Insulators Isover: a review of thermal and sound insulation materials

The building materials market is replete with various insulants and soundproof materials for buildings. As a rule, the main difference between them is the form of manufacture and the composition of the base, but also a significant role is played by the country of manufacture, manufacturer's reputation and applicability.

Insulators usually cost a significant amount, so in order not to be lost, you need to rely on guaranteed high-quality goods, for example, products from Isover.According to experts and customer reviews, it occupies a leading position in such characteristics as service life, reliability and efficiency.

Special features

Isover insulation is used both in residential buildings and in public institutions and industrial buildings. The production and sale of this product is engaged in a company that is a member of the international association Saint Gobain. - one of the leaders in the construction materials market, which emerged more than 350 years ago. Saint Gobain is known for its innovative developments, the use of modern technologies and the high quality of its products. All of the above items also apply to Isover heaters, produced in various versions.

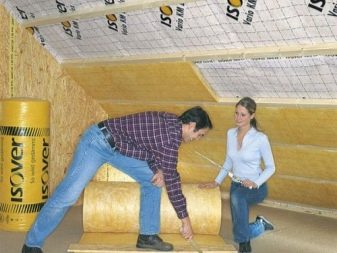

Isover products in many respects have pros and cons of mineral wool, as they demonstrate similar properties. They are marketed on the market in slab format, rigid and semi-rigid, and mats rolled into rolls according to their own patented technologies in 1981 and 1957. This insulation is used for the treatment of roofs, floors, facades, ceilings, floors and walls, as well as ventilation pipes. The basis of Isover are glass fibers.Their length ranges from 100 to 150 microns, and thickness - from 4 to 5 microns. This material is resilient and resistant to stress.

Isover insulators are tearproof, which means that they can be placed on structures of complex shape. For example, these include pipes, elements of production lines, industrial equipment and others.

When using Isover as a heater or sound insulation, it must be protected from moisture.

Usually used for this vapor barrier and waterproofing film. The steam insulator is usually mounted from inside the house to protect it from condensation. Waterproofing film is placed outside, saving from rain and melting snow. As a rule, Isover is mounted without the use of fasteners, the only exception can be the insulation of the ceiling - in this case dowels are used - “fungi”.

Under the "header" of the brand is produced a mass of insulators, which have different purposes and perform various functions. They are divided into two groups: for industrial and residential use. In the private housing construction the most commonly used material is “Classic”, marked with the letter “K”.

The price of Isover insulation may vary in different regions of our country. Typically, the average varies from 120 to 160 rubles per square meter. In some areas it is more profitable to purchase it in packages, and in some areas in cubic meters.

Subtleties of manufacture

Saint Gobain has been working in the Russian market for over 20 years and has been producing materials at two plants: in Yegoryevsk and Chelyabinsk. All enterprises are obliged to undergo certification of the international environmental management standard, which makes Isover insulation a non-polluting product, which by their ecological characteristics are at the same level with cotton and flax.

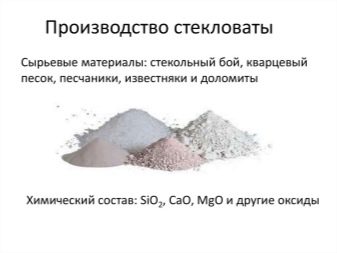

As a part of different types of Isover are both glass and basalt fibers. Such a structure is the result of the processing of glass pitting, quartz sand, or the mineral rocks of the basalt group.

- It is in Isover that minerals are used. Its components melt and stretch into fibers, following TEL technology. The result is a very thin thread, which are interconnected with a special composition of resins.

- Pre-mix the composition of broken glass, limestone, quartz sand and other minerals.

- To obtain a homogeneous fluid mass, the resulting mixture must be melted at a temperature of 1300 degrees.

- After the "liquid glass" falls on a rapidly moving bowl, in the walls of which holes are made. Thanks to physics, mass flows out in the form of threads.

- In the next step, the fibers must be mixed with a glue from polymers with a yellow tint. The resulting substance enters the furnace, where it is blown with hot air and moves between the steel shafts.

- The glue sets, the layer is leveled and glass wool is formed. It remains only to send it under the circulating saws to cut into fragments of the desired size.

When buying Isover you can see the certificates of quality. When the material is produced under license, the seller provides documents confirming the standards EN 13162 and ISO 9001. They become a guarantee that Isover is made of safe materials and there is no prohibition on its use indoors.

