Penoplex with a density of 35: characteristics and scope

When creating a project at home, future owners pay much attention to planning, exterior and interior decoration, in other words, creating coziness. But a comfortable life without heat will not work, therefore, the choice of thermal insulation materials is treated very carefully. Increasingly, customers are using Penoplex products to preserve heat in their homes.

Material Features

Unfairly executed insulation contributes to the freezing of walls, the destruction of the facade, entering into the premises of pathogens, fungi and mold. And just the loss of heat (up to 45%) due to poor insulation of the walls, floor, roof will not please anyone.This means that the life of the building, its reliability and appearance, and the microclimate of the interior are largely dependent on the choice of appropriate materials.

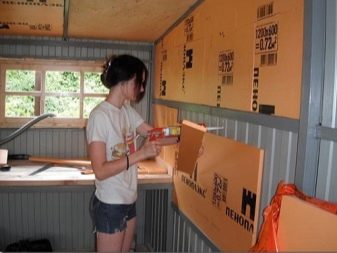

Before a company appeared in St. Petersburg that started the production of polystyrene foam boards, Russian developers had to use heat-insulating materials from foreign manufacturers. This significantly increased the cost of construction. The first production line in Russia for the production of penoplex was launched 19 years ago in the city of Kirishi, and its products immediately began to be in great demand, since at a comparable quality with foreign brands, the price decreased and delivery times were reduced. Now branded orange plates can be seen on many construction sites.

Immediately it should be noted that both the material and the company are correctly called Penoplex. But since the sound combination with “e” is inconvenient for the Russian language, the name of the product — penoplex — was fixed everywhere.

Depending on the purpose, several types of plates are produced today:

- Penoplex Roofing - for warming roofs;

- Penoplex Foundation - for thermal insulation of foundations, floors, basements and basements;

- Penoplex Wall - for insulation of external walls, internal partitions, facades;

- Penoplex (Universal) - for thermal insulation of any structural elements of houses and apartments, including loggias and balconies.

Penoplex 35 is the predecessor of two series of materials: Penoplex Roofing and Penoplex Foundation. The first is less flammable due to the introduction of the flame retardant with the additive patented by the manufacturer.

Composition

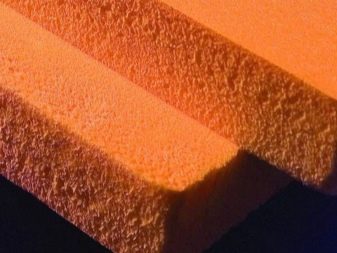

Penoplex is produced by extruding foam. Environmentally friendly CO2 reagent is currently used for this process, raw materials are also safe. It contains no formaldehyde and other harmful substances, does not contain dust and fine fibers. As a result of extrusion, a cellular structure of foamed polystyrene is created, that is, the material consists of small bubbles, but it turns out to be uniform and durable.

Technical properties

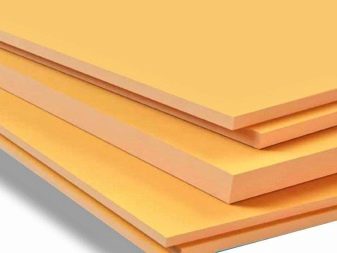

Penoplex 35 got its name because its average density is 28-35 kg / m3.The main indicator of thermal insulation materials is thermal conductivity. This value for extruded polystyrene foam is extremely low - 0.028-0.032 W / m * K. For comparison, the heat transfer coefficient of air, the lowest in nature, at 0 degrees Celsius is about 0.0243 W / m * K. Due to this, to obtain a comparable effect, a layer of penoplex 1.5 times thinner than another heat insulation material is required.

Other technical characteristics can also be attributed to the merits of this material:

- lightweight, penoplex is quite strong - 0.4 MPa;

- compressive strength - more than 20 tons per 1 m2;

- frost resistance and heat resistance - withstand temperature range: -50 - +75 degrees Celsius;

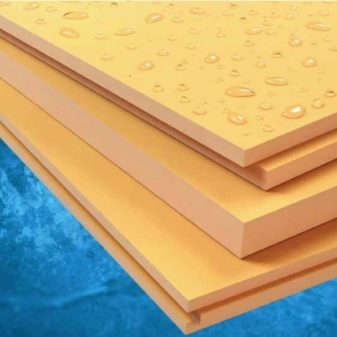

- water absorption - 0.4% of the volume per month, about 0.1% per day, at sub-zero temperatures, when inside the dew point, condensate does not form;

- vapor permeability - 0.007-0.008 mg / m * h * Pa;

- additional insulation - up to 41 dB.

