Reinforced greenhouse: the best country options

Greenhouses have long become an integral part of the dacha plots in many regions of our country. The harsh climate does not allow to grow a full-fledged crop without additional shelter that maintains the optimum temperature for planting. For successful housekeeping a stationary, reliable and durable greenhouse is needed.

What it is?

A greenhouse is a structure made of a frame and a light-penetrating ceiling and walls. In Soviet times, with a general shortage, private greenhouses were built by summer residents themselves from scrap materials, wooden frame elements and glass or film for coating were used. Such greenhouses were most often impossible to even partially disassemble; in winter, snow and wind destroyed the fragile covering or broke the frame.Therefore, the gardeners every spring had to deal with the problem of restoring greenhouses, strengthening or repairing frames, replacing broken glasses or the complete tension of a new film sheet.

Over time, ready-made versions of greenhouses appeared on the market, consisting of a metal frame and a dense coating - polycarbonate. This material allowed the dome to be semi-circular, due to which the snow in winter does not accumulate on the roof in large volumes. This modification has solved many problems - now you don’t have to build a greenhouse yourself, and then worry about how it will endure the unpredictable Russian winter.

However, gardeners often began to encounter the unreliability of modern ready-made greenhouses. And the reason is the same climatic and weather conditions.

The cause of the problem and the solution

The fact is that the polycarbonate coating tends to maintain and maintain a constant temperature. This plus for summer time turns into a real problem in winter. The air temperature in the greenhouse and on the street does not fall at the same time, and even in severe frosts under polycarbonate it will be much higher. Falling snow rolls on the sloping surface is not completely, as it has time to melt and tightly held on the floor.With the arrival of spring, the problem intensifies - the sun's rays heat the snow crust, forming a rather heavy crust. Thus, even the metal frame can not withstand the forces of pressure and bend, breaking along with that and the icy coating.

Another reason is that strong winds are able to tear off parts of a poorly hardened greenhouse shell, and if the frame is made of a thin aluminum profile, then bend the base itself.

Solving these problems involves several budget options.

- Disassemble the greenhouse for the winter, in part or in full. This option is only suitable for collapsible designs. Additionally, you need to think about the storage space for fairly bulky parts of the building;

- Follow the snowfall and timely clean the snow from the greenhouse. This can create difficulties, even if the building is located on the site where you live all year round. Most often, greenhouses are installed in an open place at a distance from the house, and getting to them in winter through snowdrifts is sometimes quite problematic. To summer residents, who are leaving for the winter in the city, this option does not suit at all;

- Install in the building struts of solid wooden beams or reinforcement. Such a method does not always guarantee protection against destruction, but, if possible, will help preserve the frame from curvature.

The most optimal solution to the problem is to purchase a greenhouse with a reinforced frame or replace the base with your own hands for a more durable material.

Types of greenhouses

Before proceeding to the consideration of the features and differences of the strengthened greenhouses from the ordinary ones, let us examine the main types of these stationary structures. So, a greenhouse is a tall greenhouse, covered on all sides by a transparent coating. The height of the structure allows the gardener to move freely, work with plants, and also grow relatively high vegetable crops. In a greenhouse a favorable microclimate is formed, dense walls protect from drafts, frosts and heavy rain. The light-penetrating coating allows you to light a full light day culture, without interfering with the full absorption of ultraviolet radiation by plants.

In appearance, greenhouses can be:

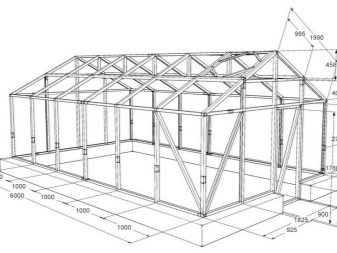

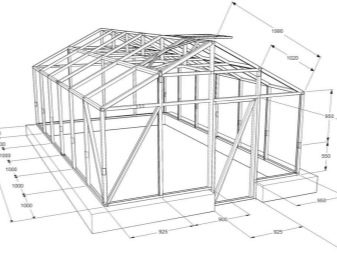

- A rectangular house with a gable roof;

- Rectangular with shed roof. Such buildings are an extension to something and have a significant drawback - the illumination with only onethe parties;

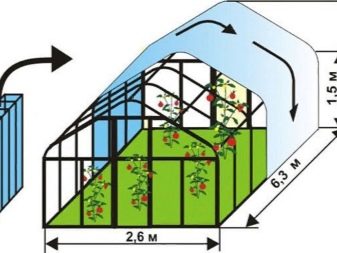

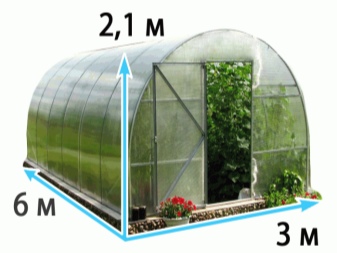

- Arched. It is a assembled frame of a certain number of high arches;

- Teardrop. The lancet form of the vault resembles a drop or a simplified Gothic structure;

- Dome. Hemispherical frame consists of segments of different geometric shapes. In appearance, such a greenhouse resembles a semicircular circus tent.

Materials

In the production and installation of greenhouses are used three main elements - the foundation, frame, coating.

Foundation

The greenhouse structure is not heavy and has no floor, so the foundation serves only to support the frame itself. This is an important point, as the greenhouse installed on the ground will be subject to distortions from winds, erosion or swelling of the soil. For reinforced greenhouses need a foundation on which the frame will be fixed very tightly. The type of foundation for greenhouses is tape, for its laying use concrete, bricks or wooden beam.