Species

There are different types of insulation, depending on whether they are implemented in a roll format or in plates. Both varieties can have different sizes, different thicknesses, and different styling technology.

Insulation is divided and depending on the application. They are universal or suitable for individual areas - walls, roofs or saunas. Often the purpose of the heater is encrypted in its name. In addition, it is worth adding that the materials are divided into those used indoors and on the facades of buildings.

It is also worth adding that Isover is classified by the stiffness of the material. This parameter, relating to the characteristics of GOST, is indicated on the package and is closely related to the density, the degree of compression in the package and the thermal insulation properties.

Advantages and disadvantages

All Isover heaters have similar positive and negative characteristics. If we talk about the pros, then there are the following:

- The material has a low thermal conductivity. This means that the heat “lingers” in the room for quite a long time, so it is possible to spend smaller amounts on heating, thereby saving significant amounts.

- Insulation demonstrates a high ability to absorb noise due to the presence of an air gap between the fibers, absorbing vibrations. The room becomes as quiet as possible, protected from external noise.

- Isover has a high level of vapor permeability, that is, the material breathes.It does not trap moisture and the walls do not begin to melt. In addition, the dryness of the material increases its service life, because the presence of moisture adversely affects thermal conductivity.

- Heat insulators are not flammable at all. On a scale of flammability, they received the highest rating, that is, the best resistance to fire. As a result, Isover can be used to build wooden buildings.

- Plates and mats are lightweight and can be used in buildings that do not tolerate excessive load.

- Service life can reach 50 years.

- Insulation treated with compounds that increase moisture resistance.

- Material is easy to transport and store. The manufacturer squeezes Isover 5-6 times when packed, and then it completely returns the form.

- There are product lines with different technical characteristics, designed for different areas of construction.

- Isover has a high elasticity. Insulation surpasses other mineral wool in this indicator due to the special technology TEL, on which it is produced.

- 5 centimeters of mineral wool are equal in thermal conductivity to 1 meter of brickwork.

- Isover is resistant to biological and chemical effects.

- Isover has an affordable price, especially comparing it with other alternatives.

- The material shows high density and rigidity, which allows it to be mounted without additional fasteners.

However, there are still some minuses:

- A relatively complex installation process, during which it is necessary to additionally protect the respiratory organs and eyes.

- The need to lay an additional layer of waterproofing during construction. Otherwise, it will absorb moisture, which will violate the insulating characteristics. In winter, mineral wool may even freeze, so it is important to leave a ventilation gap.

- Some species still do not belong to non-combustible, but to self-extinguishing - in this case, you will additionally have to comply with the requirements of fire safety.

- The soft structure of wool limits the scope of application.

- The only negative for industrial enterprises is that when the temperature rises to 260 degrees, Isover loses its properties. Namely, there such temperature is quite possible.

Specifications

Isover is manufactured using special patented TEL technology and has excellent technical characteristics.

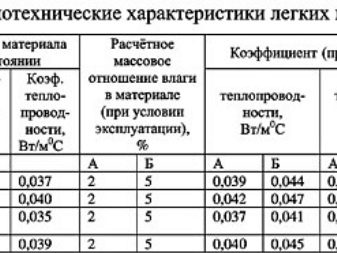

- Coefficient of thermal conductivity very small - only 0.041 watts per meter / Kelvin.The big plus is the fact that its value does not increase with time. Insulation retains heat and retains air.

- As for sound insulation, indicators for different models differ, but always at a high level. This means that any kind of Isover will somehow protect the room from external noise. All this is ensured by the air gap between the glass fibers.

- As for the flammability, the Isover species are either non-flammable, or slightly flammable and self-extinguishing. This value is determined by the relevant GOST and means that the use of almost any Isover is absolutely safe.

- Vapor tightness This insulation ranges from 0.50 to 0.55 mg / mchPa. When moisture insulation at least 1% will immediately deteriorate the insulation by as much as 10%. To prevent this from happening, it is necessary to leave a gap of at least 2 centimeters between the wall and the insulation for ventilation. Glass fibers will return moisture and thereby maintain thermal insulation.

- Isover can serve up to 50 years and for a rather impressive period, do not lose their insulating qualities.

- In addition, the composition of the heater are water repellent components, making it inaccessible to mold.

