Technical characteristics and features of Isobox heaters

"TechnoNIKOL" - one of the most famous manufacturers of thermal insulation materials. The company has been operating since the early nineties, and it focuses on the production of mineral insulation. Ten years ago, the TechnoNICOL Corporation established the Isobox trademark. Thermal plates made of rocks have proven to work perfectly on a variety of objects: from private households to the shops of industrial enterprises.

Special features

Isobox insulation material is manufactured with the involvement of advanced technologies on modern equipment. The material has unique qualities and is not inferior to the best world analogues.It can be used in almost all parts of construction sites. The excellent thermal performance of mineral wool is ensured by the presence of a unique structure. Microfibers are arranged in an unsystematic chaotic manner. Between them there are air cavities that provide excellent thermal insulation. Mineral plates can be arranged in several layers, leaving between them a gap for air exchange.

Isobox heater can be easily mounted on inclined and vertical planes, most often it can be found on such structural elements:

- roof;

- indoor walls;

- facades covered with siding;

- all sorts of floors between floors;

- attics;

- balconies and balconies;

- wooden floors.

The quality of insulation of the company from year to year becomes better, this is noted by both ordinary citizens and professional craftsmen. All the plates are packaged by the manufacturer in vacuum packaging, thereby improving the integrated insulation and safety of products. It should be remembered that moisture and condensate are extremely undesirable substances for mineral heat plates. Their impact detrimental effect on the technical performance of the material.Therefore, the main task is the quality insulation of basalt heat plates. If properly comply with the installation technology, insulation will last a long time.

Kinds

There are several types of Isobox stone wool heat plates:

- "Extralight";

- "Light";

- "Inside";

- "Vent";

- "Facade";

- Ruf;

- Ruf N;

- "Ruf B".

The differences between the insulating plates are geometrical parameters. Thickness can vary from 40-50 to 200 mm. Width of products - from 50 to 60 cm. Length varies from 1 to 1.2 m.

Any insulation company Isobox has the following technical indicators:

- maximum resistance to fire;

- thermal conductivity - up to 0.041 and 0.038 W / m • K at a temperature of + 24 ° С;

- moisture absorption - not more than 1.6% by volume;

- humidity - not more than 0.5%;

- density - 32-52 kg / m3;

- compressibility factor - no more than 10%.

In the products there is a permissible amount of organic compounds. The number of plates in one box - from 4 to 12 pcs.

Technical characteristics "Extralight"

Heaters "Extralight" can be used in the absence of significant loads. The plates are differentiated in thickness from 5 to 20 cm. The material is elastic, fire-resistant, and is able to withstand high temperatures. The warranty period is at least 30 years.

density | 30-38 kg / m3 |

heat conduction | 0.039-0.040 W / m • K |

water absorption by weight | no more than 10% |

water absorption by volume | not more than 1.5% |

vapor permeability | not less than 0.4 mg / (m • h • Pa) |

organic substances that are part of the plates | no more than 2.5% |

Isobox “Light” slabs are also used in structures that are not subjected to high mechanical loads (attic, roof, floor between lags). The main indicators of this variety are similar to the previous version.

Parameters Isobox "Light" (1200x600 mm) | |||

Thickness mm | Quantity in packaging, m2 | Quantity in package, m3 | Number of plates per pack, pcs |

