Paint-insulation: description and specifications

Paint-insulation is a modern material that has recently gained increasing popularity. Liquid insulation, although it can not be a full replacement for conventional insulation materials, but also has certain advantages. Description and technical characteristics of the composition will be discussed in more detail in this article.

Special features

Paint-insulation is primarily intended to create a heat-insulating coating, so quite often this material is called liquid insulation.The composition refers to the dye mixtures because of the method of its application to the surface, which resembles the process of painting.

Insulating paint is made on the basis of water or acrylic.

Ceramic microspheres with a diameter of 0.01 millimeter, which contain a vacuum inside, are responsible for the thermal insulation properties. Instead of ceramic balls, the paint may also include silicone analogues with a diameter of 0.02 millimeter. It is the vacuum that retains heat and does not allow it to pass through the layer of paint and varnish.

The main task, which is solved with the help of paint-insulation, is to reduce heat loss. The consistency of the mixture is quite thick, which allows you to apply it on almost any surface. In apartments and private houses, the material also performs an energy-saving function, as it allows to reduce heating costs, and in the case of using electric heaters, it also saves electricity.

Properties

As mentioned earlier, the main property of the insulating composition is to retain heat. However, some paint modifications may differ in certain specifications.For example, some manufacturers produce a composition that not only has the characteristics of insulation, but also prevents the accumulation of moisture on the treated surface.

This property is especially important for metals, which allows you to protect the material from corrosive formations.

If we talk about the technical characteristics of the material, then depending on the composition and manufacturer, they may differ. The main properties of paint-insulants include the following:

- A lacquer coating layer equal to 1 millimeter is equivalent to a 50-millimeter layer of thermal insulation from products of mineral origin. In certain cases, the paint may well replace conventional insulation.

- The heat-insulating coating created does not attract moisture.

- Through a layer of insulating composition deposited on the surface, there is a slight loss of heat, which can be 5%. This property provides evaporation of moisture from the coating, which in turn prevents freezing of the treated structure.

- The paint is a mass of gray or white, which has a pasty consistency.

- The service life of the formed insulation coating can be from 12 to 40 years.

- The operating temperature range is usually from -70 to +260 degrees.

Advantages and disadvantages

Like all building materials, nano-paint-insulation has its advantages and disadvantages. Among the advantages of this composition are the following features:

- The mixture is easily and simply applied to almost any surface.

- The paint can be used for thermal insulation, even in those places where conventional insulation can not be used.

- The paintwork is not subject to rotting.

- Thermal insulating composition does not apply to combustible materials.

- Paint-insulation does not emit toxic substances in the air, so it is absolutely safe for health.

- There is a high level of adhesion to most materials.

- The coating protects the substrate against condensation.

- There is a high level of resistance to alkaline and saline solutions.

- There is resistance to direct sunlight and weathering.

- Does not create an additional load on the surface.

- In the case of peeling or cracking of the coating, it is possible to easily and quicklyrestore the integrity of the paint layer.

- Thanks to this coating, the temperature in the building can be higher by 4 degrees.

- The composition is not afraid of direct contact with water and has anti-corrosion properties.

- There is a good resistance to mechanical stress.

Despite significant advantages, paint insulation also has several disadvantages. Highlight the main disadvantages of such coverage:

- Before applying the composition of the base should be well prepared: cleaned, degreased and completely dried.

- To insulate the exterior walls of the paintwork will not be enough. It is recommended to use paint together with other heat-insulating materials.

- When applied to uneven substrates, the flow rate of the mixture can be quite large.

- High-quality paintwork material has a rather high cost.

Kinds

All paint-insulation can be divided in composition and purpose. Based on the composition of the material, there are the following groups:

- water based blends;

- blends based on acrylic.

In addition to water or acrylic base, the paint contains additional components,which are responsible for the technical characteristics of the coating and its purpose. If we take into account the scope for which the composition is intended, then We can distinguish the following types of paint-insulants:

- Mixtures for indoor use. Such compositions are intended for processing walls, floors and ceilings.

- Compositions for heating radiators, as well as gas and water pipes. Such mixtures are characterized by a high level of resistance to high temperatures and water-repellent properties.

- Paint for outdoor work has a good resistance to weathering and temperature extremes.

Scope of application

Insulating paint is used in many areas and is suitable for processing virtually any material. The composition not only reduces heat loss, but also protects materials from negative environmental factors. By preventing the formation of condensation and repelling moisture, a protective layer of paint applied to the wood protects it from rotting. For metals, compositions with anti-corrosion properties are available.

Most often, the paint-insulation is used for painting the following objects:

- internal walls of apartments, private houses, industrial and administrative buildings;

- facades of buildings and roofing;

- concrete floors of basements and cellars;

- window slopes;

- wooden door slopes;

- storage tanks for liquids;

- cold and hot water supply;

- brickwork seams;

- engineering communications pipes;

- car body;

- foundation of the house;

- metal structures and facilities.

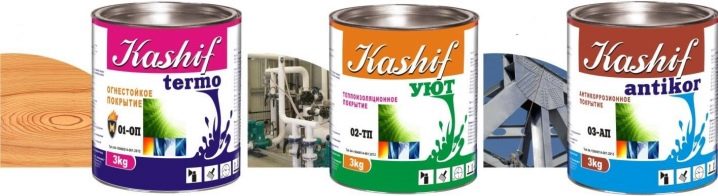

Manufacturers

Before buying a warming paint, it is important to choose the right composition. It is necessary to focus not only on the technical characteristics of the mixture, but also on the manufacturer, since the quality of the coating will depend on this.

"Innovative technologies"

The Russian company "Innovative Technologies" specializes in the development and manufacture of high-quality modern materials for repair and construction. The main goal in the development of high-tech compositions is to provide various structures with the proper level of protection from the negative impact of the external environment and increase their service life. In the production process, only quality raw materials from global manufacturers are used.

Among the products of the company "Innovative Technologies" there is a separate line of insulating paints, which is produced under the brand Re-Therm. Liquid insulation Re-Therm has unique technical characteristics and reduces the cost of heat energy when the layer is 1 millimeter thick. The composition not only reduces the level of heat loss, but can also be used as a waterproofing coating.

Ultra-thin Re-Therm insulation is available in several versions, each of which has its own purpose.

It is worth noting that all products manufactured under this brand have a lot of positive customer reviews. Buyers note that Re-Therm blends meet the stated requirements and perfectly fulfill their thermal insulation functions.

The disadvantages of such coverage include its high cost.

"Armor"

Scientific and Production Association "Bronya" is another leader in the Russian market for the production and sale of insulation materials. Under the brand "Bronya" a separate line of liquid thermal insulation is produced, which also has a large assortment of mixtures for various purposes.Choose the right composition for any task and the material does not present much difficulty.

Paint-insulation "Armor" in many technical indicators exceeds both domestic and foreign counterparts. The coating can be operated at temperatures from -60 to +250 degrees, and its service life will be at least 15 years.

Tips and tricks

- When choosing the right composition it is necessary to carefully study its purpose and technical characteristics. For example, mixtures designed for indoor use outside buildings will not provide an adequate level of protection against heat loss and the negative impact of the external environment.

- Before applying the composition to the surface, the substrate must be free from dirt and grease.. It is most convenient to apply the mixture with a sprayer on large areas. Hard to reach places must be painted with a paint brush.

- Operating temperature range each modification of paintwork material may have its own, therefore, before starting work, carefully study the instructions for the product. Water-based mixtures are usually allowed to be applied at air temperature not lower than 7 degrees.Some acrylic compositions for facade works can be carried out staining at low temperatures not lower than -20 degrees.

- Warming paintwork the material is usually applied in no more than three layerswhile the thickness of one layer must be at least 0.4 millimeter. The mixture is applied quite easily, leaving no streaks on the surface. In those cases when it is necessary to paint concrete or brick foundations, it is recommended to first treat them with a priming deep penetrating mixture.

The principle of the paint-insulation, see the following video.