- It is also important that in fiberglass material no bugs will be able to live and other pests. In addition, the density of Isover is approximately 13 kilograms per cubic meter.

- Isover considered eco-friendly insulation and absolutely safe for human health.

- It is much easier than competitors., therefore, it can be used in rooms made of fragile materials or in which the creation of excessive load is prohibited. The thickness of a single-layer Isover can be either 5 or 10 centimeters, and in a two-layer layer, each layer is limited to 5 centimeters. Slabs are usually cut to meter by meter, but there are exceptions. The area of one roll varies from 16 to 20 square meters. Its standard width is 1.2 meters, and the length can vary from 7 to 14 meters.

Recommendations for use

The company Isover produces not only universal insulation, but also a narrow action, responsible for specific elements of the building. They differ in size, functions and technical properties.

Isover can be released for light insulation (wall and roof insulation), general insulation (soft plates for frame structures, medium-hard plates, mats without fasteners and mats with foil on one side) and special purposes (for pitched roofs).

Isover has a special label where:

- KL are slabs;

- KT - mats;

- OL-E - special hardness mats.

The numbers also show the thermal conductivity class.

The packaging also indicates where you can apply one or another type of insulation.

- "Isover Optimal" It is considered a universal material, which is used for processing of floors, walls, partitions, roofs and floors along logs - that is, all parts of the house, except the foundation. The material has a low thermal conductivity and retains heat in the house, it is elastic and non-flammable. Installation is very easy, does not require additional fasteners, and, given the versatility, all of the above points make the "Optimal" one of the most popular representatives of Isover.

- "Isover Profi" also is a universal insulation. It is implemented in the form of mats rolled into rolls, and is used for roofs, walls, ceilings, ceilings and partitions."Profi" has one of the lowest thermal conductivity and is very convenient to cut. Insulation can be 50, 100 and 150 mm thick. As well as "Optimal", "Pros" refers to the class of combustibility NG - that is, it is absolutely safe in a fire situation.

- "Isover Classic" chosen for thermal and sound insulation of almost all parts of the house, except those on which falls the greatest load. The “exceptions” include the base and plinth. The material is sold in rolls and plates and has a low rigidity. The porous structure makes it an excellent insulator. However, this type does not differ in strength and durability, and therefore, is not suitable for installation under the screed and for finishing walls under plaster. If, nevertheless, there is a desire to use it for warming the facade, it is only in combination with siding, wall paneling or front panels mounted on the crate. "Classic" very well warms the house and reduces the cost of heating almost twice. In addition, it is a good sound insulator and protects the structure from excessive noise.

- "Isover Warm Home-Cooker" and "Isover Warm Home" used in the installation of most parts of the house. They have almost identical technical characteristics with the exception of volume and linear dimensions.However, it is customary to use plates in one sphere, and mats in another. "Warm House-Slab" is chosen for insulating vertical surfaces, inside and outside the house, as well as frame structures. “Warm house”, realized in the form of rolls of mats, is used for insulating interfloor ceilings and the floor above the basement (the installation is between lags).

- "Isover Extra" It is made in the form of plates with enhanced elasticity and a 3D effect. The latter means that after compressing the material expands and occupies all the free space between the surfaces requiring insulation. The plates are tightly interconnected and also fit snugly to the surfaces. "Extra" is also universal, but is usually used for wall insulation indoors. It should be added that it can also be used for thermal insulation of facades in case of subsequent plating with brick, clapboard, siding or panels, and for roofs. "Isover Extra" is considered one of the most effective materials for heat preservation.

- "Isover P-34" Available in the form of plates, the thickness of which can be 5 or 10 centimeters. They are mounted on the frame and are used to isolate the ventilated parts of the house - the facade or multilayer masonry.It is possible to warm both vertical, and horizontal, and inclined surfaces, since the model is very elastic. "P-34" is easily restored after deformation and resistant to shrinkage. It is completely non-flammable.

- "Isover Frame P-37" It is used for insulation of floors between floors, roofs and walls. It is important to consider that the material should fit snugly to the surface. "Isover KT37" also fits snugly to the surface and is used for insulating floors, partitions, attics and roofing.

- "Isover KT40" refers to the two-layer materials and is implemented in the form of rolls. It is used exclusively on surfaces arranged horizontally, that is, for ceilings and floors. In case of insufficient depth of the cavity, the material is divided into two separate layers of 5 centimeters. The material has a high vapor permeability and refers to non-combustible materials. Unfortunately, it cannot be used on surfaces with a complex wet mode of operation.

- "Isover Styrofoam 300A" requires mandatory fasteners and is available in the form of plates. The material has a high moisture resistance and thermal insulation due to the presence of extruded polystyrene foam in the composition. Walls inside and outside the room, floor and flat roof are treated with such insulation.Over plastering is possible.

- "Isover Ventiterm" has a somewhat unusual scope. It is used for ventilated facades, pipes, water supply, as well as to protect precision instruments from the cold. It is possible to work with it both when using fixture, and without it. This insulation is produced in the form of plates. The technical characteristics of it are quite serious, especially in terms of strength - an order of magnitude better than that of ordinary mineral wool.

- "Isover Frame House" it is used for insulation of walls outside and inside, pitched roofs and mansards, as well as floors and partitions. In general, it is suitable for improving any frame structures in the house. The elasticity of the material helps to maintain shape during operation and installation, and stone wool fibers provide additional protection against noise.

Roofing

Some universal Isover varieties are used for warming roofs, for example, "Optimal" and "Profi", as well as highly specialized - "Isover Warm Roof" and "Isover Pitched Roofs and Mansards". Both materials are designed for the same purpose, but have different characteristics: they differ in the form of release, linear dimensions and the material used.They also undergo special treatment, which gives the products increased moisture resistance.

- "Warm roof" produced in the form of mats rolled up in rolls. They are sold in plastic packaging with markings that allow cutting the material along its width. "Pitched roofs" are realized in the form of plates, pressed and packed in polyethylene. They are used in the case of insulation of pitched and mansard roofs, as well as for surfaces inside and outside the building.

- "Isover Pitched Roof" used exclusively for thermal insulation of the roof. It is moisture resistant, does not transmit sounds, has high vapor permeability and is not combustible. As a rule, it is recommended to use it in two layers, and the top closes the joints of the bottom - so the material will be even better to keep warm. "Skatnaya Roof" is produced in the form of slabs with a width of 61 cm and a thickness of 5 or 10 centimeters. "Pitched Roof" has a high hydrophobicity - it does not absorb moisture, even if you immerse it in water for a long time. This allows you to use the material in difficult conditions, not suitable for other heaters.

- "Isover Ruf N" is a heater for a flat roof.It has the highest level of thermal protection and is compatible with any building materials.

- "Isover Master of Warm Roofs" also has a high rate of thermal protection. Due to vapor permeability, it eliminates the accumulation of moisture in the wall. In addition, when insulated outside the stove will retain its properties in any weather.

- "Isover OL-P" - This is a special solution for a flat roof. It has ventilated grooves for removal of moisture and was created using the thorn-groove technology, which increases the tightness of the mineral wool layer.

Facade under plaster

The following Isover varieties are used to insulate the facade in order to further coat it with plaster: Facade Master, Plaster Facade, Facade and Facade Light. All of them are realized in the form of plates and are non-combustible material.

- "Facade Master" pIt is used for warming facades of residential buildings up to 16 meters high. The plaster should be applied with a thin layer.

- "Plaster Facade"being an innovative material costs much less than the previous one, but performs the same functions and is applied under the same conditions.

- "Facade" it is applied at the subsequent covering with decorative plaster.

- "Facade Light" used for houses with a small number of floors and for subsequent finishing with a thin layer of plaster. For example, this option is chosen by the owners of country houses. Such a material is durable, is stiff, but has a small weight.

For soundproofing buildings

In order to protect the house from various noises, both external and internal, “Isover Silent House” and “Isover Sound Protection” are used. Besides, You can use the universal heaters - "Classic" and "Profi".

- "Quiet House" has a high ability to absorb noise, so it is often chosen for sound insulation of walls and partitions between rooms. Also, plates are used for horizontal surfaces - for lags, beams, the spaces between the suspended ceiling and the original one. The material has two functions, so the home becomes quiet and warm.

- "Sound Protection" It has a high elasticity, therefore it is often mounted inside a frame obreshetka, which acts as a partition or is fixed on the wall (in the case of facade coatings). The material can be used in combination with other heaters and thereby create a double layer - which retains heat and does notskipping sounds. Particularly effective such a solution will be to create frame partitions and attic floors.

