Penoplex 50 mm thick: properties and characteristics

In winter, up to 50% of heat is lost through the ceilings and walls of the house. To reduce heating costs install insulation. Installation of insulation reduces heat loss, allowing you to save on utility bills. A popular material for thermal insulation of residential structures is penoplex of various thickness, in particular, 50 mm.

Features: pros and cons

Heat-insulating material penopleks is made of polystyrene by extrusion. In the production of polystyrene granules melted at a temperature of up to +1400 degrees. A foaming catalyst is introduced into the mixture, which enters into a chemical reaction with the formation of oxygen. The mass increases in volume, filling with gases.

In the manufacturing process, synthetic additives are introduced to improve the properties of the heat insulator.The addition of tetrabromoparaxylene provides self-extinguishing in case of fire, other fillers and stabilizers protect against ultraviolet radiation and oxidation, impart antistatic qualities to the finished product.

Polystyrene foam composition under pressure enters the extruder chamber, where it is molded into blocks and cut into plates with a thickness of 50 mm. The resulting stove contains more than 95% of gases enclosed in polystyrene cells no larger than 0.2 mm in size.

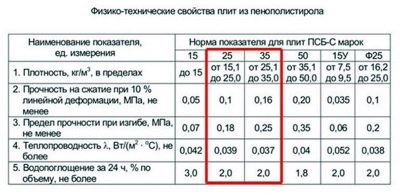

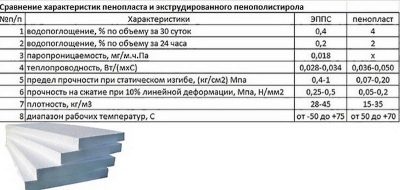

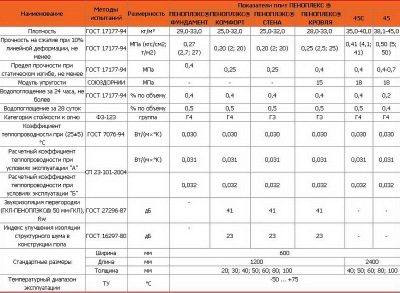

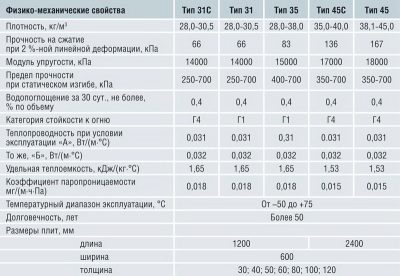

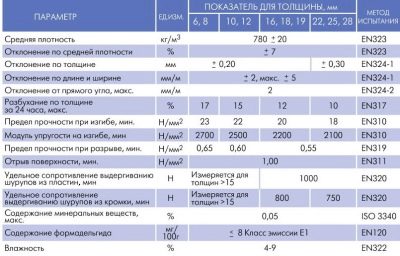

Due to the peculiarities of the raw material and fine-meshed structure, extruded polystyrene foam exhibits the following technical characteristics:

- thermal conductivity varies slightly depending on the moisture content of the material from 0.030 to 0.032 W / m * K;

- vapor permeability is 0.007 Mg / m * h * Pa;

- water absorption does not exceed 0.5% of the total;

- insulation density varies depending on the destination from 25 to 38 kg / m³;

- compressive strength varies depending on the density of the product from 0.18 to 0.27 MPa, the limit bending - 0.4 MPa;

- fire resistance class G3 and G4 in accordance with GOST 30244, refers to normal and highly combustible materials with a temperature of smoke emitted 450 degrees;

- Flammability class B2 in accordance with GOST 30402, moderately flammable material;

- flame spreading over the surface in the FP1 group does not spread fire;

- with high smoke-forming ability under the D3 group;

- material thickness 50 mm has an airborne sound insulation index up to 41 dB;

- temperature conditions of use - from -50 to +75 degrees;

- biologically inert;

- does not collapse under the action of building solutions, alkalis, freon, butane, ammonia, alcohol and water-based paints, animal and vegetable fats, organic and inorganic acids;

- susceptible to destruction when gasoline, diesel, kerosene, tar, formalin, diethyl alcohol, acetate solvent, formaldehyde, toluene, acetone, xylene, ether, oil-based paint, epoxy resin hit the surface;

- Duration of operation - up to 50 years.

- Resistant to mechanical damage. The higher the density, the stronger the product. The material breaks with effort, does not crumble, slightly perminates. The combination of characteristics allows to insulate with this material both the objects under construction and the buildings that need to be reconstructed and repaired.The material properties determine the positive side when using penoplex 50 mm thick.

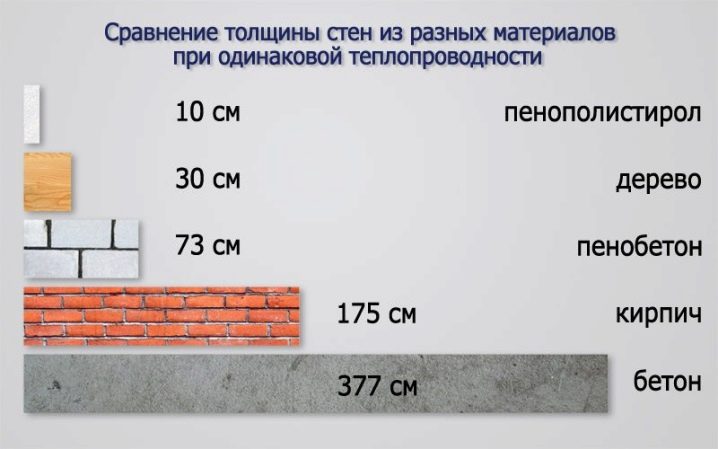

- The thickness of the insulating layer is small in comparison with other heaters. Thermal insulation of 50 mm extruded polystyrene foam is equivalent to 80-90 mm of a layer of mineral wool insulation and 70 mm of foam plastic.

- Water-repellent qualities do not allow to maintain the growth of fungi and bacteria, which meets sanitary and hygienic requirements, showing biological resistance of the insulator.

- Does not cause a chemical reaction when in contact with alkaline and salt solutions, building mixtures.

- High level of environmental safety. During production and operation no harmful substances are released that can adversely affect the environment and human health. You can work with insulation without personal protective equipment.

- Fast payback of a heat insulator due to the acceptable cost and economy on heat carriers.

- Ability to self-extinguish, does not support and does not extend burning.

- Frost resistance to -50 degrees can withstand 90 cycles of temperature and humidity effects, which corresponds to the level of durability of 50 years of operation.

- Unsuitable for living and breeding of ants and other insects.

- Low weight facilitates transportation, storage and installation.

- Quick and easy installation thanks to dimensions and locking connections.

- Wide range of applications and versatility. Approved for use in residential, public, industrial, agricultural buildings and structures.

- The material is not resistant to fire, emits acrid smoke during decay. The outer side can be plastered so that there is no direct contact with the flame. So the group of combustibility rises to G1 - slightly combustible substances.

Any construction and insulation material has negative points during operation. They need to be considered during installation and reduce the risks of thermal insulation of structures. Among the shortcomings of Penoplex are several characteristics.

- Chemical solvents can destroy the upper layer of the material.

- Low vapor permeability leads to the formation of condensate on a warming base. Therefore, the walls need to be warmed outside the premises, leaving a ventilation gap.

- Acquires brittleness with prolonged exposure to ultraviolet radiation. To avoid detrimental effects, penoplex should be protected from the sun by conducting exterior trim.This may be a plaster, a ventilated or wet facade system.

- Low adhesion with various surfaces provides for fixation on facade dowels or specialized adhesives.

- Material may be damaged by rodents. To protect the heat insulator, which is in the open access for mice, use a metal grid with 5 mm cells.

Sheet dimensions

Penoplex dimensions are standardized and easy to install. The width of the sheet is 60 cm, length - 120 cm. The thickness of the insulation in 50 mm allows to provide the required level of insulation in temperate climates.

The calculation of the number of squares required for insulation is made in advance, taking into account the area of the structure.

Penoplex comes in a plastic shrink film. The number of pieces in one pack depends on the type of material. The package of a universal heat insulator contains 7 sheets of 0.23 m3 in volume, allowing it to cover an area of 4.85 m2. In a penoplex package for walls - 8 pieces of 0.28 m3, with an area of 5.55 m2. Package weight varies from 8.2 to 9.5 kg and depends on the density of the insulator.

