Rockwool Insulations: Variants and Their Specifications

Rockwool is a leading global manufacturer of thermal and sound insulation materials based on stone wool. The range has a large variety of insulation, differing in size, form of release, technical characteristics and, accordingly, the appointment.

A little about the company

This trademark was registered in 1936 and correctly looks like a Rockwool. The manufacturer insists on writing in Latin, without quotes, only in capital letters.

The company appeared on the basis of a company engaged in the extraction and sale of coal and rocks, registered in Denmark in 1909.The company also conducted the production of roofing tiles.

The first insulation was released in 1936-1937, at the same time the name Rockwool was registered. Literally, it translates as "stone wool", which accurately reflects the characteristics of thermal insulation materials based on stone wool - they are light and warm, like natural wool, but at the same time durable and long lasting - just like stone.

Today, Rockwool is not just one of the best manufacturers of heaters, but also a company that produces innovative products in its field. This is due to the presence in the company of its own research centers, the development of which are being introduced into production processes.

Production of insulation under this brand today is established in 18 countries and 28 plants located in them. Representative offices operate in 35 countries. In Russia, products appeared in the early 70s, initially for the needs of the shipbuilding industry. Due to the high quality, it gradually became widespread in other areas, primarily construction.

The official representation which appeared in 1995 made the brand even more popular.Today there are 4 factories in Russia where products are manufactured under the brand Rockwool. They are located in the Leningrad, Moscow, Chelyabinsk regions and the Republic of Tatarstan.

Special features

One of the distinguishing features of the material is its environmental friendliness, as evidenced by the presence of certificates of conformity of products to EcoMaterial standards. In addition, in 2013, the manufacturer became the holder of the Ecomaterial 1.3 certificate, indicating that the company's production activities are environmentally friendly. The safety class of these materials is KM0, which means their absolute harmlessness.

The concept of the manufacturer - the creation of energy-efficient buildings, that is, objects characterized by an improved microclimate and energy savings of up to 70-90%. Within the framework of this concept, material with the lowest possible thermal conductivity is distinguished, and many insulation options are being developed for specific surfaces, types of objects and areas of the same structure.

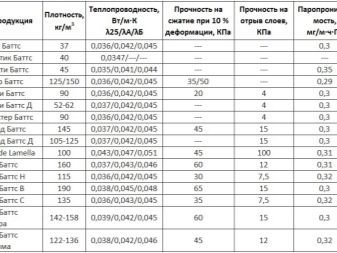

In terms of its thermal conductivity, basalt plate insulation of the brand under consideration is ahead of similar products of many European manufacturers.Its value is 0.036-0.038 W / mK.

In addition to high thermal insulation indicators, the materials of this brand are used for sound insulation.

Due to the high sound insulation coefficients, it is possible to reduce the effect of airborne noise to 43-62 dB, and the impact one - to 38 dB.

Thanks to a special hydrophobic treatment, basalt insulation Rockwool is moisture resistant. It does not absorb moisture, which significantly prolongs its service life and increases frost resistance, as well as ensures bioresistance of products.

Basalt heaters of this brand are characterized by excellent vapor permeability, which allows to maintain an optimal microclimate in the room, as well as to avoid the formation of condensate on the surface of the walls or materials used for insulation and finishing.

Rockwool insulants have a fire safety class of NG, which means they are completely non-flammable. This allows the use of plates, not only as a heat-insulating, but also fire-resistant barrier material. Some types of insulation (for example, reinforced with a foil layer) have a flammability class G1. In any case, when heated, the products do not emit toxins.

These specifications ensure the durability of thermal insulation products, the service life of which is 50 years.

Kinds

Products Rockwool has hundreds of types of insulation.

The most popular are the following types:

- "Light Butts". Insulation used to isolate non-loaded structures, due to its low density. In this, it is similar to the “Economy” modification used on unloaded horizontal, vertical and inclined surfaces. A feature of this product is the flexi technology used. It implies the ability of one of the edges of the plate to “spring up” - to shrink under the influence of the load, and after removing it - to return to the previous forms.

- "Light Butts Scandic". An innovative material that also has a springy edge and is characterized by its ability to compress (i.e. the ability to compress). It makes up to 70% and is provided with a special arrangement of fibers. This feature allows you to reduce the volume of the material when it is packed to its minimum size and get compact products that are easier and cheaper to transport compared to analogues of similar size and density of other brands.After opening the package, the material acquires the specified parameters, compression does not affect its technical characteristics.