Frame

The frame is the main element of any greenhouse, as it must withstand the weight of the coating, the loads of precipitation and wind gusts. Frameworks are subdivided into wood and metal profiles.Wooden timber is prone to rotting and difficult to transport, so thin steel pipes of small diameter are used in the production of finished greenhouses. Stainless steel is more practical than wood, the material serves for many years, without being exposed to the damaging effects of soil, fungus and insects. For reinforced greenhouses, carefully select the diameter of the pipes and give preference to reliable galvanized arcs, crossbars and vertical beams. The steel pipe must be powder coated with a protective anti-corrosion compound.

Coating

The following materials can be used to cover the greenhouse:

- the film is polyethylene, reinforced or PVC;

- lutrasil;

- glass;

- cellular polycarbonate.

Today, greenhouse manufacturers prefer polycarbonateand there are reasons for this. The material is resistant to mechanical stress. It is convenient to work with him, he is easily cut and bends. Better than other materials retains heat inside the building. The porous structure allows you to create an optimal microclimate in the greenhouse. The strength and durability of the greenhouse depends on the quality and thickness of polycarbonate,therefore, when choosing, preference should be given to a material with a thickness of 4 to 6 mm, and its density should not be below 0.7 mm.

Dimensions and layout

The main parameters of the inner space are the width, length and height. From these indicators depends on the free growth of plants and the convenience of working in the garden. It is easier to work in a spacious greenhouse, there is no risk of accidentally damaging neighboring crops. However, it should be borne in mind that the access to the beds needs free access, but the land should not be empty, and the plants should not interfere with each other.

Width

When planning the width of the building, attention is paid to two main indicators - the width of the door (it should be comfortable to enter the greenhouse) and the width of the tracks (at least half a meter for a comfortable step and turn of a person). The rest of the space will be used as a bed. In order for plants not to be too crowded in an enclosed space, at least 75 cm on each side of the path should be left for their free growth. Thus, the smallest greenhouse should have a width of 2 meters. In this case, the best option is the structure of 3 x 6 m as the most comfortable for the growth of plants and land works.When planning and surveying, it is necessary to take into account that the width of the landings should not exceed 1.2 m in order to be able to freely reach the far edge of the bed without stepping on it. On the basis of these parameters, beds are formed in wider greenhouses, interspersed with tracks according to the same standards.

Length

The length of the greenhouse is an arbitrary parameter and depends on the wishes of the owner. The standard size is 4 m, where every 100 cm there is an arch arc. The sizes were not chosen randomly: 1 m is the size of a sheet of polycarbonate, and 4 m is enough space to create an optimal microclimate in a greenhouse. If desired, the length can be increased to 10 m, but the larger it is, the more difficult it is to maintain the desired temperature.

Height

The height of the structure depends on the height of the planned landings and the growth of the owner. Standard sizes are from 180 to 200 cm. This is sufficient for the free development of crops, running fresh air and human comfort. Too high arches of the greenhouse are unprofitable, more material will be spent on them, but the increased height of the roof will not bring any returns.

Installation process

The detailed instructions for self-installation are always attached to the factory product kit. Each model of the greenhouse has its own particular configuration and nuances of installation, so the instructions must be obtained along with the warranty card.

As a rule, a detailed description is enough to make an installation by hand without the involvement of specialists from the manufacturer.

Installation of the greenhouse is carried out at above zero temperature and already thawed soil. The frame is installed strictly on the pre-laid foundation, which will allow to avoid uneven pressing of the soil and subsequent damage to the frame and cover.

For the installation of any design will require a standard set of tools, consisting of a screwdriver, jigsaw, tape measure, construction level, a set of drill bits for metal.

Assembly sequence

At the first stage of the greenhouse assembly, the end parts are drawn up. Polycarbonate is attached to them with a solid sheet, protruding edges are neatly cut along the contour.

The second step is the installation of the lower base frame. The use of anchor bolts will most reliably protect the greenhouse from rocking under gusts of wind.

On the basis of installed end parts and arcs. At the top of the arcs fixed horizontal beam-ridge. During the installation of these elements, the bolts are not fully tightened, acting as holders of balance. The final tightening of the bolts occurs after the assembly of the entire frame.

The final stage of installation is the laying of the coating, the installation of end profiles and the connection with fastening edging. After which the greenhouse is ready for operation.

How to make a greenhouse with your own hands?

As an enhancement of the frame for the winter, you can use duplicate arcs or supports. Arcs are made of a metal bending profile, the diameter is less than the main frame. For beams used wooden beams, supporting the ridge of the roof and the main bearing crossbar. These works should be done in the fall, before the onset of the first cold weather, before the earth had time to freeze.

Useful tips

To enhance the existing greenhouses should be prevented design in the spring and autumn. Before planting and after harvesting, check the coating for damage, and the frame - for the presence of defects.These can be cracks on the film coating, corrosion in some areas of the metal base, or fungus, mold on wooden beams. Metal and wood should be well cleaned and coated with anti-bacterial or anti-corrosion compounds.

Periodic correction of minor damages will prevent a thorough destruction of the greenhouse, and will prolong its service life.

Manufacturers Overview

The main parameters by which consumers evaluate garden structures are strength, guaranteed service life, and the possibility of self-assembly of the product. Customer reviews on the gardeners' forums allow us to make a list of models of reinforced greenhouses made in Russia, to which gardeners assign the status of “the best”.

This line includes models:

- "Uralochka Reinforced";

- "Summer Resident";

- Kremlin Suite;

- "Garden of Eden";

- "Elbrus-Elite";

- "Orange";

- "Innovator";

- "Hope".

How to collect the strengthened greenhouse, you watch in video below.