Heat-insulating cylinders: features and purpose

Until recently, all pipelines had to be carefully insulated or buried below the ground freezing level. Such methods were time consuming, and the insulators did not last long. For the better, the situation has changed with the advent of insulating cylinders for pipes in the construction market.

What it is?

Heat-insulating cylinders are a heater for water and sewer systems, gas pipelines, heating systems, etc. From the name of the material it is clear that it has a cylindrical shape and performs the function of protecting steel and other metal, polyethylene pipes from freezing. It acts as a shell for pipes, preventing their heat loss.

Due to the fact that the cylinders are put on the pipe or its section directly during assembly, it is possible to achieve a tighter fit, and hence, higher rates of thermal efficiency.

The material is characterized by versatility of application and can be used both in civil and in the domestic sphere, for open and underground pipelines, as well as systems through which superheated liquid is transported (temperature reaches 600 ° С).

There are several types of cylinders, but all products of this type must meet the following requirements:

- low thermal conductivity;

- sound insulation characteristics, if we are talking about pipes of large diameter;

- weather resistance when it comes to systems on the surface of the earth;

- chemical inertness, resistance to aggressive effects;

- moisture resistance, vapor permeability, frost resistance.

Kinds

Consider the main species.

- Most heat insulating cylinders are made from mineral woolmainly stone. Rocks (gabbro and diabase), as well as additives (carbonate rocks) and a binder of organic origin are used as the basis.In their production, applied technologies are applied, that is, the layers are wound. This ensures uniform thermal conductivity across the entire surface of the pipe.

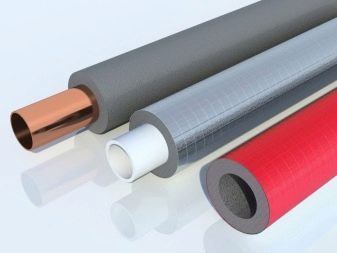

- Another type of cylinder are products polyethylene foam. Externally, they are pipes that have a longitudinal section on one side along the entire length. Standard length - 2000 mm, diameter ranges from 18 to 160 mm. It is the size of the diameter that underlies the classification of products of this type.

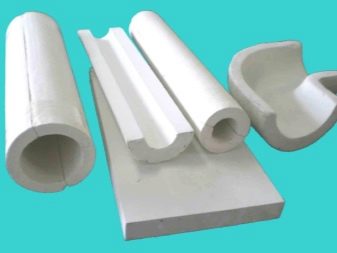

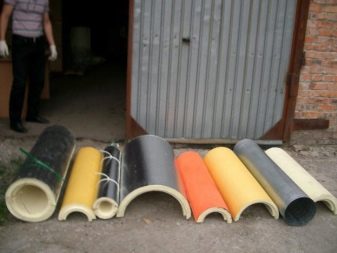

- Cylinders have a completely different appearance. polystyrene foam. They are semi-cylinders, called shells. Each of the halves has a spike and a groove, when installed, the halves are slightly offset, after which the locking mechanism is connected. Overall dimensions of polystyrene heaters: length - 2000 mm (sometimes there are products with a length of 1500 mm), diameter - from 32 to 530 mm, thickness - within 30-100 mm.

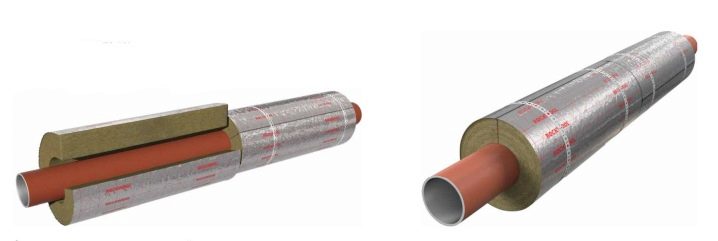

- Cylinders from polyurethane foam (PUF) - an example of insulation, which has the highest technical characteristics. They also look like cylinder halves, the outer side of which is equipped with paper, foil or fiberglass fiber.This provides not only the presentable appearance of the products, but also protects the surface of the PUF from the harmful rays of the sun, increases weather resistance. Polyurethane foam "shell" also has a length of 2000 mm, with a diameter of 32-1220 mm and a thickness of 30-60 mm. The tightness of the connection halves during installation is ensured by the presence of a fold and a groove on each of them.

- Finally, there are so-called perlitocement and ceramic insulation for pipes. They, like painting and priming compositions, are applied to the surface of the pipe. Such coatings on highly curved surfaces are especially in demand. In addition to heat efficiency, coatings demonstrate good adhesion, moisture resistance and weather resistance, low weight.

Depending on the presence of the outer layer, the cylinders are uncoated and coated. The latter can be an aluminum foil layer, a layer of glass cloth or galvanized protective covers.

Relatively recently, another type of coating appeared - the outside, which is a fiberglass mesh coated with a layer of foil.

Specifications

- In terms of their density, the cylinders correspond to thick stone wool mats. Specific gravity products ranges from 150-200 kg / m3. This provides the necessary rigidity of the material and strength to mechanical stress. It withstands a distributed load of up to 700 kg / m².

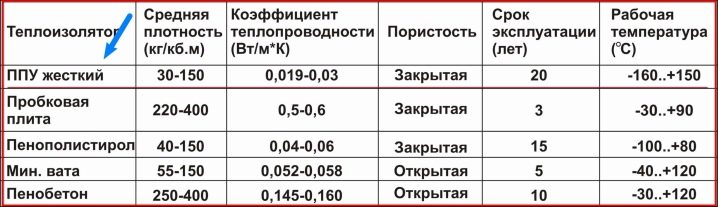

- Coefficient of thermal conductivity similar to the heat conductivity of mineral wool insulation and equal to 0.037-0.046 W / m * K. In addition to the insulating qualities, the cylinders are soundproof properties. The sound absorption coefficient reaches 95 dB (all products except polystyrene foam).