Wall insulation inside

Isover Profi, Isover Classic Stove, Isover Warm Walls, Isover Heat and Quiet Wall and Isover Standard are recommended for thermal insulation and sound insulation of the walls inside and outside the buildings. These heaters are realized both in mats in rolls, and in the form of sawing.

- "Standard" usually selected for thermal insulation structures consisting of multiple layers. In this case, siding, wall paneling, brick, block house and other materials can be used as finishing. In addition, these plates are suitable for thermal insulation of frame structures, for the attic and sloping roofs. Due to its medium density, the material is not suitable for further plastering of walls. "Standard" has good elasticity, which means a tight fit to the surfaces and structures. Plates are fixed when using special clamping mounts.

- "Warm walls" - These are plates that are also made of glass fibers, but in addition are reinforced with water-repellent treatment. This version is also used for thermal and sound insulation of walls inside and outside, installation in the frame, insulation of roofs, loggias and balconies.Increased moisture resistance becomes an added plus in the last two examples. The material is elastic and elastic, does not slip and does not break.

- "Warm and Quiet Wall" it is realized both in the form of plates, and rolls. The material has a porous structure that allows it to perform two functions. In addition, this type is characterized by high vapor permeability and “breathes”. This allows you to create a comfortable living environment. The plates are elastic and they do not even need to be additionally fixed - they themselves will “creep apart” within the framework.

- "Warm and Quiet Wall Plus" It has similar characteristics with “Heat and Quiet Wall”, which will be discussed later, but it has lower thermal conductivity and better sound insulation. Slabs are used for walls inside the building, walls outside under the siding or facade coatings and, if there is additional protection, for the insulation of frame structures.

Floor insulation

In order to properly insulate the floors, you can choose two specialized materials - “Isover Flora” and “Isover Floating Floor”, which have slightly different technical and operational characteristics, which, however, combine damping properties and mechanical characteristics.Both types are easily mounted, but using different technologies. In addition to insulation, these materials are also different high-quality two-way soundproofing.

- "Flor" used for the construction of floating floors and structures for logs. In the first case, the material covers the entire surface and creates a warm and quiet floor. Due to the adaptation to high loads, the insulation can be placed under the concrete screed.

- "Floating floor" always used to create a concrete screed, which will not be connected with the walls and the base, in other words, for the "floating" floor. Plates are always laid out on a perfectly flat surface and are connected according to the method, called the “thorn-groove”. Due to the fact that the fibers are arranged vertically, this kind of insulation demonstrates outstanding strength characteristics.

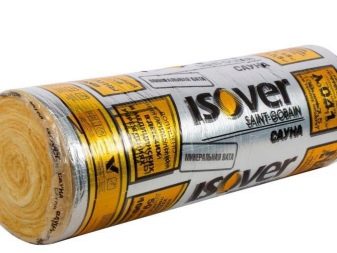

Thermal insulation bath

For warming baths and saunas, Isover has special solutions - mats, rolled up and called “Isover Sauna”. This coating has a foil layer on the outside, which reflects the heat and creates a vapor barrier.

"Sauna" consists of two layers. The first is a mineral wool, based on fiberglass, and the second - foil. It is worth noting that mineral wool is a non-combustible material, and the foil coating has a flammability class G1. It can withstand temperatures up to 100 degrees due to the presence of glue, and at higher temperatures it can ignite and decay on its own. In order to avoid an accident, the foil layer is additionally covered with clapboard.

"Isover Sauna" on the one hand serves as thermal insulation, and on the other - is a barrier to steam so that the mineral layer is not affected by a large number of fumes. Foil reflects heat from the walls in the room and increases the level of heat retention.

The nuances of editing

The first thing you need to choose the right type of Isover, for this it will be enough just to look at the available labeling. Each product is assigned a class and number of stars, and this data is contained on the packaging. The more stars, the better the heat-shielding properties of the material.

For warming a house without special requirements, two stars are enough; for increased thermal protection and ease of installation, three stars are chosen.Four stars assigned to the product of the last generation with high thermal protection. In addition, each package has a label with accurate data regarding thickness, length, width, package volume and number of pieces.

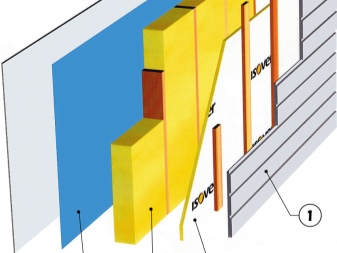

Mineral wool insulation is installed in the same way as any other heat insulating material. When weathe the walls inside the premises, the first thing to do is to make a crate of wooden or metal planks. They will later be attached drywall. Preliminary walls are grounded, and on those that border the street, a heat-reflecting coating is fixed.

When mounting the lathing it is necessary to observe the step corresponding to the width of the Isover, plates or mats. The next stage of the sheets of insulation are glued to the wall, if necessary, fixed water-repellent film and filled with horizontal strips.

Warming of the walls outside the building begins with the fact that a wooden frame is attached to the wall.

- It is usually made of 50 by 50 millimeter bars, which are attached vertically.

- Insulation can be installed in one or two layers. It is placed in the structure so that it fits snugly to the wall and frame without gaps and cracks.

- Next, over the top reattached bars, but horizontally.The distance between the horizontal bars should be the same as between the vertical.

- In the case of double-layer insulation, a second layer of thermal insulation is placed in the horizontal crate, overlapping the joints of the first one.

- To protect against moisture, a hydraulic windproof membrane is placed outside, a necessary ventilated gap is created, and after that you can proceed to the lining.

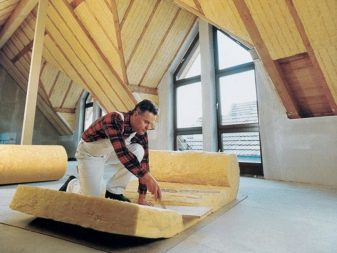

Warming of the roof begins with the fact that on the upper face of the rafters a hydro-windproof membrane stretches, which Isover also produces.

- It is fastened with a construction stapler, and the joints are glued with reinforced mounting tape.

- Further, it is recommended to start installation of the roof covering - a gap is formed on top of the membrane using a pressure bar, and then a coating is installed on the counter lattice of 50 by 50 millimeter bars.

- The next step is the installation of the heat insulator itself. With a standard distance between the rafters, the insulation will need to be cut into 2 halves and each set into a frame. Most often, one piece manages to insulate the entire length of the roof slope. If the distance between the rafters is non-standard, then the dimensions of the insulation boards are determined independently. We must not forget that their width should be at least 1-2 centimeters more.Thermal insulation should fill the entire space without gaps and cracks.

- Next, a vapor barrier is installed along the lower plane of the rafters, which will protect against moisture inside the room. Joints are glued with vapor barrier tape or reinforced construction tape. As always, the gap is left and the installation of the inner lining begins, which is attached to the crate with nails or screws.

Warming of floors by lag is chosen in two cases.: attic and ceiling above basements with no heating.

- First, lags are installed and roofing paper is laid to prevent rotting and destruction of the structure.

- Then the material of the insulator is installed inside. For cutting, a knife with a blade length of more than 15 centimeters is used. The roll is simply rolled out between the lag so as to close all the space, and no additional fixing action is required. During installation, moisture should be avoided.

- The next step is to install the vapor barrier membrane overlap, the joints, as usual, are glued with reinforced mounting tape or vapor barrier tape.A base is installed on top of the vapor barrier, which is attached to the logs with screws.

- Everything ends with a finishing finish: tiles, linoleum, laminate or carpet.

When carrying out activities for sound insulation of partitions the first step is to mark and collect guides and their further installation.

- At a separate partition it is necessary to veneer one side with plasterboard, and you can start creating sound insulation.

- Isover is mounted between the uprights of the metal frame without fasteners, tight to the structure and filling the entire space without gaps and spaces.

- Then the partition is sutured on the other side with drywall, and the seams are puttied using paper reinforcing tape.

Thermal insulation of baths and saunas It begins with the creation of a wooden frame of bars measuring 50 by 50 millimeters.

- Bars are mounted horizontally.

- Insulation is cut into two halves with a knife and installed in the frame, with the foil layer facing the inside of a warm room. As usual, the material is installed without gaps and cracks.

- The joints are well glued with foil tape, as well as the outer surface of the batten.All this will allow you to create a sealed vapor barrier.

- A crate is placed on top of the horizontal bars to create an air gap. It will speed up heating and increase the life of the sheathing.

- At the final stage, the inner lining is established.

One of the main mistakes when using Isover is the wrong choice of material width.

If the roll of insulation is free to lie between, for example, beams, the main goal will not be achieved. It will be quite expensive to cut it in several rows, and to leave it in such a state, despite the gaps and gaps, is completely meaningless. Therefore, it is extremely important to calculate all the required dimensions on the working surface, taking into account the length, depth and width of beams or crates.

In the case when the heater is in direct contact with the wires or the pipeline, it is necessary to check the tightness of communications. In terms of electricity, the situation is not very dangerous, but in the second case it is better to isolate communications with the help of a corrugated pipe.

In addition, all materials must be completely dry to the beginning of the process of warming.If the surface for which Isover is intended is wet, then you either have to wait for it to dry out, or dry the room with a hairdryer or a gun.

But the most terrible mistake, of course, will be the lack of waterproofing and vapor barrier. If you miss these moments, the material will be wasted, and the insulating effect has not been achieved.

How to calculate: instruction

It is very important to be able to correctly calculate the required thickness of insulation to create and maintain a comfortable temperature in the room. To determine it, it is necessary to reproduce the heat engineering algorithm, which exists in two versions: simplified - for private developers, and more complex - for other situations.

The most important value is heat transfer resistance. This parameter is denoted as R and is defined in m2 × C / W. The higher this value, the higher the thermal insulation of the structure. Experts have already calculated the recommended average values for different regions of the country, which differ in climatic features. During the construction and insulation of the house, it is necessary to take into account that the heat transfer resistance should be no less than the normalized one. All indicators are specified in SNiP.

During the construction and insulation of the house, it is necessary to take into account that the heat transfer resistance should be no less than the normalized one. All indicators are specified in SNiP.

There is also a formula that shows the relationship between the thermal conductivity of the material, the thickness of its layer and the emerging thermal resistance. It looks like this: R = h / λ. R is the heat transfer resistance, where h is the layer thickness, and λ is the thermal conductivity coefficient of the layer material. Thus, if you find out the thickness of the wall and the material from which it is made, you can calculate its thermal resistance.

In the case of multiple layers, the resulting numbers will have to be summarized. Then the obtained value is compared with the normalized by region. It turns out the difference that the insulation material will have to cover. Knowing the coefficient of thermal conductivity of the material chosen for insulation, it is possible to reveal the required thickness.

It is worth remembering that this algorithm does not need to take into account layers that are separated from the structure by a ventilated opening, for example, a certain type of facade or roof.

This happens because they do not affect the overall resistance to heat transfer.In this case, the value of this “excluded” layer is zero.

It must be remembered that the material in the roll is cut into two equal parts, usually 50 millimeters thick. Thus, identifying the required thickness of the squares of insulation, the product should be laid in 2-4 layers.

- To calculate the required number of standard packages. for roof insulation, it is necessary to multiply the area of heat-insulated roofing by the planned thickness of thermal insulation and divide by the volume of one package - 0.661 cubic meters.

- To calculate the number of packages to use for facade insulation for siding or wall paneling, the area of the walls is to be multiplied by the thickness of the insulation and divided by the packing volume, which can be 0.661 or 0.714 cubic meters.

- To identify the number of Isover packages required for floor insulation, the floor area is multiplied by the thickness of the insulation and is divided by the volume of one package - 0, 854 cubic meters.

Safety

When working with insulation, consisting of fiberglass, it is necessary to use protective glasses, gloves and gauze or respirator bandages.Clothing should be with long sleeves and trousers, in addition, do not forget about socks. It is better, of course, to insure and wear protective overalls. Otherwise, assemblers expect unpleasant consequences - itching and burning all over the body. By the way, this requirement applies to all types of work with any mineral wool.

To protect the inhabitants of the house from glass dust, between the insulation and the top layer, for example, clapboard, it is recommended to put a special film.

Even if the wood panel is damaged, particles of insulation can not enter the room. You can cut the material with a simple knife, but it should be sharp as sharp as possible, in extreme cases, you can use a sharp enough chisel.

Insulation must always be stored in a dry, closed place, and the packaging must be opened only at the installation site. The room should be well ventilated, and after completion of work, all waste should be collected and discarded. Also, after installation is completed, you must take a shower or at least wash your hands.

The pros and cons of Isover insulation are described in the next video.