Thermal insulation "Armor": types and characteristics of insulation

For high-quality repair work, manufacturers of building materials have been offering their customers thermal insulation for many years. Application in the production of innovative technologies and modern equipment made it possible to produce a new type of finishing material - ultra-thin thermal insulation “Armor”. The unique properties and technical characteristics of the domestic insulation “Armor” allow work to be carried out in accordance with European quality standards for insulating both horizontal and vertical surfaces.

Special features

Thermal insulation “Armor” is a Russian white ultra-thin insulating material that has no analogues in the world markets of building materials. An insulating coating with a liquid structure combines the properties of a heat-insulating material and a paint and varnish coating. It consists of binders from acrylic, catalysts, fixing elements, ceramic microspheres with rarefied air particles.

The addition of additional components to the solution helps to protect the metal from corrosion processes, and the concrete from mold and fungi.

The advantages of the material are as follows:

- used for insulation of all types of building surfaces, production equipment and pipelines;

- efficiency;

- possesses high rates of adhesion with surfaces from plastic, metal and propylene;

- protects the surface from the action of salt, sudden changes in temperature and the negative influence of the environment;

- reduces heat loss and has high heat protection performance;

- prevents the development of corrosion and condensation;

- used on structures of different shapes and configurations;

- has a small weight and eliminates the pressure on the supporting structures of the building;

- protects metal structures from damage due to sudden and frequent temperature changes;

- prevents the penetration of ultraviolet radiation;

- high speed of work;

- ease of work on the reconstruction of damaged areas;

- high refractory performance;

- environmental Safety;

- long period of operation;

- ease and high speed of work;

- low material consumption;

- resistance to chemical compounds of salts and alkalis;

- low level of explosion hazard;

- wide price range;

- small thickness of the applied layer;

- wide range of types of material;

- purchase ready-to-use solution.

Thermal insulation "Armor" has such disadvantages as:

- installation using a special airless processing unit;

- high price;

- work only at air temperatures above zero;

- long drying period;

- adding distilled water with a thick consistency.

Description

The heater "Armor" is a liquid heat-insulating material,forming an elastic dense polymer film. The structure of the material is similar to a simple paint with balls of glass or ceramic, filled with air. For high-quality application of thickened material, it must be diluted with water to the desired consistency.

The unique properties of the insulating material allow it to be used for insulation of various structures and objects, namely:

- industrial and civil structures made of metal;

- warehouse and garage buildings;

- heating systems;

- air conditioning elements;

- cold and hot water pipes;

- steam systems and parts of the heat exchanger;

- underground and surface elements of oil storage equipment;

- tanks for different purposes;

- refrigeration equipment and chambers;

- tanks for cars;

- railway and metro trains;

- cargo ship holds;

- door and window slopes.

Series

On the shelves of hardware stores you can find several types of ceramic liquid insulation.

- "Standard" - This is a basic type of material that has a low price. It is used to increase the insulation and waterproofing on surfaces of various types.

- "Classic" - it is a basic coating with high adhesive properties. It is suitable for all types of surfaces, has the smallest thickness.

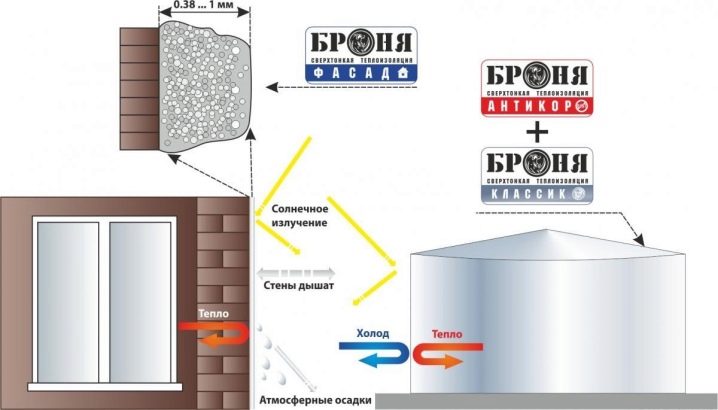

- "Antikor" - it is a versatile material that has high corrosion resistance. It is used to work on any surfaces, including rusty metal compressors.

- "Winter" - this is an insulating coating for work at low temperatures above minus 30 degrees.