50 | 8,56 | 0,433 | 12 |

100 | 4,4 | 0,434 | 6 |

150 | 2,17 | 0,33 | 3 |

200 | 2,17 | 0,44 | 3 |

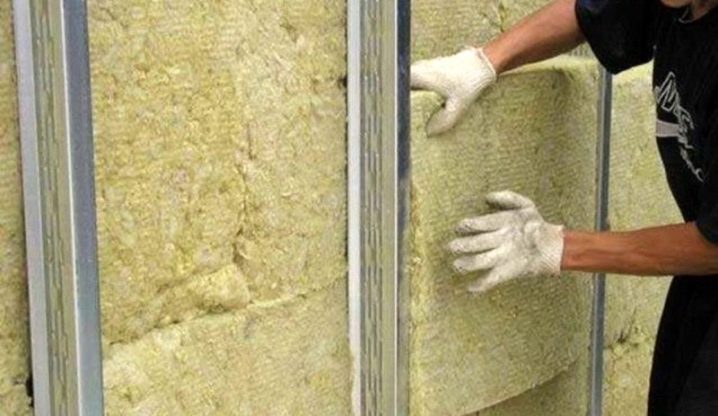

Heat plates Isobox "Inside" are used for indoor work. The density of this material is only 46 kg / m3. It is used to warm the walls and walls where there are voids. Isobox "Inside" can often be found in the lower layer on the ventilated facades.

Technical parameters of the material:

density | 40-50 kg / m3 |

heat conduction | 0.037 W / m • K |

water absorption by weight | no more than 0.5% |

water absorption by volume | no more than 1.4% |

vapor permeability | not less than 0.4 mg / (m • h • Pa) |

organic substances that are part of the plates | no more than 2.5% |

Products of any modifications are sold in sizes of 100x50 cm and 120x60 cm. The thickness can be from five to twenty centimeters. The material is ideal for facade siding.The excellent density of the material allows it to easily withstand significant loads. The plates over time do not deform and do not crumble, they are well tolerated in both heat and winter cold.

"Vent Ultra" is basalt plates, which are used for insulation of external walls with the "ventilated facade" system. There must be an air gap between the wall and the cladding, through which air exchange can occur. Air is not only an effective heat insulator, it also does not allow condensate to accumulate, it eliminates favorable conditions for the appearance of mold or fungus.

Technical characteristics of Isobox "Vent" heater:

- density - 72-88 kg / m3;

- thermal conductivity - 0.037 W / m • K;

- water absorption by volume - no more than 1.4%;

- vapor permeability - not less than 0.3 mg / (m • h • Pa);

- the presence of organic matter - not more than 2.9%;

- tensile strength - 3 kPa.

Isobox "Facade" is used for outdoor insulation. After fixing the basalt slabs on the wall, they are processed with putty. Such material is often used for processing concrete structures, plinths, flat roofs.The material Isobox "Facade" can be processed by plaster, it has a dense surface. Not bad, he showed himself as a heater for floors.

Technical parameters of the material:

- density - 130-158 kg / m3;

- thermal conductivity - 0.038 W / m • K;

- water absorption by volume (assuming full immersion) - not more than 1.5%;

- vapor permeability - not less than 0.3 mg / (m • h • Pa);

- organic matter in the composition of the plates - no more than 4.4%;

- minimum tensile strength of the layers - 16 kPa.

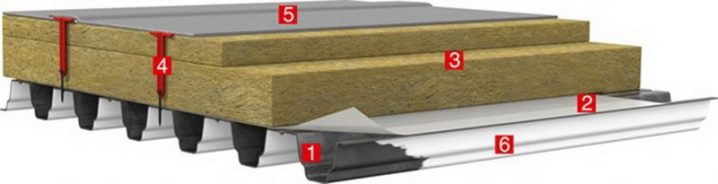

Isobox "Ruff" is usually involved in the installation of various roofs, mostly - flat. The material may be labeled "B" (upper) and "H" (lower). The first type is always present as the outer layer, it is denser and harder. Its thickness ranges from 3 to 5 cm; the surface is undulating, the density is 154-194 kg / m3. Due to its considerable density, Ruff reliably protects against moisture and low temperatures. As an example, consider the Isobox "Roof B 65". This is basalt wool with the highest density possible. It can withstand a load of up to 150 kilograms per m2, has a compressive strength of 65 kPa.

Isobox "Ruf 45" are used as the basis for the roofing "pie".The thickness of the material is 4.5 cm. The width can be from 500 to 600 mm. The length is differentiated from 1000 to 1200 mm. The Isobox “Ruff N” comes in tandem with the “Ruff B”, it is used by the second insulating layer. It is applied on concrete, stone and metal surfaces. The material has a good water absorption coefficient, does not burn. Heat conductivity - 0,038 W / m • K. Density - 95-135 kg / m3.

