Isoroc Insulation: Features and Applications

The top list of the best modern insulation materials, along with European heaters, includes Isoroc products from Russia. Appearing on the market in 2000, this company was able to quickly gain the trust and respect of professional and novice builders. Evidence of this - the company's entry into the international concern Saint-Gobain, which is a leader in the production of building materials and the development of innovative technologies in the construction industry.

Production features

Modern insulation Isoroc is made of basalt or gabbro technology, developed in Germany, on the equipment of the Swedish company Ungers.

The process of creating a heat-insulating material consists of several stages:

- Under the influence of high temperatures (up to 1500 ° C) the rock is melted.

- The melt is placed in a centrifuge, in which it is stretched in the "thread".

- The obtained fibers under the influence of air masses are moved into the fiber deposition chamber, in which dedusting and water-repellent components are added to them.

- The processed basalt fiber enters the apparatus, where it is distributed and firmly weave individual threads together. When interlacing, the fibers are arranged in different directions to increase the strength of the web.

- Subsequently, the resulting material is pressed under high pressure and again subjected to heat treatment. Heating up once again, the fiber polymerizes, forming a material that is resistant to mechanical damage (breaks, cracking).

- Ready insulation is cut into plates or mats and placed in shrink packaging.

In the production process, everything is taken into account: from the quality of raw materials to the exact observance of the proportions of components and technologies. At all production stages, constant monitoring of dozens of different parameters is carried out, which guarantees the exceptionally high quality of each production batch.

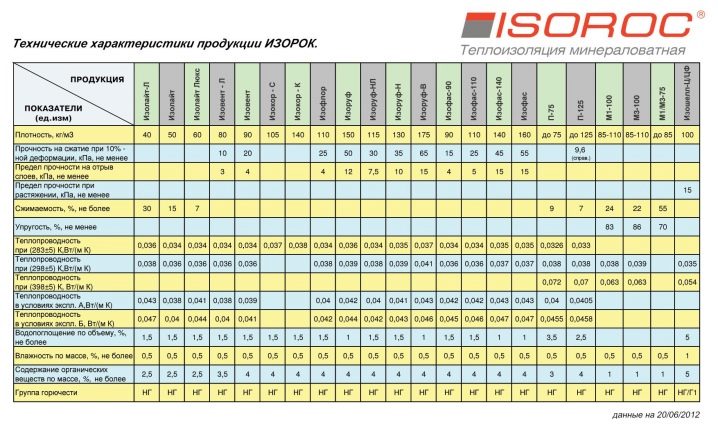

Technical characteristics of insulation

Due to its composition and manufacturing technology, Isoroc heaters acquire the following technical characteristics:

- High density, which affects the strength of the material and its resistance to deformation. Depending on the density, the scope of use of the material is determined, and its cost changes.

- Compressibility indicators - from 2 to 20%.

- Thermal conductivity varies in the range of 0.04-0.042 W / mK, so that the material retains heat well. This effect is achieved due to the large number of air pores formed in the material during the production process.

- Good vapor permeability allows to avoid the accumulation of condensates inside the room and the formation of mold.

- Fireproof. Stone fibers of a heat insulator do not ignite even when in contact with open fire and can withstand a temperature rise of up to 1000 ° C.

Different models of insulation characteristics differ, but all products always contribute to:

- improvement of the microclimate in the interior;

- significant improvement in heat and sound insulation properties;

- reduce the load on the foundation of the building (foundation).

In addition, the use of any model Isoroc reduces the cost of repairs.

Advantages and disadvantages of the material

Compared with most insulants, basalt insulation from Isoroc has a number of advantages, including:

- high hydrophobicity;

- good resistance to external negative influences (mechanical and natural);

- ease of installation and operation;

- environmental friendliness;

- low weight

In addition, it does not deform, does not wrinkle over time, microorganisms do not breed on it, and insects with rodents prefer to stay away from it. Due to all this, basalt insulation has a long service life and does not require replacement for a long time.

As for the shortcomings, then they can be attributed only to the relatively high cost of the material.

Scope of application

The mineral wool of the brand Isoroc has found application in the performance of a large range of construction and repair work. Most often it is used for:

- roofs (both flat, and cattle);

- garret and basement floors;

- walls inside the house;

- external facades (under plaster or on ventilated hinged facades);

- sex;

- sandwich panels or three-layer structures made of concrete;

- industrial equipment and pipelines.

High quality and a wide range of insulation can be used in large and low-rise private construction.

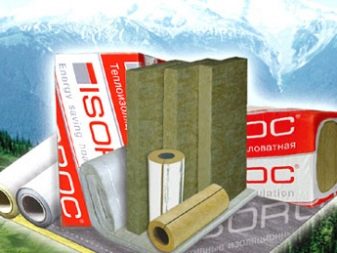

Types of insulation Isoroc

The range of the company presents several options for insulation. The most popular and popular ones are:

- Isolight and its modifications. This type of heat-insulating material is intended for warming horizontal, vertical, inclined surfaces of any type. It is suitable for use on frame walls, interfloor ceilings, in three-layer masonry, ventilated facades. Plates of ordinary insulation Isolight have a density of 50 kg / m3 and are considered the most optimal option for low-rise private construction. In addition, the model range includes mineral wool boards with a density of 40 kg / m3 (Isolight-L) and 60 kg / m3 (Isolight-Lux). At different densities, all materials in this series have similar characteristics. Thus, the rate of water absorption of any of these heaters, even with prolonged exposure to moisture, does not exceed 1 kg / m2, and the thermal conductivity varies from 0.33 to 0.40 W / (m.K) depending on the operating conditions.

