Styrofoam: dimensions and features of the application

The production method of expanded polystyrene was patented in the late 20s of the last century, having undergone multiple upgrades since then. Expanded polystyrene, characterized by low thermal conductivity and light weight, has found the widest application in many areas of industrial activity, in everyday life and as a finishing building material.

How is polystyrene foam different from foam?

Styrofoam is a product of gas injection into the mass of polystyrene. This mass of the polymer with further heating increases significantly in its volume and fills the entire mold. Different gases can be used to create the required volume, which depends on the type of foam polystyrene produced. For simple heaters with standard properties use air,injected to fill the cavities in the mass of polystyrene, and to impart fire resistance to certain grades of PPP used carbon dioxide.

When creating this polymer can also be involved in various kinds of additional components in the form of flame retardants, plasticizing compounds and dyes.

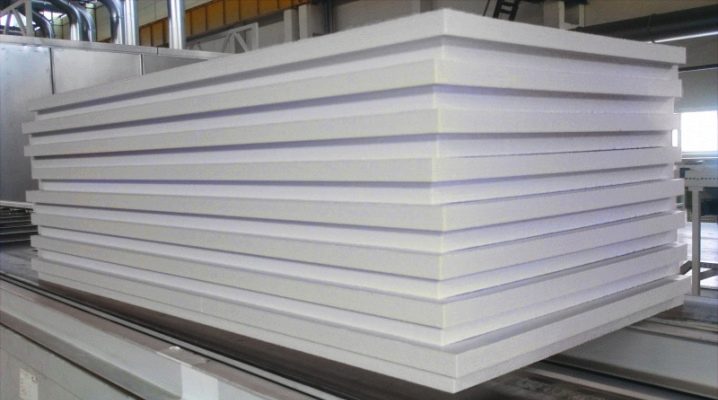

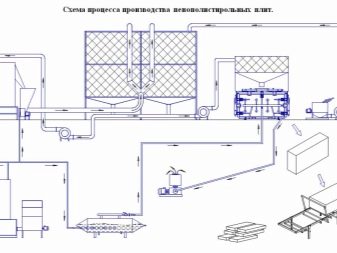

The beginning of the process of obtaining a heat insulator comes from the moment of filling the individual granules of styrene with gas, followed by dissolving this mixture in the bulk of the polymer. Then this mass is subjected to heating with steam of a low boiling liquid. As a result, the size of styrene granules increases, they fill the space, huddling together. As a result, the material thus obtained is cut into plates of the required size, and they can be used in construction.

Styrofoam is usually confused with foam, but it is completely different materials. The fact is that polystyrene foam is a product of extrusion, which consists in melting polystyrene granules and binding these granules at the molecular level. The essence of the process of manufacturing foam is the connection of polystyrene granules with each other as a result of polymer processing with dry steam.

Technological methods and release form

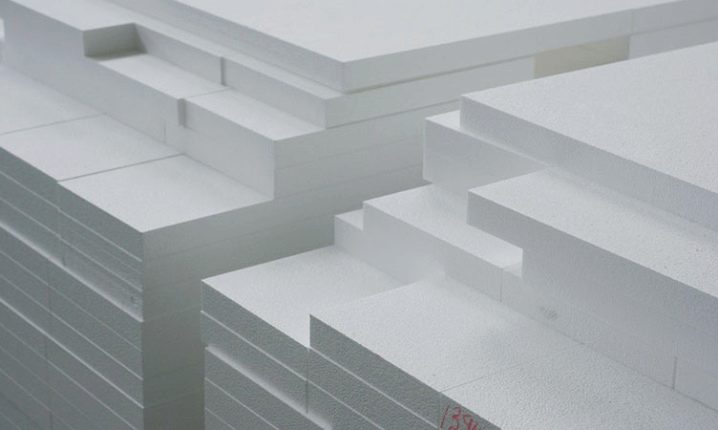

It is accepted to distinguish three types of expanded polystyrene with its unique properties, which are caused by the method of manufacturing a specific insulation.

The first is the polymer produced by the bespressovy method. The structure of this material is replete with pores and granules of 5 mm - 10 mm. This type of insulation is characterized by a high level of moisture absorption. On sale there is a material of brands: C-15, C-25 and so on. The figure indicated in the marking of the material indicates its density.

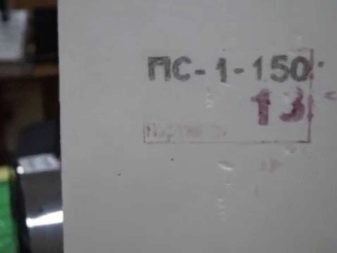

Styrofoam, obtained by manufacturing under pressure, is a material with hermetically sealed internal pores. Due to this, such a pressed heat insulator has good thermal insulation qualities, high density and mechanical strength. Mark is denoted by the letters PS.

Extruded polystyrene foam is the third type of polymer. Having the designation of EPPS, it is structurally similar to extruded materials, but its pores have a much smaller size, not exceeding 0.2 mm. This heater is most often used in construction.The material has a different density, which is indicated on the package, for example, EPPS 25, EPPS 30 and so on.

Foreign autoclave and autoclave-extrusion types of insulation are also known. Due to the very expensive production, they are rarely used in domestic construction.