- "Facade" it is applied to front works with drawing a layer 1 mm thick.

- "Light" - it is an advanced type of putty for construction and finishing works, allowing to insulate the surface of a different type and wide range of operation.

- "Fire protection" used in industrial and technical premises to improve the level of fire safety.

- "Universal" It has an affordable price, low consumption rate and universal purpose.

- "North" - it is economical material for work in the winter.

- "Metal" used for insulation of surfaces with different levels of corrosion.

- "Anti-condensate" - it is a universal type of coating for system insulation works.water supply and technical equipment with high humidity and condensation without additional treatment of the working surface.

How to choose?

When buying material for insulation, it is necessary to know exactly the type of planned work and the type of work surface, namely:

- for galvanized structures, Isollat insulation is suitable, which not only eliminates corrosion, but also prevents its appearance. The material should be applied only on the work surface treated with primer compositions;

- for hot water systems, an insulating type of material “Classic” is used. It makes it possible to cover the pipes several times, alternating layers with fiberglass;

- for work at low temperatures with a humidity of no more than 80 percent, winter insulation is often used;

- For the thermal insulation of facades used "Facade" and "Isollat", having the effect of washing off dirt and dust during the rain;

- To protect industrial premises and civil structures from high temperatures and fire they use the material “Fireproof”.

Positive feedback on this building material is left not only by builders., but also workers of different branches of production and repair organizations, such as:

- heat-insulating coating reduces the percentage of heat transfer, which allows repair services to eliminate hot water supply interruptions without shutting down the system, eliminate burns and avoid rapid cooling of water in the winter. The absence of condensate on the treated surfaces prolongs the life of the pipelines;

- the thick structure of the coating allows you to work on surfaces of different shapes, even in winter;

- the use of insulation in rooms with a small area allows you to maximize the free area of the building;

- the application of insulation on the roof of the house in several layers will not only protect the building from penetrating the winter cold, but also become an obstacle to the summer heat.

How to use?

It is very difficult even for experienced craftsmen to insulate constructions of large sizes and complex geometric shapes, to carry out outdoor work at low temperatures with ordinary materials. With the advent of liquid insulation on the shelves of building stores, it became possible to implement the most complex projects, filling all the cracks from the inside and chipped from the outside with a film no more than 30 mm thick.

Preparatory work is an important step in creating a strong, durable and reliable coating, consisting of the following procedures:

- cleaning the surface from the old coating and loose rust;

- treatment of the structure with special degreasing agents and solvents;

- working surface grinding with tools and hard brushes.

For the application of insulation professional builders use airless sprayers and soft paint brushes. The thickness of the layer should not exceed 1 mm. Coating in several layers allows economical use of construction material and create an effective thermal insulation protection. The temperature range must be individually selected depending on the type of working surface and the properties of the insulating material.

The principle of effective performance of work is to apply insulation with short strokes in a short period. Before applying the insulation, it must be thoroughly mixed and, if necessary, add the required amount of purified water. After applying all layers of coating and complete drying of the composition, the builders proceed to the final stage of work.Finishing the working surface is carried out with the use of different materials for the decoration, planned for the implementation of artistic and design solutions.

The unique building material makes it possible to warm the walls inside and outside the room.

Useful tips from the pros

Beginners should carefully study the recommendations of experienced builders who will help to perform work at a high professional level. Actual and popular advice for high-quality work are as follows:

- applying insulation to an uncleaned surface to significantly increase the percentage of consumption of building material;

- to obtain high rates of adhesion, the primer and insulation must be purchased in the same brand;

- when mixing a thick solution with distilled water, you must try not to damage the mixture microspheres;

- the volume of liquid when diluted should not exceed 5 percent;

- at high humidity in the room, the heater must not be diluted with liquid;

- to increase the level of thermal insulation, it is better to apply several thin layers of the coating than a thick one;

- the coating must be applied quickly and carefully;

- drawing the following layer is allowed only at full drying previous;

- performance of work in violation of technological norms and rules will result in low-quality coating and irrational use of building material.

Tips and recommendations of experienced builders will help you to perform the planned work qualitatively and quickly, taking into account the type of working surface and individual qualities of the material used.

For information about the characteristics of thermal insulation "Armor", see the following video: