Features sprayed insulation Polynor

Among the modern foam polyurethane insulation materials, one of the leaders is Polynor sprayed insulation, developed by Norwegian experts. It is several positions superior to heat insulators from other manufacturers.

High technical characteristics of this sprayed heater allow with good reason to consider its use as one of the most effective ways to preserve heat in the house.

Properties and scope

It should be noted that in general, insulation based on polyurethane foam somewhat lose their classic counterparts in terms of affordability. For this reason, these insulation materials have not yet received as widespread as insulating building materials made of mineral wool, polystyrene foam and polystyrene, the production of which is based on the extrusion method.

The issue of availability for the purchase of polyurethane insulation materials due to the fact that the insulation of the house requires a fairly large consumption of foam insulation. Until recently, such a problem was solved by attracting various contractors or in the case of an attempt to solve it on their own by acquiring raw materials and special equipment, as well as the need for personal development of thermal insulation technology.

The emergence of Polynor insulation on the market has radically changed the situation. Now, to insulate any, even a very large surface, the consumer does not need to resort to the services of third-party executors and expend funds to purchase expensive equipment.

Liquid foam insulation Polynor is produced by the manufacturer in compact cylinders. The consumption of the contents of one such cylinder, provided that a heat insulating layer with a thickness of 6 cm is created, is equal to 1 m² of the treated surface. At the same time, a comparison of the cost of Polynor thermal insulation sprayed from a cylinder with the cost of paying for the services of a third-party organization for home insulation is clearly in favor of the option of spraying liquid insulation.

It is known that the average estimate of the cost of work on the insulation of 1 m² with a polyurethane foam insulator by a team of specialists is approximately 1 thousand rubles, taking into account the cost of the material and the work performed. While one cylinder of Polynor insulation for the same square meter of heat insulated surface of the gable or attic will cost the consumer approximately 500 rubles.

This type of heat insulator is recommended for insulation of premises from the inside or outside by applying it on the internal surfaces of walls and facades of houses from any material - brick, concrete or made of gas silicate blocks. This also includes lag floors and any cover with a structure that does not carry the dynamic load. This heat insulator can be used to insulate the internal surfaces of pitched roofs, attics, attic floors, basement foundations, basements and basements of buildings.

Thanks to the Polynor liquid form, it can be applied to absolutely any surface. Therefore, this material has been successfully used for insulation of sewage pipes and highways of both hot and cold water supply, which are taken out of the construction sites.

It should be noted that the operational capabilities of this heater are somewhat limited by the balloon form of its release., which does not allow to create a level of pressure that allows zapenirovat voids inside hollow walls, that is, this material is suitable only for external spraying. Regarding the issue of labor productivity when working with this material, according to those consumers who have already used it, one person can process Polynor about 80–100 m² of heat-insulated surface within one working day.

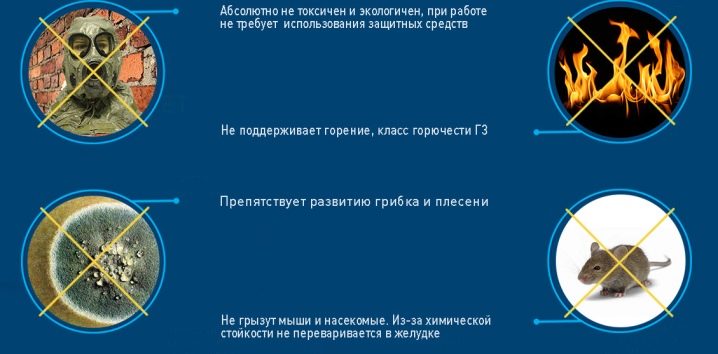

In addition to convenience and simplicity in the process of work and high efficiency of the spraying thermal insulation of the Polynor brand, its key advantages over analogues from other manufacturers, such as the ability for rapid solidification, no more than one hour, and the absence of the negative impact of this material on human health can also be singled out.

Thermal insulation Polynor does not attract rodents as a food source. It does not create bridges for cold and with the highest efficiency in use does not need special expensive equipment for its installation. The closed cells of this durable material do not allow moisture and steam to pass through, and it is capable of self-extinguishing in the absence of direct contact with fire.

Advantages and disadvantages

This type of heat-insulating material in comparison with analogues from other manufacturers is distinguished by ease of installation, which does not require the creation of a skeleton and the use of such materials as films, izospan, adhesive composites, fasteners, reinforcing mesh and the like. This heat insulator is conveniently used when working in hard-to-reach and spatially confined places and where there is a complex profile of the surface to be coated.

Polynor application technology does not require the use of special equipment and energy consumption. This material, which has one of the best thermal conductivities on the background of similar heat insulators, also has excellent adhesion to a wide variety of building materials, starting with brick, concrete or wood and ending with metal and glass.

At a very high coating speed, when an area of 1 m² is covered with this material for one, maximum two minutes, Polynor is characterized by a low degree of consumption. One cylinder having a volume of 1000 ml is enough to apply a six-centimeter layer per square meter of surface.

The polymerization process of this heat insulator takes one hour,After that, the coated surface of Polynor can be painted, plastered and applied to it with any other coating or protection. This environmental safe material does not emit harmful volatile compounds in the process of operation, it has a long working life, which, according to the manufacturer, is about 35-50 years.

In addition to thermal insulation itself, Polynor is a sound-insulating material, it is not loved by rodents and insects, it is resistant to the effects of fungal mold and other biological factors.

As for the minuses of this material, it is not resistant to direct solar ultraviolet radiation like a mounting foam and is short-lived with regular contact with water. Installation of the Polynor is possible in somewhat limited temperature conditions.

The process of its deposition is characterized by the difficulty in obtaining a layer of uniform thickness, as a result of which the finished coating may have non-uniform thermal conductivity. Therefore, a better, uniform deposition depends on experience with this material. It should take into account the manufacturer's recommendation, according to which the thickness of the applied layer is limited to 6 cm.

In the process, the cylinder can be used at temperatures in the range between +18 and + 35 ° C. This hydro insulator, as already mentioned, is toxic at work, which entails the mandatory use of personal protective equipment.

Polynor is not hygroscopic, therefore there is a sealing effect on the surface covered by it, which serves as an obstacle to vapor absorption. The supply of insulation in cylinders requires a separate purchase of a construction gun, equipped with a special nozzle. In case of loss or breakage of a pistol or nozzle, it will be necessary to purchase new ones, since without them the quality of the spraying process, according to the manufacturer, is significantly reduced.

Application technology

Before you start working with Polynor to insulate the area of any surface, you should prepare it accordingly. For this purpose, it is necessary to thoroughly remove accumulations of dirt and dust from such a surface, and in the presence of greasy and oily stains, remove them with acetone or white spirit. Degreasing the heat-insulated surface is necessary because the sprayed Polynor adheres to an oily surface much worse than a clean brick or concrete wall.

If there are any chips, holes, cracks or other damage to the heat-insulated surface, they should be sealed with a cement mortar or adhesive composite. Until the moment of starting work with it, it is necessary to hold the cylinder with a heater indoors for a while at an air temperature above + 18 ° C. This is done in order to prevent the working substance from hardening and to obtain a uniform layer after its application.

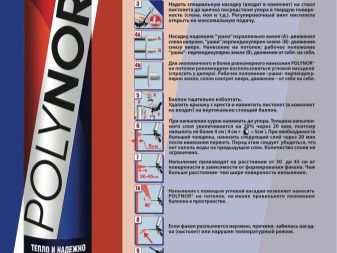

Preparation for the use of Polynor insulation is to install a special nozzle on the balloon. It is put on until it clicks, after which the lid is removed from the cross and a mounting gun, which is purchased separately, is connected. All these manipulations are performed under the condition that the product packaging is held in an upright position.

From the moment you start work and during its implementation, the balloon must be shaken periodically. The application of insulation to the surface is carried out by spraying it by pressing the lever of the mounting gun. At the same time, the obtained thermal insulation layer should have a thickness of not more than 500 mm. At the end of this work, the gun is disconnected from the cylinder and its parts are cleaned with liquid solvent.

Heat insulation spraying should be carried out in strict accordance with safety regulations, since liquid polyurethane foam before it hardens is harmful to the human body.

It can cause irritation of the eyes, mucous membranes of the respiratory organs and those skin areas to which it accidentally falls. Therefore, installation work with Polynor should be carried out in protective clothing, construction glasses and gloves. Included with each package of Polynor thermal insulation is a detailed instruction on the use of this material with the necessary explanations and recommendations.

Polynor Insulation Reviews - in the next video.