- The material does not trap moisture between the surface of the pipe and the insulation due to high vapor permeability (0.25 mg / m² * h * Pa). The resulting condensate is removed outside the insulation, which protects pipes from corrosion and mold due to high humidity.

- Certificate of Compliance indicates that water absorption cylinders should be 1%. Moisture on the surface is not absorbed by the material, but literally settles by drops on its surface. High moisture resistance, in turn, ensures that the coating is resistant to low temperatures.Mineral wool insulation is more susceptible to moisture. Any insulant, soaking, loses its insulating properties. In this regard, when using cylinders from mineral wool, it is necessary to take care of a high-quality waterproofing layer. Roofing material can be wound over the cylinder, bituminous mastic can be applied or a waterproofing membrane can be fixed.

- Another advantage - fire safety cylinders for pipes made of mineral wool, polyethylene foam and polyurethane foam. The material is considered non-combustible (NG) or has class G1 (low-combustible materials), if we are talking about products that are laminated with aluminum foil. Depending on the type, polystyrene foam insulation has a class of indicators from G1 to G4 (slightly combustible - highly combustible).

- Cylinders differ in weather resistance and resistance to high and low temperatures. For example, the thermal range of operation of mineral wool cylinders is -190 ... + 700 ° С, which makes them the best option for thermal insulation of heating pipes and chimneys. But analogs of foamed polystyrene are not suitable for heating pipes, since the temperature of their use is -110 ... + 85 ° С.If it is necessary to use them on pipes whose temperature exceeds 85 ° C, a 3-centimeter layer of mineral wool insulation is first wound onto them, and then the “shell” is fixed.

Dimensions

The dimensions of the cylinders are determined by their diameter. So, products made of expanded polyethylene, the diameter of which starts from 18 mm and ends at 160 mm, have the smallest dimensions. Mineral-cotton counterparts may also have a small diameter of –18 mm. However, the range of internal diameter in such products is wider - the maximum diameter is 1020 mm.

Foam polystyrene and polyurethane foam cylinders are characterized by slightly larger sizes. Their minimum internal diameter is 32 mm. The maximum dimensions of the diameter of PPU cylinders exceed the same values of polystyrene analogs.

Minor dimensional changes are found within the range of individual manufacturers. In addition, almost all of them (especially Russian trademarks) offer the manufacture of cylinders to order according to the size of the customer.

Accessories

A set of cylinders, in addition to a pipe (or "shell"), includes various elements,which allow to isolate such difficult sections of the pipe as inset, transitions, bends. For insulation bends and turns of pipelines apply bends. Tees allow to insulate joints horizontally and vertically oriented systems.

For more reliable fixation and snug fit, clamps are used. Edge compression pipe is provided by the use of plugs.

Manufacturers Overview

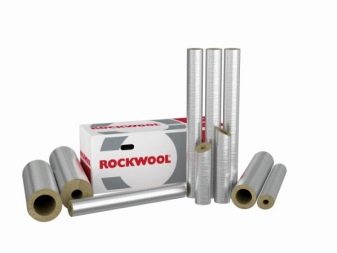

- It enjoys the confidence of customers and receives good reviews of specialists to date, brand products Knauf, URSA, Rockwool, ISOVER. Despite the higher cost compared to the materials of some other brands, these heat insulators are in great demand. This is due to the fact that the products fully comply with the declared technical characteristics, has an attractive appearance of finished products, is distinguished by safety and the availability of all components, which ensures simple and quick installation.

- Among domestic manufacturers, whose products are not inferior in their properties to European counterparts, but have a lower cost, emit "TechnoNIKOL", "Isofate".

- Leading position among manufacturers of insulation for pipes made of polyethylene foam takes the company "Energoflex".

- Among foam-polystyrene cylinders, products of the brand are in demand. "YEW".

How to choose and calculate?

Each type of cylinder has its own scope of application. In other words, when choosing a product, it is necessary first of all to evaluate its operating conditions.

- So, mineral wool insulation are considered the most vulnerable - they must be protected from moisture and environmental factors. However, with proper installation, they exhibit low thermal conductivity, non-inflammability and biostability.

- Cylinders polyethylene foam will be used to isolate pipes of small diameter. However, due to their instability to mechanical damage, it is better to apply them inside residential buildings.

- Polystyrene foam Cylinders or segments are heat-efficient, water-resistant and durable, however they are attractive to rodents and belong to combustible materials that are subject to fires and support combustion. In addition, they have a small thermal range of operation and cannot be used to insulate hot pipes.water supply systems through which heated liquids circulate.

- Versatile and truly reliable is the option from PPU. It has a long service life, is non-combustible, has a low coefficient of heat insulation, provides sound absorption. Polyurethane foam "shells" do not become food or home to rodents.

For joints, you should purchase construction tape (with internal thermal insulation) or foil tape with an adhesive base (if work is being done on the street).

For calculation it is necessary to take into account the area of the pipe, the conditions of its operation and the material of manufacture, the thickness of the insulation. It is more convenient to make calculations using special formulas.

Recommendations for use

Regardless of the type of cylinders, it is recommended to observe the following rules for their operation and installation, which will extend the term of maintenance-free use of products.

- Thermal insulation and pouring of polyurethane foam of street pipes should be carried out only in dry weather. It is unacceptable to cover wet pipes with a cylinder, as this will negatively affect the condition of the insulation.

- Metal tubes require prior staining.It is better to use priming or powder coloring compositions for this.

What features need to be considered when insulating pipes in the house, you can learn from the following video.