Polyurethane foam: what is it and where is it applied?

One of the most controversial building materials on the market today is polyurethane foam. In common people it is sometimes called "foam rubber". PPU is widely used as a heater. However, polyurethane foam causes a lot of ambiguous reviews: some consider it universal, almost without flaws, others ruthlessly criticize.

In order to form an opinion about this material, it is necessary to systematize and summarize all the information that is available about it.

Material Features

The material is a type of plastic, to be more precise, it is a porous gas filled polymer. It is based on polyurethane components polyol and diisocyanate.

The polyol component gives the polymer base, which causes the density, hardness, flammability and other characteristics of polyurethane foam. The isocyanate component is responsible for churning.

Various additives are designed to adjust various properties. For example, flame retardants accelerate the polymerization, reduce the degree of flammability of the material.

The components individually are toxic substances, so opponents of polyurethane foam primarily pay attention to this fact. However, when mixed, toxic ingredients form an absolutely harmless mixture that is neutral and does not enter into any chemical reactions with any elements.

The process of obtaining polyurethane foam is associated with simultaneous gas formation. Since carbon dioxide is predominantly emitted, which is characterized by low thermal conductivity, PUF is endowed with excellent thermal insulation properties. That is why the material is an excellent insulation.

The rate of the chemical reaction and the mixing ratio of the components determine the subsequent characteristics of the resulting polyurethane foam:

- Flexible springy material has elasticity, but is characterized by low resistance to tearing. All known foam from this category.

- Dense and durable, it is hard but brittle when bent.

- Foamed PPU has a large range of advantages.

As a rule, PUF is obtained from petroleum products, but there is a possibility of its production from components of plant origin. For these purposes, castor, soybean, rapeseed and sunflower oils are remarkably suitable. Since the production of polyols from plant materials is less profitable, this method of production is impractical and is used extremely rarely.

Description

Polyurethane foam is of two types: foam and solid. This explains the various characteristics inherent in them. The first option is convenient when applied and ergonomic, because it leaves no seams after application. The second is intended to create shock-absorbing surfaces, to serve as a heat insulator.

Thermal conductivity

The heat-conducting properties of polyurethane foam directly depend on its cellular structure. For example, for rigid types of PU foam, the thermal conductivity varies between 0.019 and 0.035 W / (m · K).

For comparison, we can give an example of the indicator for gas glass 0.84 W / (m · K) or mineral wool 0.045-0.056 W / (m · K).

Sound absorption

The ability of materials to absorb noise of varying intensity depends on factors such as porosity, thickness, and damping properties.

From the practice of using polyurethane foam concluded that its ability to reduce the noise level depends on the rigidity of the frame and the frequency of sound vibrations. For noise absorption, it is best to use a semi-flexible type of PPU.

Chemical resistance

Polyurethane foam is considered to be one of the types of materials that is relatively resistant to aggressive chemicals. The degree of resistance he has more than that of polystyrene foam.

It has been experimentally confirmed that PPU is not afraid of gasoline, alcohol, dilute acids and various types of plasticizers. It cannot be destroyed by caustic vapors, provided that their concentration is within acceptable limits. Concentrated acid can damage the surface of polyurethane foam, but, as practice shows, not always.

Due to this property, PPU is actively used to protect metal surfaces from rust. Efficiency will depend on the brand of polyurethane foam.

Moisture absorption

The moisture absorption rate directly depends on the porosity of the material, therefore it is determined by the density of the insulation. The denser it is, the less water it absorbs.

Polyurethane foam has a low absorbent effect - 1-3% per day of the original volume.

To improve the water resistance, manufacturers introduce into the composition of PP special substances - water repellents. For example, castor oil is able to lower this threshold 4 times.

Fire and flammability

One of the advantages of PPU is its fire resistance. The material belongs to the class of self-extinguishing, readily combustible and difficult to ignite.

If it is necessary to increase the degree of durability, manufacturers introduce special additives in the form of phosphorus or halogen compounds.

It is unusually convenient and economically justified to use a coating of two layers of polyurethane foam in industrial premises with a high level of fire safety. Fire resistant is applied over the normal layer.It will be enough to keep the flame.