In addition to the size and thickness of the plate, these materials do not differ from each other. The coefficient of their thermal conductivity is 0.036 (W / m × ° C), vapor permeability is 0.03 mg / (m × h × Pa), moisture absorption is not more than 1%.

Materials for ventilated facade

- Venti Butts it can be laid in one layer or protrude as a second (outer) layer with a two-layer thermal insulation coating.

- "Venti Butts Optima" - insulation, having a similar purpose as the version of Venti Butts, as well as being used as a material for the manufacture of fire breaks near door and window openings.

- "Venti Butts N" is lightweight, so its use is possible only as a first (inner) layer with two-layer thermal insulation.

- "Venti Butts D" - unique plates for ventilated facade systems, combining the features of both the outer and inner insulation layer. This is ensured by the difference in the structure of the material from its 2 sides - the part that is attached to the wall has a looser structure, while the side facing the street is more rigid and dense.A characteristic feature of all types of plates "Venti Butts" is that with their proper installation, you can refuse the use of a wind-proof membrane. This is due to the fact that the outer surface of the plates is strong enough, and therefore weatherproof. As for the density, its maximum indicators are typical for the plates “Venti Butts” and “Optima” - 90 kg / m³, the outer side of the “Venti Butts D” (inner - 45 kg / m³) has a similar value. Density “Venti Batts N” - 37 kg / m³. The coefficient of thermal conductivity for all modifications of the fan heater varies between 0.35-0.41 W / m ° C, vapor permeability is 0.03 (mg / (m × h × Pa), moisture absorption is not higher than 1%.

- "Kaviti Butts." Insulation used in three-layer, or "well" masonry facade. In other words, such a material fits into the wall space. A distinctive feature is the compacted edges of the plates, which ensure the tightness of all the elements of the facade (that is, the insulation of the insulation to the facade and the supporting wall). For concrete or reinforced concrete three-layer system, the manufacturer recommends the use of the type "Concrete Element Butts".The latter has a density of 90 kg / m³, which is 2 times the density coefficient of the "Cavity Butts". The thermal conductivity of both products under different conditions and installation systems is 0.035-0.04 W / m × ° C, vapor permeability is 0.03 mg / (m × h × Pa), moisture absorption is not more than 1.5% for Cavity Butts. and no more than 1% for its more durable counterpart.

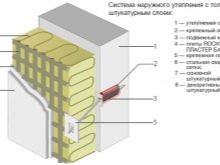

Thermal insulators "wet" facade

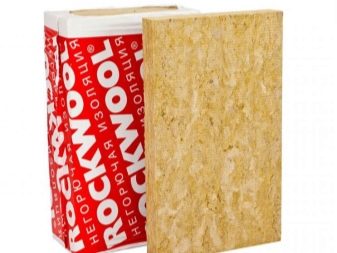

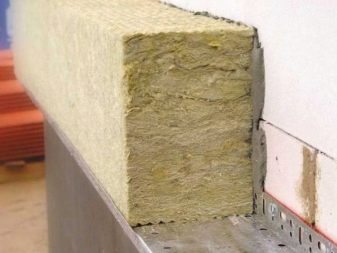

Their distinctive feature is increased rigidity, thanks to which contact finishing of heat-insulating plates becomes possible.

- "Rokfasad" - the type of plates which has recently appeared in assortment, intended for use in country construction.

- "Facade Butts" - slabs, increased rigidity, thereby withstanding heavy loads.

- "Facade Lamella" - thin insulating strips, optimal for insulating curved facades and walls with a complex configuration.

- "Plaster Butts" it is applied under a thick layer of plaster or finishing with clinker tiles. A distinctive feature is the reinforcement with steel galvanized mesh (and not fiberglass as for other types of slabs for plaster),as well as the use of movable steel brackets for fixing (and not the “fungi” dowels).

In addition to these options, under the "wet" facade used plate "Optima" and "Facade Butts D".

The density of the plates is in the range of 90-180 kg / m³. Plaster Butts and Facade Lamella products have the lowest indicators. The largest is “Facade Batts D”, the outer side of which has a density of 180 kg / m³, internal - 94 kg / m³. Intermediate "options -" Rokfasad "(110-115 kg / m³)," Facade Butts Optima "(125 kg / m³) and" Facade Butts "(130 kg / m³).

Density and vapor permeability of plates is similar to the same indicators of the types of heaters considered above, moisture absorption is not more than 1%.

