Sprayed insulation: what is it and where is it used?

The process of building insulation is constantly being improved and often accompanied by the use of the most efficient and new technologies and more promising building materials than those that everyone is used to using. And now another type of high-quality insulation has appeared on the market, which is sprayed onto the surface of a certain area. These materials have already taken the lead among the best thermal insulators.

Features and composition

Sprayed insulation is called heat-insulating raw materials (in fact, an analogue of polyurethane foam in cans), which is applied to the surface by spraying using special equipment.

This substance consists of two liquid products that, when mixed, can form a huge amount of foam, which is intended to cover a substantial area for its insulation.

The main component of the sprayed insulation is polyurethane foam. This material is a special mixture consisting of two components, which are polyols polyol and isocyanate.

- Component A is a hydroxyl-containing substance, it is necessary to maintain the reaction with component B. It is a solution of a saturated yellowish or dark brown color, in which various polyesters can be found with catalysts, foam regulators, fire retardants and foaming agents.

- Component B - isocyanate is a dark brown substance that is in a liquid state, with a specific chemical smell. If the component begins to actively interact with the atmosphere, solid polyurethane begins to form in the process, which will be completely unsuitable for use. It is for this reason that its supplies are carried out in hermetically sealed containers, which reliably protect the components from contact with liquid or air (in cans).

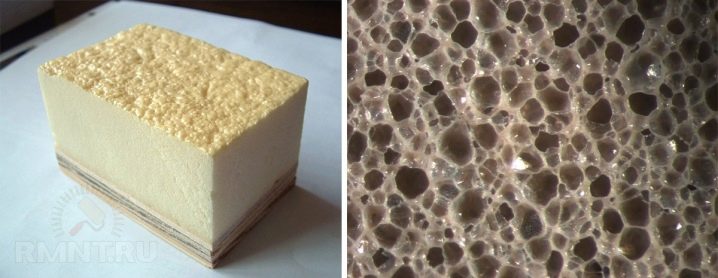

When mixed, the components A and B enter into an active interaction, with a huge amount of carbon dioxide released, which helps the material to foam well.After hardening, polyurethane forms a layer of insulation, which consists of a large number of small, hermetically sealed cells, which are completely filled with carbon dioxide.

Due to this, the material has a lower coefficient of thermal conductivity, therefore, ideal for insulation.

Specifications

The sprayed insulation material is fairly lightweight and can be applied to the surface of any material without any significant problems with a layer of any thickness. Sprayable insulation is well known to all professionals and novice craftsmen who value this practical material for Its unique characteristics are:

- The highest thermal conductivity was observed in these materials, and it is approximately 0,020-0,028 W / ms. In more modern materials, this indicator will be much lower, which makes their purchase less desirable for the consumer.

- Excellent sound insulation performance. This category of insulators will successfully reduce even strong percussion noises that prevent sleep and rest in the most comfortable conditions. Thus, complete silence will be ensured in any room during the work of special tools, which are distinguished by high noise efficiency.

- The vapor permeability of sprayed insulators will allow them to simply absorb moisture, while not allowing a large amount of condensate to form, which can ruin the coating.

- The use of this innovative material allows us to insulate even those places that were previously considered difficult to access - all thanks to its unique consistency.

- Adhesion parameters, which are typical for this thermal insulating material, will allow you to quickly insulate the surface of any materials.

- It is possible to determine the deadlines for the construction work with this insulation - for insulation of 100-120 m2 it is enough 9-10 hours at the lowest labor cost of this process.

- In the characteristics of the insulation of the sprayed type, excellent resistance to various kinds of biological organisms and chemical reagents is also noted.

- The resulting coating will last for a very long time and will not suffer from constant exposure to various precipitations typical for the zone, aggressive atmosphere of various industrial production, various pests and microorganisms (however, the material is afraid of prolonged exposure to sunlight, which must be considered when working with it).

- PPU with a density of 70 kg / cu. mThe material practically does not pass water and quite often it is used as a waterproofing.

- Experts do not refer this material to the class of non-combustible (NG), however, because of the flame retardant A component, it was awarded a special certificate of fire-fighting type G2. The material itself does not burn well, and its composition will only contribute to the rapid self-extinguishing of an open flame due to the timely release of carbon dioxide from the cells.

- Approximate consumption of insulation - 890 ml per 1 m2 with a layer thickness of 5 mm.

Advantages and disadvantages

This material can become an excellent barrier for unproductive heat losses in the winter period and will help to save on air conditioning in the summer months. Due to good heat preserving qualities, only a very small layer of foam needs to be sprayed, therefore PU foam is ideal for arranging internal thermal insulation. Besides, sprayed material has many more positive qualities:

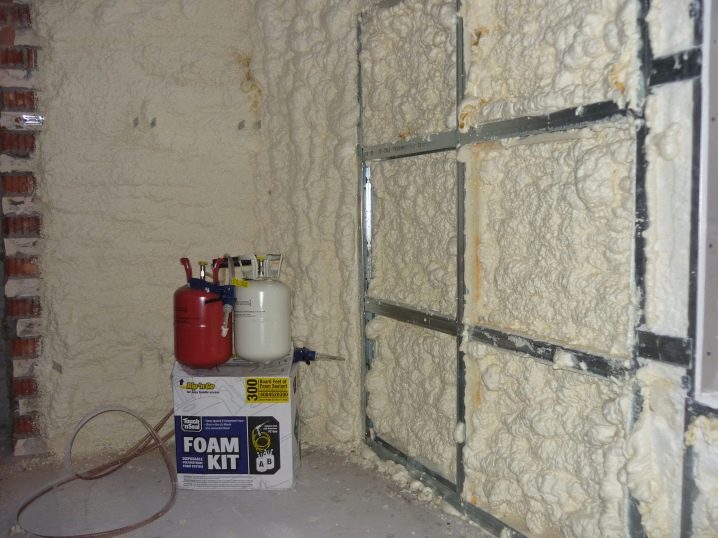

- Sprayed insulation, as the name implies, is applied by spraying a ready-to-use mixture of special equipment in the form of a gun that connects to a compressor. It is for this reason that after polymerization the material forms a completely seamless layer which eliminates the appearance of cold bridges at the joints and where the foam will be adjacent to the functional elements of the structure.

- Due to the fact that, while freezing, the foam from polymers does not absorb water at all, it can easily withstand many successive cycles of freezing and thawing without destroying its own internal structure. In addition, insulation well tolerate the effects of many external factorswhich other materials fear. The only exception is UV radiation. At observance of all existing rules of installation the warming layer keeps the technical characteristics during at least 50 years.

- Spray-applied heat insulator qualitatively adjacent to all known building materialsFor example, to a rather smooth drywall and even metal. However, they must first be prepared with high quality, completely cleaned of dust, remove garbage from them and remove various grease stains.

- For installation of insulation no need to use brackets, adhesives or cratethat will significantly save your construction budget.The batten, if installed, is only for fixing the outer material of the decor, which can be lining, siding or drywall. Therefore, even the most inexperienced master will be able to cope with this kind of installation without difficulty.

- After polymerization, the foam becomes so strong that even able to transfer very significant external mechanical effects. It can be used to insulate the foundations of buildings and their basements, which are partially buried in the ground. In the process of backfilling and active operation, the sprayed insulation is not damaged, which is also an excellent characteristic.

But without the minuses, too, was not done:

- The final cost of one square meter of insulation will turn out to be much higher than when using already known and customary heaters - foam plastic or mineral wool. However, the rather high technical characteristics of the new material could well justify the substantial amounts invested in the insulation of the house.

- The need to use special equipment. For spraying a significant layer or amount of foam, a compressor and a special type of device are used, where the two elements are mixed.All these devices will need to be purchased or, if you need to insulate only your dwelling, to rent equipment. And it will also bring not the smallest costs.

- The need for various means of protection. The material itself after solidification is considered completely safe for humans, but during the foaming process it will release harmful chemical elements, so you need to work using a respirator. And in order to protect the skin from sticking foam (which will then be very difficult to clean), you must purchase overalls or other special clothing.

- Low UV resistance. The structure of the material will quickly decay when the foam is irradiated with UV rays. Therefore, the heat-insulating layer should always be protected from the outside with decorative finishing materials - cement plaster, durable siding, panels.

Application

By reason of compliance with safety standards, sprayed insulation can be used for arranging both public and residential buildings. The area of its use is quite universal, which is not surprising:

- roofing and garret designs of various types and forms;

- warming of floors in premises and different institutions and establishments;

- insulation of walls of various premises.

Depending on the purpose of the objects of application, we can offer the following classification:

- industrial building;

- all sorts of farm building;

- refrigeration equipment;

- pipeline mains;

- various technological tanks.

Many owners of their own cottages, and even apartments, all the construction work on the house they want to do with their own hands when possible. But in this case it can be difficult to do this without some preparation and important equipment.

In any case, for warming with polyurethane foam with their own hands You will need to use special equipment and components necessary for this operation, namely:

- polyol, which must be mixed in a balloon container with freon;

- isocyanate, mixed with freon 134.

These cylinders must be filled so that the pressure in them is at least 8 atm. After the surface has been processed and prepared, the spraying itself is done - you need to gently activate the spray gun, directing the foamy stream of insulation to the place you need.Since the independent application process is not as complicated as the preparatory measures, it will be more convenient to choose the insulation in cylinders. In addition, they are almost the same. Sprayed insulation in cylinders is considered to be much more convenient, since it has competently executed industrial training, including the necessary pressure regime.

Application technology

Polyurethane foam is often chosen for treating the roof system from the inside, so it can be used not only during the construction of the dwelling, but after the complete completion of all work from the attic. After solidification, the foam not only warms the space under the roof, but also creates a high-quality noise absorbing barrier, and also strengthens the entire roof structure. The heat insulator applied by spraying is conveniently used for thermal insulation of attic walls, which usually have a complex shape with a huge number of uneven joints and hard-to-reach places. Typically, the insulation of the room can take up to several hours, after which you can enjoy plenty of comfortable warmth in the winter and pleasant coolness in the summer.

If you choose insulation for walls, then you need to know that you can apply it on exterior walls as well as on internal surfaces. In addition to the insulation itself, the treatment helps to protect the structural elements of the building from the effects of rain, wind loads, temperature fluctuations and other destructive factors.

The material can be perfectly applied to horizontal surfaces, and only a small layer is necessary for good insulation, therefore the distance from the floor to the ceiling will not significantly decrease.

The technology of applying the material is not too complicated:

- surfaces need to be cleaned from dust and dirt, and also made a little wet;

- on the cylinder you need to install a special nozzle;

- the balloon must be gently shaken, then also gently direct the nozzle to the area that is insulated;

- by clicking on the trigger of the gun, the material is dispensed by a sprayer.

Manufacturers and reviews

To date, the following sprayed heaters can be called very popular:

- Polynor - it is a heater based on polyurethane foam, which was developed jointly by several well-known construction companies.The Polynor tool has only the best consumer reviews as the best of all modern materials, which is ideal for thermal and sound insulation. In addition, the scope of its application is wide enough, it opens up considerable opportunities for high-quality insulation.

- "Ecotermix" - it is sprayed insulation, which is made on the basis of vegetable oils, it contains a minimum amount of harmful substances. On sale there are two of its varieties: 300 grades - with a closed structure to protect the external surfaces from cold, and 600 grades - with an open structure for interior work. Thus, you have the opportunity to choose the material for a particular type of work.

- Sealection 500 - American-made material. It has an open structure and class of fire safety G2. It is also very popular, although it has a decent cost.

- Healtok Soy 200 - insulation with a closed structure, is made from soybean oil cultures and various wastes from the number of polymers. It adheres perfectly to any possible surfaces, fills all cracks and pores on walls and floors with high quality.

- Sprayed polyurethane insulation Teplis - this is an excellent solution in topical issues of insulation of open spaces, hard-to-reach places and communications, roof, foundation of the building. Teplis can be successfully used even by a person who does not have special skills. Spraying is done with a mounting gun. Insulation speed 1 m2 in 2-3 minutes.

- Heater Penoplex fastfix may be applied to any surface, including vertical, as well as surfaces with a negative slope. Ideal for small spaces. It can also be used as an auxiliary heater for application to uneven and geometrically irregular surfaces, as well as places where it is technologically difficult to use sheet insulation.

Of course, there are other companies that manufacture insulation, but insulation from these manufacturers is most in demand.

You will learn even more interesting information about the sprayed heater in the next video.