- Ultralight - one of the novelties in the series of thermal insulation materials. The main distinctive feature of this type of insulation is its reduced density - 33 kg / m3. In this case, the manufacturer offers plates with a thickness of 100 mm and 50 mm. The rest of the operational standards Ultrlight practically do not differ from the previous series insulation.

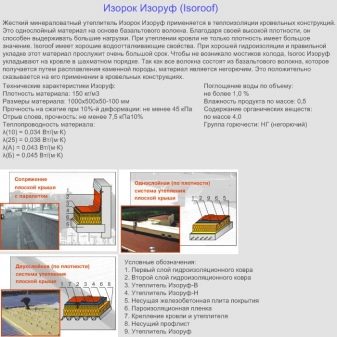

- Isoroof - the material intended for thermal insulation of a flat roof from a steel professional flooring and interfloor overlappings. It can be laid both on top of the cement screed, and directly on the concrete or RC base. This type of insulation has an increased density - 150 kg / m3, thickness from 40 to 130 mm. At the same time, it is quite elastic, easy to handle, inert to chemicals and is not susceptible to biological effects (mold, rot). In this series are also presented modifications marked Isoroof-B (Isoroof-T), -N (Isoroof-B), -NL (Isoroof-BL). From each other, they differ in density and are used to create a two-layer thermal insulation system.

- PP 75 and PP 125 - materials suitable for insulation of buildings, structures and insulation of industrial equipment, the surface of which can be heated to + 400 ° С.The first type has a lower density (up to 75 kg / m3), but has greater flexibility, which allows it to be used on curved surfaces (for example, pipelines). Insulation with marking PP 125, in turn, bends and changes shape much more difficult, but it has a density of 12 kg / m3 and a strength of at least 10 kPa.

- Isovent - refractory plates, most often used to isolate saunas and baths. Kashirovanny aluminum foil, metal mesh or fiberglass fabrics, when installing it does not require the use of additional polymer membranes. In addition to the basic insulation, the series contains modifications of SL and L. The main difference between the models from each other is density. The highest rate - 90 kg / m3 - has Isovent. At the same time, basalt-fiber plates of this type may have a reduced thickness of 40 mm. As for the other modifications, their thickness parameters vary in the range of 50-170 mm. Insulation density with SL marking is 75 kg / m3, and L - 80 kg / m3.

- Isofloor - one of the best options for installation on interfloor overlappings and a floor. It can be laid under the cement screed and self-leveling floors. Also suitable for insulation sandwich panels with a sheath of metal.At a density of 110 kg / m³, mineral wool boards of this type have increased strength, which allows them to withstand significant loads without deformation and loss of their performance characteristics.

All Isoroc mineral wool boards are sold in packs of 4 or 8 sheets. The weight and dimensions of the package depend on the density and dimensions of the insulation itself.

Installation rules

The quality of insulation with basalt mineral wool Isoroc depends largely on how they were installed. Therefore, non-professional and novice repairmen for the installation of insulation It is worth taking the advice of experienced craftsmen:

- For the fixing of the plates, special adhesive compositions and dish-shaped dowels are used.

- In order for the construction to be as strong and durable as possible, for laying insulation it is necessary to build a frame made of a metal profile or wooden bars.

- If it is necessary to cut a slab of basalt fibers, an assembly knife is used. At high density and thickness of the material, the knife is replaced with a hacksaw.

The process of laying insulation consists of several stages:

- Installation of metal or wooden frame.For this, the profile or bars are fixed in a strictly vertical position. The distance between the supports depends on the width of the mineral wool plate - the insulation must be tight between them.

- On the stone surfaces, Isoroc plates are fastened with nails at the rate of 5-6 dowels per 1 m2. In other cases, glue is used for fastening.

- A windproof membrane is laid over the basalt wool, all joints of which are carefully glued with adhesive tape.

When warming a roof, floor or facade, the installation rules may differ slightly. An important condition for laying insulation is the presence of a ventilated gap between it and the exterior. It is necessary so that the moisture retained by the vapor barrier film is not absorbed into the finishing materials.

Reviews

The popularity and high quality of insulation brand Isoroc show numerous customer reviews.

Most of those who insulate their homes with mineral wool plates of this manufacturer, highly appreciate the insulating qualities of the material. At the same time, they note that after installing basalt insulation plates, even at low external temperatures, energy consumption is significantly reduced, as the air in the room heats up faster and stays warm longer.

Also, when using basalt fiber insulation inside the room, steam does not accumulate, which not only improves comfort, but also prolongs the service life of finishing and other building materials.

Along with the operational qualities of the material, the ease of transportation and installation of insulation deserve high marks.

Review the Isoroc insulation in the next video.