Density

Such a characteristic as density is important for insulation, since many different factors and functional properties depend on it.

Polyurethane foam has a density in the range of 30-80 kg / m³.

The indicator itself depends on several criteria, but there are two most important:

- polyurethane foam production technology;

- specific functional task to be performed by the PUU.

At warming different types of polyurethane foam are used: rigid, elastic, softer. Knowing the features of each type, you can save during construction without losing functionality.

Rigidity

Stiffness is not identical to density. For furniture foam rubber is characterized by the division into several grades depending on the rigidity.

- ST - the lowest degree of rigidity. It is used for upholstery of furniture armrests or backs.

- EL - modified material. Polyurethane foam of this brand is used for the production of rigid mattresses, sofa seats and other products, which implies dynamic loads.

- HR - the brand is characterized by a high degree of elasticity with initially low stiffness.The material is most suitable for the manufacture of orthopedic products and high-quality furniture.

Durability

Laboratory and industrial tests have confirmed that the life of polyurethane foam is at least 25 years. And after this time the material slightly loses its performance, allowing you to use it further.

Environmental safety

When applying liquid polyurethane foam, it must be remembered that the vapors released during a chemical reaction are contraindicated for humans. Therefore, it is necessary to protect the respiratory system with a respirator. After hardening, the foam becomes safe.

During ignition, polyurethane foam does not burn, but at high temperatures it is able to emit carbon monoxide, which is dangerous to health.

What is different from foam?

Foam rubber is a type of flexible polyurethane foam.

The cellular porous structure provides good air, vapor and moisture permeability. The degree of elasticity is regulated by adding a different type of polyol during production.

When choosing consumer goods, it must be remembered that “foam rubber” is the trade name of PPUwhich was registered in the Soviet period by a Scandinavian company of the same name.

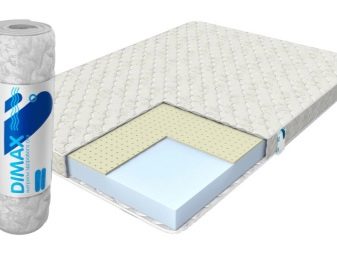

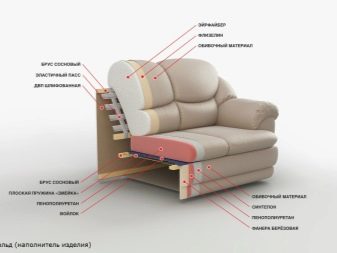

Foam rubber is mainly used in the light and furniture industry. Upholstery, fillers for mattresses and pillows, soft toys, mannequins - is a list of the most frequent use of this type of foam.

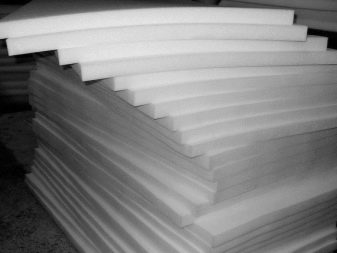

The material is characterized by different thickness and, accordingly, different rigidity. Mostly produced in the form of sheets or blocks.

Different types of foam rubber in the furniture industry are combined, which improves the quality of products.

For example, for a sofa seat using a more rigid sheet than for the back.

Orthopedic products, as a rule, should not be soft. They are designed to ensure that the body is located correctly and comfortably. For this purpose, a new kind of foam with a “memory effect” was developed. It is able to return its original shape after deformation. During operation, such material follows the contours of the body of a person lying on it, which allows you to relax as comfortably as possible.

The main mechanical characteristics of foam rubber, on which the operational life of furniture products depends:

- rigidity;

- density;

- strength;

- elasticity;

- cell size;

- support ratio.

For example, the support ratio and the cell size are decisive in highly elastic types of polyurethane foam.

Furniture foam rubber is subjected to significant loads, so bona fide manufacturers use the material with the highest density. It easily withstands long-term dynamic loads and weighting in statics.

Kinds

Experts identify three types of polyurethane foam:

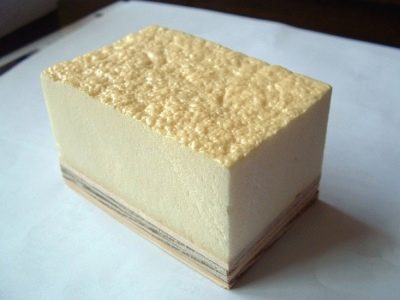

Hard

This type of material has a high density, hardness and lightness. Due to these characteristics, it is used as acoustic or heat insulation. Hard PU foam looks like slabs. One application is sandwich panels.

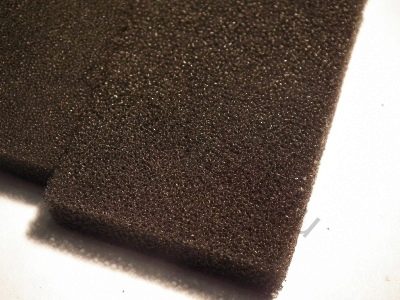

Reticulated

Polyurethane foam having an open-cell structure. It provides ventilation and hygroscopicity. Therefore, panels of reticulated foam are most often used for thermal insulation of facades and roofs. The main advantage of the material is low resistance and high dust holding capacity. This gives it the ability to filter and regenerate.In connection with this, cleaning of various liquids and gases is very popular, since reticulated polyurethane foam filters the air with a large concentration of coarse dust. One of the areas of application is the climate control system.

Elastic

The specified version of the foam like foam rubber. It is designed to create shock-absorbing surfaces, therefore it is used in the furniture industry. In connection with the ecological and chemical harmlessness it is used in the field of medicine.

The latest developments have allowed us to obtain various subspecies of elastic PUF:

- Artificial latex its properties close to natural sponge. It is characterized by elasticity, the ability to regain form, increased wear resistance, ventilation. Highly elastic characteristics were appreciated by manufacturers of orthopedic products.

- PPU with memory effect. The material has a high degree of elasticity, so that after deformation it quickly restores its original shape.

Integral

The species is characterized by solidity and dense consistency. Most often it is used in the manufacture of cars.

Foamed

The components of the foam are in cylinders in a liquid state. They are mixed during operation when applying foam to the surface.

This type of polyurethane foam is divided into two subspecies:

- PPU with closed cellular structure. When working with large-scale professionals use two-component compositions. Parts are mixed during installation, which causes a chemical reaction with the release of carbon dioxide. It gives the foam a rigid structure, the pores of which are air bubbles isolated from each other.

- PPU with open cells. For work in limited areas, as well as in everyday life, it is recommended to use one-component compositions. Most often they are called "mounting foam". In this case, all components of the composition are already mixed and are under pressure inside the cylinder. For the reaction to take place, contact with oxygen and water is necessary, which is ensured when the valve is opened and the mixture exits to the outside. Air and water vapor, as well as a moist surface, allow us to obtain a porous structure of polyurethane foam, whose cells will be open.

The second option can not compete with the first, because it loses in strength.For foaming in assembly foams, freon is used, which eventually evaporates and is replaced by air, which lowers the coefficient of thermal conductivity. Therefore, for insulation of buildings with polyurethane foam with an open cellular structure is not suitable, but for sound insulation and noise absorption is quite suitable.

Spheres of application

Polyurethane foam due to the variety of forms, types, characteristics, has a wide scope.

Building

One of the primary applications is construction.

The low thermal conductivity of the material increases its competitiveness among other heaters.

Low vapor permeability and waterproofing properties of rigid blocks of polyurethane foam allow you to use them in almost any construction work:

- thermal insulation of the exterior walls of the house, balcony, attic, roof;

- acoustic insulation from inside and outside buildings and structures (hangars, workshops, warehouses);

- hydroprotection and warming of the bases.

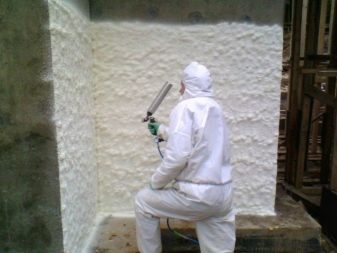

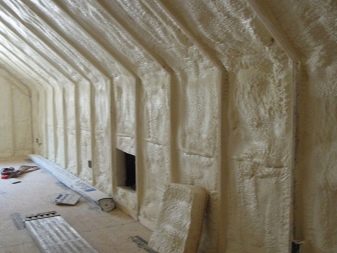

Self-expanding PU foam versions with a high degree of adhesion to the surface make it possible to use the material on any surfaces, in any conditions.

