Liquid insulation: the choice of material for insulation inside and out

Under the influence of the harsh climate and adverse weather conditions, residents of most regions of Russia constantly think about the insulation of their living spaces. And for good reason, because the comfort in the house depends on the favorable temperature inside. According to statistics, about 90% of homes do not meet the standards for heat saving. Of course, ultra-modern buildings are being built in accordance with the latest standards of thermal insulation. But the walls of old houses need to be insulated, due to which the heat loss will be reduced to 40%.

The huge choice of building materials in the modern market is impressive and often leads to a dead end, among them it is not easy to navigate even the professionals. Recently, thanks to new technologies, a lot of new heaters with improved technical characteristics have appeared. One of such materials is liquid heat insulation. If you are still thinking about the question of how to insulate your walls, then surely after reading this article you will decide on the choice of insulation material.

Special features

In the construction industry every year there are all new compositions. Insulating paint appeared not so long ago, but has already found its fans, because it is difficult to find a replacement. In addition to facades and walls, it can even insulate your own car and various containers, as well as in the production of agricultural products.

A lot of positive reviews are presented on construction forums about this product, which suggest that this type of thermal insulation is inexpensive, high-quality and easy to use. From the very beginning, the train was developed for the space industry, but later builders became interested in it.

The term "liquid insulation" refers to two different types of insulation: paints with a thermal effect and foam insulation. Each of them has its pros and cons, performance and technical properties.

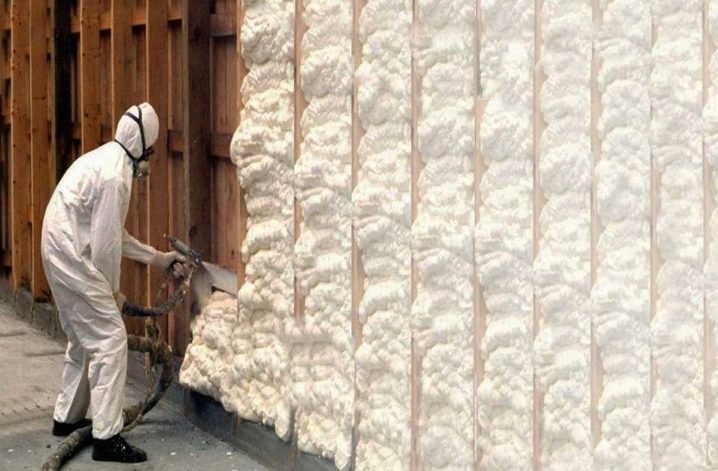

Liquid polyurethane insulation, produced in cylinders, is an innovative class of materials intended for insulation and sound insulation. It is often chosen for finishing difficult areas. With it, even a large area you can warm yourself. Suitable for insulation of structures of any material: metal, brick and concrete, for thermal insulation work in attics and attic.

Liquid ceramic insulation based on ceramic glass is used to warm the walls outside the building, as a result of which natural heat exchange is established, therefore, the building will not cool down in winter and heated in summer. In addition, this kind of insulation will protect the structure from mold, rot and moisture. Thanks to this wall treatment, the cost of heating the house is significantly reduced.

Advantages and disadvantages

The advantages of foamy liquid insulating types of insulation include:

- effective heat loss reduction and heat saving;

- perfectly absorb sounds;

- easy to use, even for users with no experience in construction;

- simple and quick installation;

- high degree of adhesion;

- environmental Safety;

- incombustible;

- low consumption;

- not "loved" by mice;

- do not require special equipment for installation;

- have anti-corrosion and antiseptic properties.

For paints with a thermoelectric effect, we highlight the following advantages:

- the liquid layer does not reduce the area of space, since its maximum layer is no more than 3 mm;

- water repellency;

- decorative effect with metallic luster;

- thanks to latex, liquid insulation is moisture resistant;

- high-quality reflection of the sun's rays;

- heat resistance;

- minimum labor costs during installation;

- no load on the walls;

- increases the life of the treated pipes;

- high speed of processing large areas in a short time.

Liquid insulation - an indispensable thing when insulating hard to reach places.

Among the shortcomings, it should be noted that this type of insulation, such as heat-paint, is not suitable for wooden walls of a bar or log, and its sensitivity to temperature changes during storage and transportation is quite high.

Some buyers point out such disadvantages as high price and limited shelf life of open packaging.

Specifications

For the first time polyurethane insulation was created by German scientists in 1973 based on polyol and polyisocyanate. Now, depending on the composition of additional substances, produce up to fifty different brands of PUF. This type of insulation is superior in many respects to its competitors. Water absorption is characterized by low absorbency, and high adhesion with various surfaces is the main advantage and feature of the foam. Hardening occurs within twenty seconds, and the resulting material will serve at least thirty years.

Thermal paint, or teplokraska in its appearance is no different from ordinary acrylic paint, even in smell. It is easy to apply, spread over the surface with a roller, brush or spray. It is used as insulation for walls inside and outside. Thermal paint insulating components are glass-ceramic, titanium dioxide and latex particles, which impart stability and prevent cracking.It also includes acrylic, which plays the role of the basis of the entire mixture.

Manufacturers claim that liquid ceramic insulation is a completely innovative insulation technology, according to which 1.1 mm thermal layer can replace 50 mm thick mineral wool. This figure is achieved due to the presence of a vacuum thermal layer inside. And the brilliant color of glass-ceramic and titanium derivatives will protect the walls by reflecting infrared radiation. You can associate with a thermos coating.

If you decide to paint the walls of your house, then it is best to immediately choose a thermal paint, so you will kill two birds with one stone - warm the house and give it an aesthetic decorative zest with a metallic sheen.

Also treating the interior or exterior walls of a building with a similar mixture will protect them from corrosion and fungus.

Kinds

Liquid insulation is represented by several types.

Penoizol and polyurethane foam

Both types are included in the group of foams. If you look at them for the first time, you can easily be confused with mounting foam. Important advantages of penoizol are good vapor permeability and low temperature (from +15) solidification, as well as fire safety. It does not burn and does not emit dangerous toxic gases.

Penoizol perfectly fills the voids, while not swelling in volume. However, builders have noted such a minus of penoisol as the formation of cracks, which leads to its shrinkage with time and a decrease in thermal insulation. Another disadvantage is the impossibility of applying by spraying. This type of insulation can be applied only by pouring.

Polyurethane foam is a derivative of polyisocyanate and polyol. For many professionals in the construction business can be a discovery of the fact that liquid insulation based on polyurethane foam produced in two versions: with open and closed voids. This moment has a serious impact on thermal conductivity and vapor permeability. The advantages of this type of thermal insulation are good adhesion to any type of surface, environmental friendliness, low conductivity and resistance to temperature extremes.

Both species are safe for human life and have excellent technical qualities. Is that the difference in price is significant enough - if you can insulate the house inside and out with foam insulation, for an average price, then finishing with polyurethane foam will cost you much more.

Superthin thermal paint

The simplest liquid insulation for walls and floors. Warming this kind of liquid insulation - a very interesting process, similar to the usual painting of the surface. Insulating colorful mixtures have a unique composition and structure, which forms a thin thermal film.

Due to the fact that the film is very thin, insulation is produced in several stages.

Separate attention deserve teplokraski on the basis of ceramics, which upon drying form a ceramic crust. It is possible to apply this structure everywhere and in any way convenient to you: with a brush or spray.

Manufacturers and reviews

The market already has a sufficient number of domestic and foreign manufacturers of liquid insulation.

Main manufacturers:

- Isollat;

- "Teplokor";

- "Tesolat";

- Astratek;

- "Thermosilat";

- Alfatek;

- "Keramoizol";

- Thermo-Shield;

- Polynor.

The most sought-after creators of liquid insulation are the firms Corundum, Bronya, Astratek.

Reviews of liquid insulation "Astratek" they say that it is one of the best materials of the modern market, which is characterized by anti-corrosion properties and is able to withstand temperatures up to +500 degrees.The composition of thermal insulation based on polymer dispersion and special fillers is a homogeneous mass, similar in consistency to the mastic, which is easy to apply with a brush or spray. Products from "Astratek" high quality and safe.

When applying means "Astratek" apply special brushes and sprays, which will easily allow you to do the work with your own hands.

The minimum isolation service is fifteen years, but if all the norms of exploitation are observed, the period is extended to 30 years minimum.

Highly functional ultra-thin liquid ceramic insulation from “Korund” is a modern coating, which is presented in a wide assortment on the market of any city in Russia.

"Korund" offers several types of insulation at once:

- "Classic" for processing walls and facades, as well as pipelines;

- "Winter" used to protect surfaces at sub-zero temperatures;

- "Antikor" used for processing areas prone to rust;

- "Facade" - special composition for exterior walls and facade.

Domestic products of the firm "Bronya" is also divided into several modifications: "Classic", "Antikor", "Winter" and "Facade" - everything, like the company "Korund". Also presented "Volcano" - a mixture capable of withstanding temperatures above 500 degrees.