Under the screed

Warming the floor under the screed requires high strength insulation material. And if the variation "Light Butts" or "Scandic Butts" is suitable for thermal insulation of the floor on the logs, then other modifications are applied to isolation under a coupler:

- "Flor Butts" used for insulation of floors and floating acoustic floor.

- "Flor Butts And." Scope of application - warming of the floor subject to the raised loadings. The purpose of the second floor is due to its higher strength indicators - 150 kg / m³ (for comparison, the proportion of Flor Butts is 125 kg / m³).

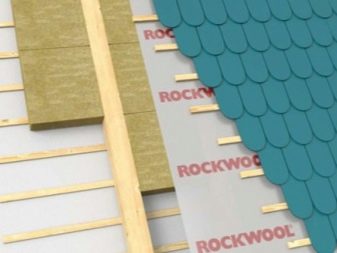

For a flat roof

If “Light Butts” and “Scandic” insulators are suitable for pitched roofs and mansards, flat roof implies a significant load on the insulation, and therefore requires the installation of a more dense material:

- "Ruf Butts In Optima" - single-layer insulation or top layer with a two-layer thermal insulation layer.

- "Ruf Butts In Extra" it has high rigidity and is suitable as an upper insulation layer.

- "Ruf Butts N Optima" - slabs of low density for the lower layer in a multi-layer insulating “cake”. Variety - "Extra". Differences - in the parameters of the plates.

- “Ruff Bat D” - combined products with different stiffness from the outer and inner sides. In this modification, the plates are produced "Extra" and "Optima".

- "Ruf Butt Coupler" - plates under a coupler on the operated roofs.

The maximum density of materials are marked “D”, the outer layer of which has a specific weight of 205 kg / m³, internal - 120 kg / m³. Then, in descending order, the specific weight ratio is “Ruf Batts V” (“Optima” - 160 kg / m³, “Extra” - 190 kg / m³), “Coupler” - 135 kg / m³, “Ruf Batts N” (“Optima "- 110 kg / m³," Extra "- 115 kg / m³).

For saunas and baths

Scope of application "Sauna Butts" - thermal insulation of baths, saunas. The material has a foil layer, thereby increasing its thermal insulation characteristics, moisture resistance and strength without increasing the thickness of the product. Due to the use of the metallized layer, the class of flammability of the material is not NG, but G1 (slightly combustible).

Scope of application

- Thermal insulation materials Rockwool are widely used in construction, in particular, for the insulation of external walls of buildings. With the help of heaters, it is possible to improve the thermal efficiency of wooden, reinforced concrete, stone, brick walls, facades of foam blocks, as well as prefabricated panels.

- Choosing one or another type of insulation and other materials, it is possible to build “dry” and “wet”, as well as ventilated and non-ventilated facade systems. When warming a frame house, it is enough to take increased stiffness mats, so that they play the role of not only insulation, but also the carrier function.

- It is basalt insulation that is most prevalent when insulating rooms from the inside. They are used for heat and sound insulation of walls, partitions, floors of any design, ceilings.

- Highly demanded material in the conduct of roofing work.It is suitable for thermal insulation of pitched and roofing roofs, attics and attic. Thanks to its fire resistance and wide temperature range of operation, the material is suitable for thermal insulation and thermal protection of chimneys and flues, air ducts.

- Special heat-insulating cylinders based on stone wool are used for insulation of pipelines, heating systems, sewer and plumbing systems.

- Slabs of increased rigidity are used for insulating facades, inside wall “wells” in a three-layer facade system, under a floor screed, and also as an interfloor insulation layer.

Dimensions

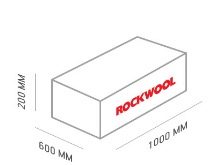

Materials of various applications have different dimensions. Besides, within one ruler there are several size modifications.

- Light Batts plates are produced in the size of 1000 × 600 mm with a thickness of 50 or 100 mm. Standard sizes "Light Batts Scandic" - 8000 × 600 mm, thickness is 50 and 100 mm. There is also a version of the material “Light Batts Scandic XL”, characterized by a large size of plates - 1200 × 600 mm with a thickness of 100 and 150 mm.

- The materials “Venti Batts” and “Optima” have the same dimensions and are available in 2 dimensional versions - 1000 × 600 mm and 1200 × 1000 mm.Plates "Venti Batts N" are produced only in the size of 1000 × 600 mm. The greatest number of overall options has the material “Venti Batts D” - 1000 × 600 mm, 1200 × 1000 mm, 1200 × 1200 mm. Material thickness (depending on the type) - 30-200 mm.