Construction and assembly works are carried out faster and better. Now it is possible to eliminate minor defects of the walls, cracks between the frames when installing windows and doors.

The main pipelines are also insulated with polyurethane foam. For insulation, as a rule, use three methods:

- Fill A polyurethane foam mixture is poured between the main pipe and the polyethylene casing, which allows to optimize production, as the number of operations decreases, the structural strength increases, and a high degree of temperature resistance is achieved. This method of insulation significantly reduces heat loss. The main oil and gas pipelines are more often isolated in this way.

- Spraying The method is used for large diameter pipes. As in the first case, the method provides a seamless application of insulation. It may be noted as an advantage that the deposition can be made on site. The temperature range of the insulating layer is from minus 80 to plus 130 degrees.

- PPU shells. For isolation of external pipes they create shells of polyurethane foam about a meter long and up to 10 cm thick.

In the composition of modern sandwich panels used for industrial and civil construction there is also PU foam. This building material is a multilayer structure consisting of two coating layers and insulation.

When using polyurethane foam as a heat insulating layer with a thickness of 3.5 cm, an effect similar to the use of a panel with mineral wool 12.5 cm thick is achieved. You can even compare such a panel with a brick wall 96 cm thick. The main advantages of sandwich panels are lightness, durability, durability, high degree of thermal insulation, low moisture absorption coefficient, high construction speed, and lack of construction waste.

Architectural decorative elements in recent times are also made of polyurethane foam. These include bas-reliefs and statues, stucco and baguettes, cornices, columns, balustrades and much more.

Automotive industry

Integral polyurethane foam is used in the manufacture of car seats as fillers, as well as insulation of the cabin itself.

All soft panels inside the car are also made using PPU: armrests, handles, head restraints, steering wheel and even bumpers.

Reticulated foam rubber is used to create a climate control system.

Furniture industry

Furniture manufacturers use PPU as a filler or cushioning material. Molding of pillows, mattresses, various rollers does not do without its participation. Since the density varies, it is possible to achieve different degrees of elasticity and provide any relief.

With the improvement of some properties, you can get a new type of foam. So, for example, a viscoelastic material with a memory effect was obtained. It is used for orthopedic pillows and mattresses that adapt to the structure of the body of a person sleeping on them, which improves the quality of sleep and rest.

The elastic version of polyurethane foam keeps its shape well and maintains a considerable weight, so furniture based on it will last for a long time. In addition, it does not accumulate dust and it is breathable, which is especially important for allergy sufferers. Manufacturers warn that if furniture jumps, as children often do, then elasticity will decrease much faster.

Light industry

The production of shoes and various items of clothing often uses soft plastics in the form of polyurethane foam. For example, instep supports for heels, various reliefs. Polyurethane foam outsole is long and has no complaints.

Foam rubber is the most common filler of soft toys and mannequins.

For everyday life polyurethane foam produced various sponges for washing dishes, rollers for painting, scouring pads, “brushes”. In this case, a special purpose PPU is used, since it is necessary that it does not crumble during operation, withstand constant contact with water and household chemicals. Manufacturers for these purposes add special fillers that improve the quality characteristics.

Reticulated polyurethane foam is a material for the production of air filters in any air purification systems: household and industrial air conditioners, vacuum cleaners. Filtration of water in an aquarium, oil products and various types of oils, fuel and lubricants in the production and transportation - this is a considerable list of its applications.

Careful transportation of fragile goods is not complete without packaging made of polyurethane foam.

Chemical industry

Isolation of low-temperature pipelines does not do without PPU.

Polyurethane foam is widely used as a cold insulator in any technique.

The medicine

Viscoelastic foam rubber brands are used in the field of medicine for the manufacture of various linings for burns and other skin lesions, which makes it less disturbing to the injured areas.

Also widely used material for the manufacture of contour orthopedic pads and holders: rollers, backs or cylinders.

Manufacturers Overview

Polyurethane foam insulation is becoming popular in recent times. Therefore, new manufacturers of these products appear on the market, as well as contracting firms that provide services for its installation.

Respectable PPU suppliers produce components under their trademarks. The rest, as a rule, are resellers, buying components from well-known brands. Some firms use the services of local refineries.

Using consumer reviews, there are several reliable manufacturers of polyurethane foam:

- Basf - German chemical concern, which has its branches in 160 countries of the world.The brand produces a wide range of products. More than 7,000 items, 60% of which are sold on the European market, about 22% of sales are in the United States of America, the rest is distributed among the markets of South America, Asia, Africa and the Pacific. In Russia, the company has several subsidiaries, including BASF Construction Systems LLC, BASF Vostok LLC, Wintershall Russland. One of the well-known joint ventures producing polyurethane foam products is the Elastokam company. The company manufactures polyurethane systems, available to consumers of any level, for various applications.

- Synthesia Internacional S.L.U. - Spanish chemical company, founded in 1964. Since 1966, the main direction is the production of polyesters, as well as polyurethane systems for various industrial sectors, for example, thermal and acoustic. Since 1970, polyurethane foam for sandwich panels, construction and refrigeration systems first appeared in the range. Today the company manufactures products for different market segments. The most famous distributor of products in Russia is Global Therm LLC.This company provides direct deliveries, carries out a certain stock of products in a warehouse in Moscow, and guarantees a flexible system of payment and advice from technical specialists.

- Sipur (Poland) - one of the largest manufacturers of sprayed polyurethane foam insulation. Thermal insulation products are characterized by low thermal conductivity, which allows the insulation to be applied in a thinner layer (deposited thickness up to 6 cm). The company guarantees the service life of PPU about 50 years. Thanks to the closed cellular structure, the heat insulation not only retains heat, but also makes it possible to strengthen the structures and protect them from moisture. Insulation density is 18-22 kg / m3, the degree of air permeability is about 0.0045 kg / (m2 * hour), the temperature range for operation is from -70 to +100 degrees. Modern innovative material is patented, developed specifically for the CIS market, therefore, combined reasonable prices and high quality characteristics.

- Icynene (Canada). The brand produces energy-efficient polyurethane foam insulation for private and industrial construction. More than 300 countries have confirmed with certificates the quality of the material produced.Guaranteed period - 25 years. The company entered the market of polymer insulation since 1986.

- Wanhua (China). The company began production in 1998 and has now achieved worldwide recognition. The company has several quality types of PU foam, aromatic polyamines, polyisocyanate (MDI). The latter is produced at two plants with a total capacity of up to 500 thousand tons per year.

Advantages and disadvantages

The heat-insulating construction area has been developing at a fast pace lately. Innovative technologies and the latest equipment have made it possible to reach certain heights in the field of insulation finishing materials. Traditional insulation cannot provide such a long operational period without loss of protective properties, while new heaters create comfort, make it possible to save on heating, eliminate drafts, increase noise and moisture insulation. To correctly use the material, you need to know and take into account all its pros and cons.

The advantages and disadvantages of different types of PUF differ significantly.

Foam rubber

The well-known foam rubber, which has been widely used since the sixties of the 20th century, is valued for softness, springiness, the ability to change shape, it can be cut, glue, and sew.The material was used in the furniture industry, in the production of children's toys, as packaging, in everyday life, and so on.

The most significant are the following advantages:

- High wear resistance.

- Hypoallergenic. The material is safe for the production of goods for children.

- Not susceptible to the formation of harmful microorganisms.

- Elasticity.

- A variety of models. Depending on the stiffness, color, thickness, PUF can be used in different areas.

- The term of operation is from 5 to 15 years depending on the density and functions performed.

However, with all the advantages of foam rubber, there are also significant disadvantages:

- It contains a toxic compound toluene diisocyanate.

- Foam rubber is hygroscopic. Absorbs odors and keeps them for a long time.

- It has a limited temperature range.

- The low term of operation in comparison with rigid types of PPU.

- Flammable. The material is highly flammable, therefore according to GOST it belongs to the group of flammable, highly flammable and toxic when burning substances with a high degree of smoke formation.

Manufacturers tried to introduce flame retardants into the composition of foam rubber,which would increase its fire resistance.

However, this led to a deterioration of the physicomechanical properties, and also caused a significant increase in cost.

Self-foaming formulations

We list the most famous advantages of polyurethane foam, which make it popular:

- The cellular structure of the PUF provides an effective degree of thermal conductivity.

- The possibility of spraying avoids seams and joints, increases the effectiveness of insulation.

- A variety of types of polyurethane foam facilitates work with surfaces of any shape.

- The low degree of hygroscopicity allows not only to provide thermal insulation, but also to waterproof structures.

- High vapor permeability.

- After spraying polyurethane foam has a neutral smell.

- High adhesion coefficient. This property can sometimes be considered as a disadvantage, since the PUF sprayed onto the surface can be removed only by mechanical means. There are no special solvents for this purpose.

- Low weight. The material does not weigh down the surface.

- PPU allows you to strengthen the walls when applied.

- Large temperature range.

- Durability. Warranty period is usually around 20-25 years.However, manufacturers claim that even after twenty years, the quality characteristics deteriorate slightly.

- Low time interval for surface treatment with polyurethane foam.

- Fireproof. The material does not burn, it is self-extinguishing.

Among the disadvantages are the following factors:

- High price. The difference, for example, with mineral wool, is 2-3 times. However, it should be noted that the service life is much higher.

- If PPU is applied by spraying, the quality depends on the skill of the specialist.

- High-tech equipment for spraying polyurethane foam is expensive, so not everyone can afford it, but only specialized firms.

- When ignited, PPU smolders and emits acrid smoke. Harm to health brings it.

- The material is afraid of ultraviolet radiation, so under the action of sunlight it darkens, takes on an unattractive look. To protect the PU foam is better to apply the finishing. In addition, the sun causes the upper layer to melt, but if there is sufficient thickness, it will protect the lower layer from destruction.

How to insulate yourself?

It is possible to divide the process of wall insulation into two types: internal and external.

Internal

From the name it follows that the work is done indoors.Most often they warm corners, loggias or balconies.

Polyurethane foam allows you to handle even such problem areas as the bathroom and kitchen.

The material has good moisture-proof properties. To exclude hygroscopicity, vapor barrier with foil layer, which should be located inside the room, must be laid on top of the PPU.

When weathe loggias or attic, polyurethane foam will help to avoid heat losses and save heating costs.

Technology of warming balconies and loggias

In order to insulate a small balcony or loggia, it does not take much time. Usually for these purposes a standard set of tools and materials is required:

- aluminum profile for lathing (from any building supermarket);

- self-tapping screws with dowels;

- drill;

- PUF components (it is better to purchase a ready-made kit);

- gun distributor - if you buy a ready-made set, then the equipment is already in it;

- personal protective equipment - gloves, goggles, respirator;

- building level.

At the preparatory stage, the walls and the ceiling are cleaned from the old coating, peeling plaster and other debris.If there are deep gaps in the joints between the walls or in the corners, it is better to fill them with pieces of foam and putty. Minor defects are not required to be eliminated, since foam will cope with this task.

The second stage is to install the batten. To do this, the profiles are fixed along the walls at regular intervals, fastening them with perpendicular bridges. Experts advise cracking all openings, window and door, around the perimeter. Next, you should cover all windows, door panels and communications with polyethylene, so as not to spoil during the application of insulation.

The third stage is spraying. According to the instructions to the components of the insulation, the pistol is collected, the feeding hoses, nozzles. The cylinders are thoroughly shaken before use. First of all, it is necessary to fill the gaps in the joints between the ceiling and the walls, the corners and process the openings. For these purposes, serves a narrow nozzle. Further, it is better to use a wider spray to uniformly apply polyurethane foam on the surface of the ceiling and walls. In places with minor defects or irregularities, the insulation is applied with a thicker layer to even out.After the end of work, the excess polyurethane foam must be removed from the batten.

The final stage - finishing. Plasterboard is attached to the crate if in the future it is planned to paint the walls, cover them with plaster or apply wallpaper. Finishing using plastic or wooden panels is often practiced.

It must be remembered that in the case of plastering it is necessary to reinforce the reinforcing glass fiber mesh before applying the finishing layer.