When mounting the roof, it is necessary to “install” a diffusion membrane, which will reliably protect the roof from moisture penetration. The absence of this important element can lead to the fact that moisture will fall under the material and provoke corrosion.

Advantage of a membrane before PVC a film:

- high strength;

- the presence of three layers;

- excellent vapor permeability;

- possibility of mounting with all materials.

The material in the diffuse membrane is non-woven propylene, free of toxins. Membranes can be "breathing" and "not breathing." The cost of the latter is noticeably less. Membranes are used for ventilation systems, facades, wooden floors. The dimensions are usually 5000x1200x100 mm, 100x600x1200 mm.

Isobox waterproofing mastic is a material that can be used already.The composition is based on bitumen, various additives, solvent and mineral additives. It is permissible to apply the product at temperatures of - 22 to + 42 ° C. At room temperature, the material solidifies during the day. It exhibits good adhesion with materials such as concrete, metal, wood. An average of one kilogram of product is consumed per square meter.

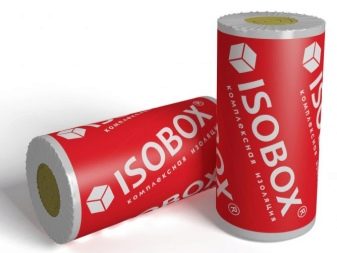

There is also insulation from Isobox in rolls. This product appears under the brand "Teplorol". The material does not burn, they can successfully equip the interior, where there are no mechanical loads.

Width in millimeters:

- 500;

- 600;

- 1000;

- 1200.

The length can be from 10.1 to 14.1 m. The thickness of the insulation is from 4 to 20 cm.

Reviews

Russian consumers note in their reviews the ease of installation of the brand’s materials, their resistance to temperature differences. They also talk about high strength and durability of insulation. At the same time, the price of basalt slabs is low, so many Isobox products are considered among the best on the market.

Tips and tricks

With the help of materials from Isobox several problems are solved at once: insulation, protection, sound insulation. The material of the plates does not interact with solvents and alkali, so it is advisable to use it in workshops with environmentally hazardous industries.The composition of the mineral insulation brand includes various additives that give it flexibility and refractoriness. They also do not contain toxins and serve as a reliable barrier to cold and moisture, and therefore are suitable for residential buildings.

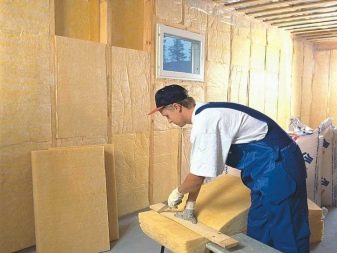

Basalt slabs are stacked in a staggered manner, the joints should overlap. Be sure to use films and membranes. Heat plates are best placed "in thrust", the seams can be sealed with foam.

For central Russia, the thickness of the heat insulation “cake” made of materials from Isobox 20 cm is optimal. In this case, the room is not afraid of any frost. The main thing is to correctly install wind protection and vapor barrier. It is also important that there are no gaps in the joint area (the so-called “cold bridges”). During such a cold season, up to 25% of warm air can “leak” through such joints.

When laying the material between the insulation and the wall of the object, on the contrary, there should be a gap, which is a guarantee that the surface of the wall will not be covered with mold. Such technical gaps should be created when installing any siding or heat plates.Over heat plates often lay rolled insulation "Tepfol". Joints are sealed with foam. On top of Teplofol be sure to leave a gap of about two centimeters so that condensate does not accumulate on it.

Thermal insulation boards with a density of at least 45 kg / m3 are suitable for pitched roofing. A flat roof needs materials that can withstand severe loads (weight of snow, gusts of wind). Therefore, in this case, the optimal choice would be basalt wool 150 kg / m3.

Comparison of insulation Isobox with its counterparts is waiting for you in the next video.