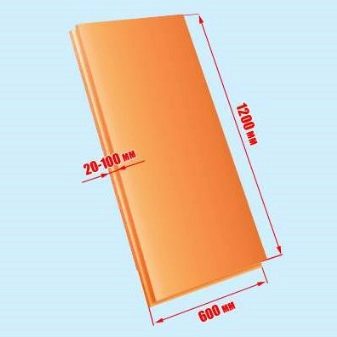

Standard dimensions of the plates: length - 1200 mm, width - 600 mm, thickness - 20-100 mm.

Advantages and disadvantages

All the listed parameters are equally relevant to Penoplex Foundation and Penoplex Roofing materials. They differ in such quality as flammability. The certificates of conformity often indicate classes G2 and G1.As practice shows, it would be more correct to attribute the Penoplex Foundation to the G4 group, Penoplex Roofing - to the G3. But this is enough to consider such plates as fire-resistant material.

Special additives, flame retardants, prevent the development of the combustion process and the spread of flame. The material complies with fire safety standards GOST 30244-94.

According to ST SEV 2437-80, penoplex refers to heat insulators that do not spread a flame when burning, which is difficult to burn, but with high smoke generation. This is one of the few cons. Although smoke is not poisonous. During combustion, carbon dioxide and carbon monoxide are mainly released. That is a smoldering penoplex is not more dangerous than a burning tree.

In addition to the advantages described, it is necessary to note the resistance of materials of this brand to rotting and the formation of mold, unattractiveness to rodents. Another important quality is the ability to withstand several cycles of freezing and thawing, while retaining its characteristics and, most importantly, its insulating properties. Thanks to these features, Penoplex 35 can effectively serve for over 50 years.

Since the heat insulation retains heat in the house, does not allow moisture to pass outside, then the air exchange will be difficult, so you need to take care of good ventilation. The disadvantages can also be attributed to a fairly high price. But when choosing a different, cheaper heater, for example, a wadded one, it is necessary to take into account that such a material readily absorbs moisture, often shrinks, forming cold areas, is less durable, repair may soon be necessary. Therefore, in the end, it may turn out that such a “thrifty” customer will also overpay.

Scope of application

Brand names speak for themselves. "Penoplex Foundation" can be used for thermal insulation of the floor, vertical insulation of the foundation, as well as under the sole, ground floors, basements, laying garden paths. Roof plates are used on roofs of any configuration, including inversion roofs, on which the layers of the "cake" are stacked in reverse order. In this case, penoplex put on a waterproofing layer.

In road construction, with warming warehouses, hangars, industrial facilities used more dense "Penopleks 45".

Due to its moisture resistance, the plates do not require additional external vapor barrier. The need for an insulating layer from the inside occurs when partitions of a material with a higher vapor permeability, for example, aerated concrete (0.11-0.26 mg / m * h * Pa), are insulated. A vapor barrier from the side of the room can serve as polyethylene and liquid glass.

Installation Tips

When warming the floor layers are stacked in the following order:

- layer, leveling the surface, for example, crushed stone with sand;

- Penoplex Foundation plates;

- vapor barrier material;

- screed;

- adhesive composition;

- coating, exterior finish.

When a warm floor is laid, the thickness of the structure will be significantly less than when using another thermal insulator. And an important factor is energy saving.

When warming the roof, an external vapor barrier is also not needed, and the internal one is placed under the penoplex.

On the sloping roof of the slab stacked in a checkerboard pattern to hide the rafters. Secured with slats with nails. It should be noted that the roofing penoplex at the edges has a L-shaped edge, which makes it possible to join the sheets tightly, avoiding gaps and gaps.

More about the vertical weatherization.

- To achieve a snug fit of thermal insulation plates to the surface of the foundation, it must be prepared. Everything should be thoroughly cleaned from old coatings, if any. Paint, varnish is removed with solvents or mechanically using tools.

- To eliminate the possibility of fungus and mold, you can treat the surface with a bactericidal or fungicidal composition. Existing salt deposits are mechanically cleaned.

- The angle of deflection on the foundation is adjusted using a plumb line or level. Now the surface needs to be leveled. This can be done with suitable plaster. After drying, primed with a finishing compound. Such processing will not have any significant effect on the properties of the thermal insulator, it will only improve adhesion.

There is another way to improve the fit of the insulation. It is possible to make plates to order, taking into account the surface bends. To do this, make a map of irregularities and penoplex make a certain thickness in specific places.

Metallic elements should be coated with anti-rust paint compounds.If you carry out plastering, then further work can begin about a month. Plates are mounted on glue, additionally fixed with dowels. Next - a protective layer or metal mesh for plaster and exterior finish.

The installation process is simple. Plates "Penopleks 35" due to the strength and ease of easy to use. They do not crumble, they can be cut with a simple knife. It does not require masks and other protective equipment.

It can be concluded that Penoplex is a universal energy-efficient thermal insulation material that reliably retains the heat of your home.

Learn how to determine the density of the foam, learn from the following video.