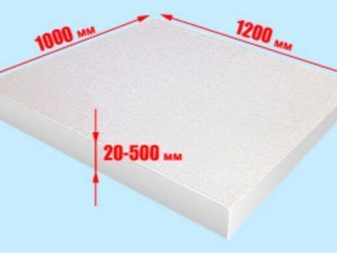

The dimensions of a sheet of this material, whose thickness is of the order of 20 mm, 50 mm, 100 mm, as well as 30 and 40 mm, are 1000x1000, 1000x1200, 2000x1000 and 2000x1200 millimeters. Based on these indicators, the consumer can choose a block of PPP sheets both for insulating fairly large surfaces, for example, as a substrate for laminate flooring for a warm floor, and for relatively small heat-insulated areas.

Styrofoam properties

The density and other technical parameters of this material due to the technology of its production.

Among them in the first place is its thermal conductivity, thanks to which polystyrene foam is so popular insulating material. The presence of gas bubbles in its structure serves as a factor in the safety of the indoor microclimate. The coefficient of thermal conductivity of this material is 0.028 - 0.034 W / (m K).The thermal conductivity of this heater will be the higher, the greater its density.

Another useful property of PPP is its vapor permeability, the indicator of which for its different grades ranges between 0.019 and 0.015 mg / m • h • Pa. This parameter is above zero, because the sheets of insulation are subjected to cutting, therefore, air can penetrate through the cuts into the thickness of the material.

The moisture permeability of polystyrene foam is almost zero, that is, it does not let moisture through. When immersed in a PPS fragment, it absorbs no more than 0.4% moisture, in contrast to PBS, which can absorb up to 4% of water. Therefore, the material is resistant to wet environments.

The strength of this material, equal to 0.4 - 1 kg / cm2 is due to the strength of the bonds between the individual granules of the polymer.

This material is also chemically resistant to the effects of cement, mineral fertilizers, soap, soda, and other compounds, but may be damaged by solvents such as white spirit or turpentine.

But to the sunlight and burning this polymer is extremely unstable. Under the action of ultraviolet radiation, polystyrene foam loses its elasticity and mechanical strength and eventually collapses completely, and under the action of a flame it quickly burns to produce acrid smoke.

With regard to sound absorption, this heater is able to dampen the impact noise only when it is laid in a thick layer, and it is not able to suppress the wave noise.

The indicator of ecological purity of PPP, as well as its biological sustainability is very insignificant. The material does not affect the state of the environment only if there is any protective coating on it, and during combustion it emits many harmful volatile compounds like methanol, benzene or toluene. It does not breed fungus and mold, but insects and rodents can settle. Mice and rats may well create their homes in the thickness of the expanded polystyrene plates and gnaw through the passages, especially if the floorboard is covered with them.

In general, this polymer is very durable and reliable during operation. The presence of high-quality cladding to protect against various adverse factors and the correct, technically competent installation of this material is the key to its long service life, which can exceed 30 years.

Pros and cons of using PPP

Styrofoam, like any other material, has a number of both positive and negative features that should be taken into account when choosing it for further use.All of them are directly dependent on the structure of a particular grade of this material, obtained in the process of its production. As mentioned above, the main positive quality of this heat insulator is its low level of thermal conductivity, which allows for the insulation of any construction object with sufficient reliability and high efficiency.

In addition to the resistance of the material to high positive and low negative temperatures, a significant advantage of this material is also its very small weight. It can easily withstand temperatures up to about 80 degrees and resist even in severe frosts.

Softening and violation of the structure of the material begins only in the case of prolonged exposure to high temperatures above 90 degrees Celsius.

Light plates of such a heat insulator are easily transported and installed.without creating after installation a significant load on the elements of the building structures of the object. Not letting and not absorbing water, this moisture-proof insulation not only keeps its microclimate inside the building, but also serves to protect its walls from the adverse effects of atmospheric moisture.

Expanded polystyrene has also received high praise from consumers due to its low cost, which is significantly lower than the price of most other heat insulators on the modern Russian building materials market.

Thanks to the use of PPS, the indicator of energy efficiency of the house insulated by them significantly increases, reducing the cost of heating and air conditioning of the building several times after the installation of this insulation.

With regard to the shortcomings of polystyrene insulator, the main ones are its flammability and environmental insecurity. The material begins to burn actively at temperatures of 210 degrees Celsius, although some of its brands are able to withstand heating up to 440 degrees. When PPS is burned, highly hazardous substances enter the environment that can harm both this environment and the residents of the house insulated with this material.

Styrofoam is unstable to ultraviolet radiation and chemical solvents, under the action of which it is very quickly damaged, losing its basic technical characteristics. The softness of the material and its ability to store heat attracts the pests that house their homes in it.Protection against insects and rodents requires the use of special formulations, the costs of which significantly increase the cost of installing the insulator and the cost of its operation.

Due to the relatively low density of this heater, steam condensing in its structure can penetrate into it. At temperatures up to zero degrees and below this condensate freezes, damaging the structure of the insulator and causing a decrease in the insulating effect for the whole house.

Being a material that is generally capable of providing a fairly high-quality degree of thermal protection of a structure, expanded polystyrene itself needs constant protection from various adverse factors.

If the care of such protection is not shown in advance, the insulation, which quickly lost its positive operational qualities, will cause many problems for the owners.

For information on how to insulate the floor using extruded polystyrene foam, see the following video.