- The dimensions of the plates for a three-layer facade are the same and equal to 1000 × 600 mm. The only difference is only in the possible thickness. The maximum thickness of the Caviti Butts is 200 mm, and the Concrete Element Butts is 180 mm. The minimum thickness is identical and equal to 50 mm.

- Almost all types of slabs for a “wet” facade are available in several dimensional variations. The exception is “Rokfasad” and “Plaster Butts”, having dimensions of 1000 × 600 mm with a thickness of 50-100 mm and 50-200 mm.

- The 3 dimensional modifications (1000 × 600 mm, 1200 × 1000 mm and 1200 × 1200 mm) have the products "Facade Butts Optima" and "Facade Butts D".

- There are also 3 sizes available, but others already have “Facade Butts” slabs (1200 × 500 mm, 1200 × 600 mm and 1000 × 600 mm). The thickness of the product ranges from 25 to 180 mm. "Facade Lamella" has a standard length of 1200 mm and a width of 150 and 200 mm. Thickness ranges from 50-200 mm.

- The dimensions of the materials for thermal insulation of the floor in the screed are the same for both versions and equal to 1000 × 600 mm, thickness ranges from 25 to 200 mm.

- All materials for flat roofs are available in 4 sizes - 2400 × 1200 mm, 2000 × 1200 mm, 1200 × 1000 mm, 1000 × 600 mm. Thickness is 40-200 mm. "Sauna Butts" is produced in the form of slabs 1000 × 600 mm, in 2 variants of thickness - 50 and 100 mm.

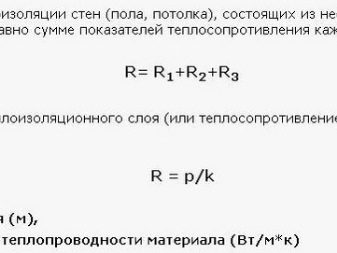

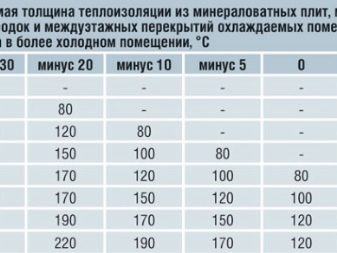

How to calculate the parameters of thermal insulation?

Calculation of insulation parameters is always a difficult process for a layperson. Choosing the thickness of insulation, it is important to take into account many criteria - the material of the walls, the climatic characteristics of the region, the type of finishing material, the specifics of the purpose and the design of the area used.

For the calculation, there are special formulas, it is impossible to do without SNiPs. Leading manufacturers of thermal insulation materials have significantly simplified the process of determining the parameters of thermal insulation, creating special formulas.

One of the best formulas belongs to the company Rockwool. You can use it by specifying in the appropriate columns of the online calculator the type of work, the material of the heat-insulated surface and its thickness, as well as the desired type of insulation. The program in seconds will give the finished result.

To determine the required volumes of heat insulator, calculate the area to be insulated (multiply the length and width). Knowing the area, it is easier to choose the optimal size of insulation, as well as calculate the number of mats or plates. It is more convenient to apply rolled modifications to isolate flat horizontal surfaces.

Insulation is usually purchased with a small, up to 5%, margin in case of damage to the material and taking into account its cutting and filling the seams between the elements of the heat-insulating layer (the joints of 2 adjacent plates).

Tips and tricks

When choosing a heater, the manufacturer recommends paying attention to its density and purpose.

In addition to thermal insulation materials, the company produces waterproofing films and vapor insulating membranes. Recommendations of the manufacturer and user reviews allow us to conclude that for Rockwool insulation it is better to use films and coatings of the same manufacturer. This allows for maximum compatibility of materials.

So, for wall insulation ("Light" and "Scandic") a diffuse vapor-permeable membrane is provided in the usual and processed flame retardant versions. Special vapor barrier Rockwool is used for insulation of the roof and ceiling.

The organization of the "wet" facade will require a special water-dispersed primer "Rockforce"as well as Rockglue glue and Rockmortar adhesive to create a reinforcing layer. It is recommended to finish the primer over the reinforcing layer using a mixture of "Rockprimer KR".As a decorative mixture, you can use branded products "Rockdecor" (plaster) and "Rocksil" (silicone paint for the facade).

For information on how to self-heat a house with Rockwool materials, see below.