Norwegian Polynor on the basis of polyurethane, it became known in Russia quite recently, but in such a short time it deserved the love of builders due to the fact that it can be used on any surface, and using special nozzles spraying is carried out without problems even in hard-to-reach places. Lack of seams reduces heat loss. Polynor product is lightweight and environmentally friendly.

The average price of manufacturers is about 500-800 rubles per liter of liquid waterproofing.

How to choose a quality product?

In order not to be mistaken in the choice, having spent money for nothing, you need to choose quality products for use in insulation. The lower the density of the coloring mixture, the higher its beneficial thermal insulation properties will be.

After mixing a good heatpaint, knead the droplet between your fingers. If the surface is rough due to the presence of a large number of microspheres, it means that there is no doubt about the quality of the selected product.

Recommendations for use

Warming with liquid insulants is a fairly simple procedure, which is carried out in several stages and is somewhat similar to staining with paint and varnish compounds. Before starting work, measure the total area of the room and purchase the required amount of thermal paint.

When purchasing, keep in mind that for better heat saving you will have to cover the surface several times. Depending on the conditions and climate of the residence, it may be necessary from three to six layers of paint.

Choosing a specific manufacturer, focusing on customer reviews and tips installers professionals.

Prepare the surface for applying the mixture, clean from dust, dirt, putty and seams with a putty. To improve adhesion, treat the cleaned surface with a primer. The paint will never stick to dirty walls, there may be detachment or leakage. It is necessary to perform work only in good and dry weather conditions.

The first layer is applied as a primer. The final polymerization time is approximately one day.

You can also use liquid insulation over a putty,a after applying it is possible to trim wallpaper or ceramic tiles.

It is possible to apply liquid-ceramic insulation using an airless sprayer or a special roller. The roller should have an average pile length, so it will grab more paint at a time. Do not forget to mix the composition thoroughly with a construction mixer before use. Do not allow passes, paint the wall in small areas. The corners of the house and other hard-to-reach spots are stained with a brush.

We apply the following layer only after full drying previous. If you applied the first layer with horizontal movements of the roller, then the next one should be painted with vertical ones. Thus, you enhance the warming.

Sandwich technology can be used to isolate very hot pipes. This practice involves a fivefold alternation of layers of a liquid-ceramic coating with layers of fiberglass. If you want to get a perfectly smooth surface, then apply a regular bandage or gauze to the finishing layer and cover it with technical varnish KO85.

Recently there has been a great demand on the market for foamy liquid insulators and equipment for their use.In terms of the complexity of installation, liquid foam insulation is different from mineral wool and other materials for the better. The whole process can be accomplished alone, without help. For example, comparing with rolled or block heaters, foam allow for installation in a short time, in just a few hours. And in financial terms, they also significantly benefit.

The principle of operation is simple: after you have prepared the surface, spray foam from top to bottom. The flow rate is adjusted by lowering the valve on the mounting gun. The thickness of the layer should not exceed five centimeters.

Useful tips

- When working with thermal paints, be sure to wear a respirator. It is very easy to inhale in pairs, despite the fact that the paint dries very quickly.

- Before applying the foam insulation in the balloon, shake it for three minutes.

- Polyurethane insulation when applied can cause irritation of the eyes and skin, so use special construction glasses and a protective suit.

- The better you align the surface of the coating, the better the insulation will be and the less material will go.

- Prepare the heat-insulating mixture of thermal paint immediately before use. Mixing repeat every half hour, do not let the paint splitting.

- Some formulations having a thicker consistency, if necessary, diluted with plain water.

- If you use foam insulation to isolate the holes, then before starting to fill the space, run a jet of air from the compressors in the slots and check for any "dead" zones.

- Always work from the top down.

- When insulation is possible to combine several insulation materials. For example, walls can be insulated with mineral wool, hard-to-reach places to fill with penoizol, and paint the floors with liquid ceramics.

- Upon completion of work with polyurethane-based insulation, the installation gun must be cleaned with a liquid solvent.

- Uncured foam can be immediately washed off with water.

- If you want to insulate the facade, it is better to choose liquid insulation labeled "Facade" from the company "Corundum" or "Armor", which are designed specifically for exterior wall decoration.

- Each manufacturer specifies instructions with recommendations for application on the package.Strictly follow all the instructions given so as not to break the technology.

- When choosing insulation, focus on your financial capabilities, as well as on the principle of operation.

- Assess your strength and resources. If you are not sure that you can do it, then rely on the specialists, so as not to waste time and money in vain.

For information on how to use liquid insulation, see the following video: