties. Among other things, the greenhouse requires close care.

In the shape of a pyramid

Pros: The central part is ideal for vertical cultivation of cucumbers. It is well lit, easy to install, only budget materials are needed.

Cons: small area, inconvenient to care for plants. Access insects difficult. The design is unstable and can easily be carried away by the wind.

For tomatoes

Polycarbonate greenhouses create ideal conditions for the harmonious ripening of fruits. Tomato refers to crops that love sunlight and heat, the optimum temperature for their cultivation is 22-25 degrees. If the soil has a high clay content, then humus, sawdust or peat should be added to the soil at the rate of one bucket per square meter.

Planted seedlings should be watered frequently until they are fully developed. In case it is cool enough at night, it is better not to water the plants after sunset, in order not to overcool the ground. Watering from a watering can makes sense during the hottest time of the season. Next, seedlings need to cut and tie up, thereby ensuring uniform illumination and ventilation of the beds. With this variant of cultivation, tomatoes ripen much faster and there is an opportunity to harvest a good harvest. After which the plants are attached to the wire grids or pegs, giving them space for further development.

For greens

In the cold winter, there is nothing better than a bunch of fresh greens, especially if it is grown with your own hands. What is especially nice, greenhouse greens are not too whimsical in care and gives several harvests a year. The greenery is quite possible to choose based on your own preferences.

Most people who use winter greenhouses for growing greens prefer dill, celery and parsley.

- When growing dill, it is necessary to strictly observe the temperature regime - the thermometer should not fall below 15 degrees. In addition, dill requires constant spraying and does not tolerate the presence of drafts and cold wind, so be extremely careful when airing the greenhouse. The first harvest can be obtained in two months with appropriate care.

- When growing parsley, there are several more nuances - firstly, this type of plant can be grown in the form of root crops or seeds. In the first variant, the root crop must first be kept in the sand, the temperature of which does not exceed two degrees, after which it is planted in highly moistened soil. If it is planned to grow parsley from seeds, seeds that are previously aged in moist tissue are planted in the soil. As a rule, the germination takes no more than ten days. The harvest is about one and a half kilograms of greenery per square meter.

- Celery likes well-fertilized soft soil, dung of cows or chickens is perfect as a fertilizer. The temperature in the greenhouse should be between 15 and 20 degrees.Watering for plants requires infrequent, but the most abundant, while it is necessary to ensure that the water does not touch the leaves of the seedlings. Pay special attention to the lighting, because the amount of the crop depends on the length of the daylight hours.

- Many people love mint very much and use it with pleasure when cooking. This type of plant tolerates frosts up to eight degrees of frost, while giving rise to sprouts at the lowest temperatures above zero. Experts recommend using hydroponics or biological soil heating with peat as soil. Carefully monitor the soil moisture, drying it is strictly unacceptable. If you plan to grow mint, it is best to equip a greenhouse with drip irrigation system.

- Mint, like most crops, does not tolerate temperature fluctuations not only because sudden jumps can destroy plants, such moments can lead to a dangerous disease - powdery mildew. Also for mint extremely dangerous pests are spider mites and the greenhouse whitefly. They can be defeated by spraying the culture with industrial means or popular recipes tried by time.

For a better planting of seeds in the soil, you must first dry them in a draft. If you can not plant seeds directly, it is possible to grow seedlings at home, followed by planting it in the ground for 10-14 days.

Not all gardeners have the time and desire to understand the intricacies of the technology of building a greenhouse on the site with their own hands. At the moment, the market is filled with ready-made greenhouses of various options. The first thing to do is to decide for what purpose the greenhouse is purchased. If we are talking about growing crops for family consumption, this is one thing, but if the gardener sees a greenhouse as a way to increase his income and wants to sell the resulting crop, the situation will be different. In the first case, you can get by with an inexpensive option, in the second, of course, financial investments will be much higher and the cost of maintaining the greenhouse will also increase.

Decide on the model, taking into account whether there is a willingness to install a stationary greenhouse or it is more logical to choose a collapsible option. Consider all the pros and cons - the stationary is installed once and no longer requires attention,collapsible same structure will have to assemble and disassemble twice a year.

How to make a greenhouse with your own hands, see the video.