Basement

Damp basements are particularly in need of insulation and waterproofing. Stages of work:

- The procedure for isolating the surface from excess moisture. For a start, the floor is covered with roofing felt. It should be remembered that the sheets stacked overlap, on the walls of the plant at 20 centimeters. In order to ensure high-quality tightness, ruberoid on the perimeter is coated with mastic, it is also better to proceed with joints. In the case of low humidity in the basement, the walls are also treated with mastic to a height of 10-15 cm from the floor. Deformation of the protective coating will help avoid screed.

- The application of polyurethane foam insulation starts from the corner to the exit. It is better to make 3-4 layers, clearly tracking the level over the entire floor area.

- A concrete screed is applied evenly over the foam. Rule level thickness. The minimum allowable thickness is 5 cm.

- Finishing. After drying the screed for at least two or three days, the floor is covered with tiles, panels, linoleum or any other material.

Attic and attic rooms

Work with polyurethane foam insulation in the attic depends on the method of subsequent finishing.

- If the attic after insulation is planned to sheathe eurolining or drywall, the foam should be applied between the rafters. At the same time, it is not necessary to cover floor beams with waterproofing, antiseptic or a primer.

- If finishing finishing means decorative plaster, then it is necessary to put PPU on all surfaces, including on beams.

To begin work it is necessary from joints and seams between walls and a roof. It is important to monitor the uniformity of the insulation layer. Conveniently, the finishing can be started in a small amount of time, since the insulation freezes almost instantly.

Outdoor

External insulation of the facade of the building allows not only to retain heat, but also to avoid dampness, mold and other harmful microorganisms.

For outdoor work most often used self-foaming modifications of polyurethane foam. They are applied evenly, without seams, filling all the defects and irregularities of the walls. In addition, the material has excellent adhesion, suitable for insulation as a wooden house, and structures made of concrete and bricks. PPU quickly hardens.

In connection with the fear of sunlight, it is necessary to cover it with a finishing decorative protective layer.

There are two ways to insulate the roof or walls with polyurethane foam, depending on the type of insulation used:

- With use of PPU of elastic structure. The ductile material has a porous structure and is distinguished by its low density. In this regard, such insulation allows roof insulation with simultaneous noise insulation.

- Using hard PU foam. The material is most common in construction because it has a high density.

This results in the following performance characteristics:

- moisture resistance - protection of the roof from the action of water;

- resistance to deformation, so that the insulation can withstand significant loads;

- low weight of PU foam reduces the overall load on the foundation;

- ease of installation - thermal insulation does not require parsing structures, additional training.

In the construction of private houses, the first method is more often used, while the insulation of dimensional structures is the second.

The main stages of applying polyurethane for warming a low-rise building with their own hands:

- Base cleaning and the elimination of major defects on it. At this stage it is necessary to clean the walls, the necessary parts of the floor or ceiling from dust, old coating and various dirt. The procedure will improve the adhesion of the foam to the surface. At the same time, experts note that it is not necessary to level the bases.

- Drawing a polyurethane foam layer using special equipment. Spray produced on peeled grounds. The thickness of the polyurethane foam layer will depend on several factors. On the aligned surface of the material will take less. Also affects the type of warmed floors themselves. A preliminary calculation of heat loss will help to avoid unnecessary costs, providing the necessary protection.

- Reinforcement special tie. As a reinforcement, a fiberglass mesh with small holes is usually used.Professionals advise not to lay the reinforcing layer less than 6 cm.

- Finish For the protection of polyurethane foam insulation, you can use any materials: brick, plaster, artificial or natural stone, paint for facades, siding and others.

Large firms working on the construction of large-sized buildings and structures, often use a hard type of polyurethane foam. This reduces time and cost.

In addition, the insulation of the hangar, warehouse or high-rise building is economically advantageous to cover it with such polyurethane foam, because it is more durable, faster applied, does not require additional costs for the alignment of the walls.

Apply foam can be two methods:

- Spraying The process takes place with the help of special equipment in the form of a pistol, into which two components and water are supplied. A chemical reaction occurs, the result is a PUF, an even layer lying on the open surface.