Scope of application

Insulation in the house should be comprehensive in order to achieve effective reduction of heat loss.Since up to 35% of heat goes through the walls of the house, and up to 25% through the roof, the insulation of wall and attic structures should be carried out with suitable heat insulators. Also, up to 15% of heat is lost through the floor, therefore, the insulation of the basement and the foundation will not only reduce heat loss, but also protect it from destruction under the influence of ground movement and soil erosion by groundwater.

Penoplex 50 mm thick is used in the individual and professional construction industry.

Types of insulation are divided by the scope of application in thermal insulation work. In low-rise buildings and private apartments use several series of penoplex.

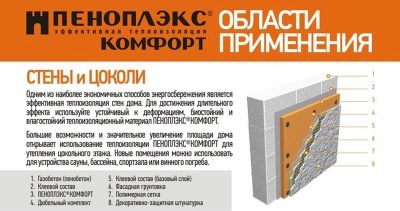

- "Comfort" with a density of 26 kg / m3. Designed for warming cottages, villas, baths and private houses. Comfort plates isolate walls, plinths, floors, floors, attics, roofing. The apartment is used to expand the area and get rid of the dampness on the loggias and balconies. In the countryside construction is suitable for the device of the landscape gardening zone. Thermal insulation of the soil under the garden paths and garage areas will allow to avoid deformation of the finishing coating.These are universal plates with a strength of 15 t / m2, 20 m2 of insulation are contained in one cube.

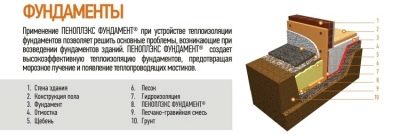

- "Foundation"whose density is 30 kg / m3. It is used in private housing construction in loaded structures - traditional, tape and low-depth foundations, basements, blind areas, basements. The boards are capable of withstanding a load of 27 tons per square meter. Protect the soil from freezing and groundwater flow. Suitable for thermal insulation of garden paths, drains, drainage channels, septic tanks and pipelines.

- "Wall" average density of 26 kg / m3. It is installed on internal and external walls, partitions. According to thermal conductivity, a 50 mm insulation replaces a 930 mm thick wall of bricks. A single sheet covers an area of 0.7 m2, increasing the speed of installation. The grooves on the edges remove cold bridges that go deep into the surface of the walls and shift the dew point. Ideal to use for facades with further finishing decoration. The milled rough surface of the plates helps to increase adhesion to plaster and adhesive mixtures.

In professional construction, the size of the plates can vary, they are cut into lengths of 120 and 240 cm. For thermal insulation of apartment buildings, industrial, commercial, public facilities, sports and industrial facilities use the following brands of foam panels.

- «45» characterized by a density of 45 kg / m3, increased strength, can withstand a load of 50 t / m2. Designed for use in road construction - laying of roads and railways, reconstruction of city streets, the device embankments. Insulation of roads helps to reduce the consumption of building materials, the cost of repairing the roadway, increases its service life. The use of Penoplex 45 as a thermally insulating layer in the reconstruction and expansion of the runway of the airfield allows to reduce the deformation of the coating on heaving soils.

- "Geo" designed for a load of 30 t / m2. Density of 30 kg / m3 allows to warm the foundation, plinth, floors and operated roofs. Penoplex protects and warms the monolithic foundation of a multi-storey building. It is also included in the structure of the slab foundation of small burial with the laying of internal engineering communications. It is used for laying floors on the ground in residential and commercial premises,in industrial refrigerators, on ice arenas and skating rinks, for the foundation of fountains and the arrangement of a pool bowl.

- "Roof" Density of 30 kg / m3 is designed for thermal insulation of any roofing structures ranging from a pitched roof, ending with a flat roof. Durability in 25 t / m2 allows installation on inversion roofs. These roofs can be used as parking or green areas. Also for the insulation of flat roofs developed brand of foam plastic "Slope", which allows for water flow. Plates are created with a slope of 1.7% to 3.5%.

- "The foundation" medium strength and density of 24 kg / m3 is an analogue of the Comfort series, intended for universal insulation of any structures in civil and industrial construction. It is used for external insulation of walls in multi-storey buildings, internal insulation of basements, filling of expansion joints, in creating door and window lintels, for erecting multi-layer walls. Laminated masonry consists of an internal load-bearing wall, a foam layer and an external brick or tile finish. This masonry reduces the thickness of the walls by 3 times compared with the requirements of building codes to a wall of a homogeneous material.

- "Facade" A density of 28 kg / m3 is used for thermal insulation of walls, partitions and facades, including the first and basement floors. The milled surface of the plates simplifies and shortens the plastering work on the finishing of the facade.

Installation Tips

A guarantee of the effectiveness of thermal insulation is the observance of all stages and rules of installation work.

- Before installing penoplex, it is necessary to prepare the surface on which the material will be laid. Heterogeneous plane with cracks and dents need to close up the plaster mixture. If rubbish, loose elements and remnants of the old finish are present, the interfering parts are removed.

- When traces of mold and moss are found, the affected area is cleaned and treated with an antiseptic fungicide mixture. To improve adhesion with the adhesive composition, the surface is treated with a primer.

- Penoplex is a rigid rigid thermoplastic, which is mounted on flat surfaces. Therefore, measure the level of evenness. If the difference exceeds 2 cm, then alignment is required. The technology of installation of heat insulators differs slightly depending on the surface design - for the roof,walls or floors.

- Installation of insulation can be carried out at any time of the year, but more comfortable if the temperature is above +5 degrees. For fixing the plates use special adhesive compositions based on cement, bitumen, polyurethane or polymers. As an additional fasteners used front mushroom dowels with a polymer rod.

- Installation on the walls is carried out by the horizontal method of placing the plates. Before installing the penoplex, you need to place the starting bar so that the insulation is in the same plane and the rows do not move. On the lower bar will rest the bottom row of insulation. The heat insulator is attached to the glue in a staggered manner with a combination of grooves. The adhesive composition can be applied in strips of 30 cm or in a continuous layer. Be sure to glue the connecting edges of the panels.

- Then they drill holes to a depth of 8 cm. 4-5 dowels are enough for one sheet of foam plastic. Install dowels with rods, caps should be in the same plane with insulation. The final step will be the decorative finish of the facade.

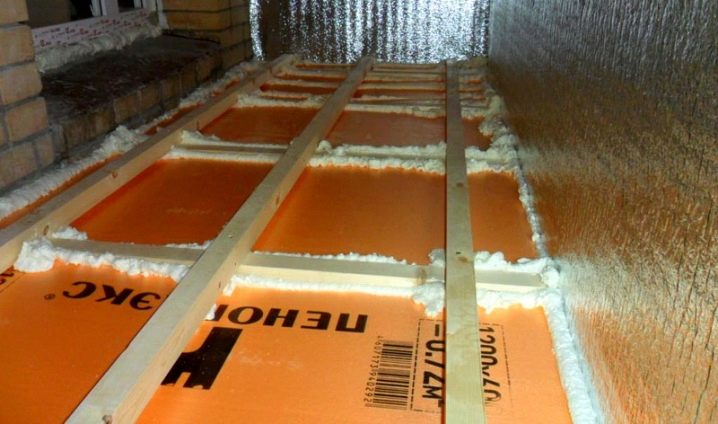

- When the floor is being warmed, a penoplex is laid on the reinforced concrete floor slab or prepared soil and fixed with glue.A waterproofing film is laid on which a cement screed is made with a thin layer. After complete drying, you can install a finishing floor covering.

- For the thermal insulation of the roof, the penoplex can be laid on the attic floors above or below the rafters. When building a new roof or repairing the roof covering, the heat insulator is installed on top of the truss system. Joints are glued with glue. Longitudinal and transverse slats with a thickness of 2-3 cm with a step of 0.5 m are attached to the insulation, forming a frame on which the roof tiles are mounted.

- Additional insulation of the roof is carried out inside the attic or attic room. On the rafters mount the frame sheathing, which is placed penoplex, fixing dowels. A counterbribe with a gap of up to 4 cm is installed on top. A layer of vapor barrier is applied with a further covering by finishing panels.

- When insulating foundations, you can use the technology of permanent formwork from the foam panels. For this purpose, the formwork skeleton is assembled using a universal screed and reinforcement. After the foundation gulf, concrete insulation remains in the ground.

An overview of the comparison of penoplex with other materials, see the following video.