- Fill In this case, the components are mixed in advance and the resulting mixture is poured into the hole. The method is suitable for closed and hard-to-reach places, complex architectural forms (niches, arches, various projections, corners, columns), old buildings.

Useful tips from the pros

- With independent insulation of facades of buildings, it is necessary to take into account that after applying polyurethane foam to the surface, it increases in volume within a short period of time. Therefore, it is better to foresee the amount of the applied material in order not to break the cracks filled by it during the expansion.

- PU foam hardens very quickly and possesses super-adhesion with any types of surfaces. There is no means that would allow it to be washed off. In this regard, it should be borne in mind that the time to perform the work itself and eliminate inaccuracies is extremely small.

- For filling cavities, for example, between a facing brick wall and a foam block, it is better to use special mixes for casting. They do not expand as quickly as foam, so the construction will not burst. However, it should be noted that the cost of such a system is much higher.

- Often, water is used for foaming polyurethane foam, so experts do not advise applying such a heater on galvanized surfaces. This will worsen the properties of the metal. Also for galvanization closed-cell modifications of PUF are not suitable.Since the metal has sufficient strength, it does not need additional strengthening.

- It is obligatory to cover the top with some finishing material for external treatment, since polyurethane foam is afraid of ultraviolet radiation.

- Before the start of insulation, it is better to make a preliminary calculation to determine the amount of foam. First, the thickness of the applied layer is calculated. For example, for a roof area of 45 square meters. m. the best option would be the size from 6 to 10 cm. If you increase the area to 50 square meters. m and more, the range will drop to a level of 3-7 cm. When calculating the heat-saving effect, the number of window and door openings, the material of the walls, the presence of energy-saving materials, the climate of the region are also taken into account.

- Before insulating the wall from the inside, it is necessary to evaluate its coefficient of thermal resistance. If the surface is warm, then polyurethane foam insulation is best applied outside. In this case, the heat resistance of the wall and the foam are added, and therefore, the desired effect is achieved. If you do the opposite, then the external surface will freeze, which will adversely affect the overall thermal resistance.

- For self-use it is better to purchase disposable kits for applying foam. They provide everything: spray, hoses, attachment devices, tools, spare parts, even personal protective equipment (goggles, gloves and respirator).

- You should not worry that wooden racks, for example, roofing beams, under the vapor-tight polyurethane foam shell will deteriorate. The coefficients of vapor permeability in wood and PUF are approximately the same, which eliminates the occurrence of such problems.

- It is not recommended to process the roof from the inside with open-cell PU foam. Of course, as heat insulation it is better than other mineral insulants, but since it is worse vapor insulation, additional costs for ventilation and an insulating layer will be required. Therefore, this option is considered not economically viable.

- Polyurethane is not able to cope with fire, although it is fireproof. Therefore, if there is a constant effect of high temperatures on the warmed surfaces, then it is better to refuse PPU. When burning, it smolders and emits acrid smoke that is unhealthy.

Contractor selection

Insulation of buildings and structures requires special practice, sophisticated equipment and high-quality components of the mixture. Therefore, if there are financial opportunities, it is better to use the services of specialized firms. In order not to be trapped, professionals advise to adhere to the following rules when choosing them:

- Hire better proven companies with recommendations.

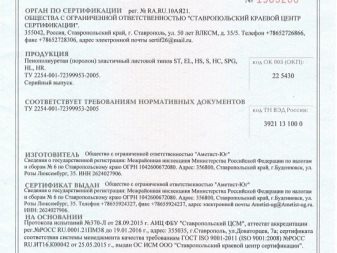

- The components of polyurethane foam insulation must have quality certificates.

- Before starting work it is better to make sure that the storage period of the components has not expired.

- Equipment for spraying and filing PPU must also have documents. As a rule, contractors who have long been working in the field of construction with large objects use high-pressure apparatuses of well-known world brands that have established themselves in this field. For example, Graco or Gama.

Plunger pumps provide uniform application of polyurethane foam.

Before you sign a contract, you need to carefully read all of its terms and clarify all the incomprehensible places related to the terms of completion of work, payment, prepayment, etc.

On the features of sprayed polyurethane foam and how to apply it, see the following video.