Insulation Rockwool "Kaviti Butts": advantages and disadvantages

In addition to a full-fledged heating system, houses need additional insulation so that the walls do not freeze through. Modern construction market offers a wide range of products to ensure a more comfortable stay in a country house. One of these are insulation. The company Rockwool has long been producing mineral wool products for various purposes.

The most popular is the series of basalt plates "Kaviti Butts". It possesses not only thermal, but also protective properties, because at the expense of an additional layer, external walls receive additional strength. In this article we will talk about the pros and cons of products, consider their technical characteristics and applications.

Special features

"Kaviti Butts" is a mineral wool thermoplates. Such materials have enhanced characteristics and include a large number of useful properties. The developers of Rockwool have created a product that is unique in its functions, which has practically no analogues, since it has become the “last word” in the construction industry. All Rockwool thermoplates are made of high density basalt.

This material is optimal for wall insulation, as it has a low level of temperature melting.

The production of mineral wool slabs occurs by basalt melting in high-temperature furnaces, after which special resins are added to it, ensuring the screed of the raw materials and the formation of the final result, mineral wool. The resulting material has many advantages, the main of which is lightness. The plates have a very low weight, so they are easy to transport and stack. The moisture resistance and vapor permeability of the products are also very important advantages, especially for our latitudes.

Thanks to the rectangular shape of the slab, it is easy to install.The bio-resistance of thermoblocks prevents the appearance of mold and fungi, and also makes the material absolutely unsuitable for eating by rodents or insects. Basalt wool does not burn - this is a huge plus thanks to which the Kaviti Butts slabs are completely fireproof. In addition to the above advantages, you should also indicate the environmental friendliness of the material, which does not harm nature and human health.

Rockwool products have optimal technical characteristics due to which it is difficult to find any minus, however, some features of the plates still exist. One of the drawbacks of "Kaviti Butts" is a reduced density. In this case, it is necessary to take into account the absence of a strong load, so a high density of the product could greatly affect the cost, which is not so low. This is another drawback of the product, which fully pays for its quality.

Despite moisture resistance, thermoplates still accumulate a small amount of moisture due to the admission of steam. Accumulation occurs rather slowly, but this feature should also be taken into account.

Specifications

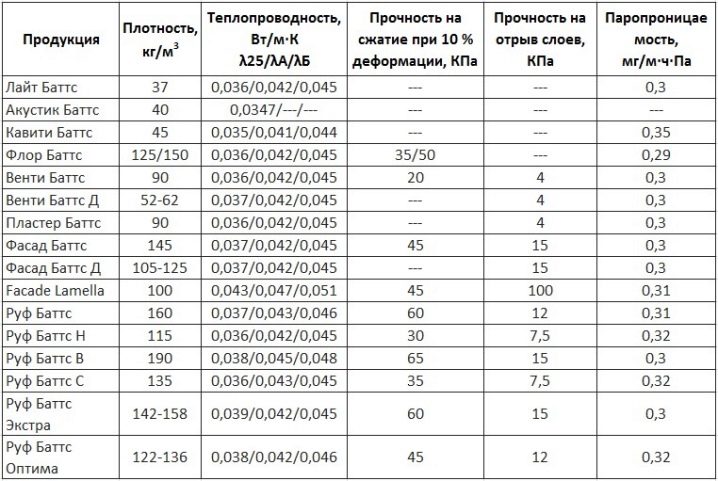

The development of the technical properties of "Kaviti Butts" occurred taking into account modern technologies and for certain purposes. Mineral wool boards have low thermal conductivity. In the Rockwool laboratories, the following experiment was carried out: a burner with an open flame was applied to the unit, only the place of contact of the fire with the surface warmed up a little, while the rest kept its standard temperature. The maximum index is 0.038 W / (m · K).

Caviti Butts are significantly lighter than their counterparts, however, low weight affects the density of the material. This indicator for thermoplates 50 mm thick is only 45 kg / m3. This indicator is not considered bad, but it is absolutely not suitable for the use of blocks in places other than walls or roofs.

You can not use "Kaviti Butts" in structures with a large load and voltage - this prohibition is indicated in the instructions.

The moisture-absorbability index of the heater is a maximum of 2% of the total volume of the plate. The manufacturer produces sixteen types of insulation with a standard length and a width of 100 * 60 centimeters, the difference is only in thickness, which varies from 5 to 20 centimeters.Depending on the thickness of the unit in the package can be from 2 to 10 panels. The vapor permeability of the material is 0.30 mg / (m · h · Pa), which is quite a bit, and is an excellent indicator for such a product.

Application area

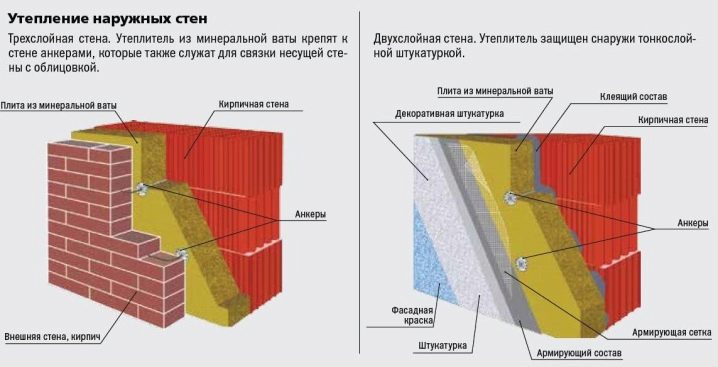

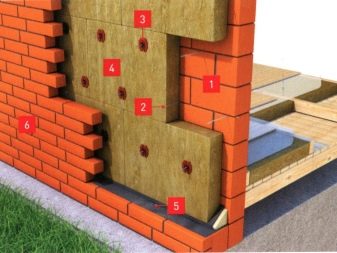

"Kaviti Butts" are intended for insulation of three-layer structures of brick or concrete. In this case, the first layer will be the carrier material, which is stronger than others and takes the main load. The second layer will be a rockwool insulation, which is laid on the surface and fixed. The final will be the facing layer that will cover the insulation. It can be made of facing bricks, gypsum-fiber slabs or moisture resistant panels.

As a rule, this design acts as an external frame of the building. These layers are not created for indoor use, as it is too expensive.

The outer wall with insulation "Kaviti Butts" will have increased strength, insulation and reliable protection from atmospheric agents and other influences.

Installation

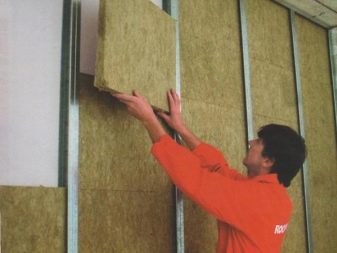

The process of laying mineral wool "Kaviti Butts" is quite simple - it can make even a novice in the repair business. Each package contains detailed instructions on the use of the product.However, in the case of self-doubt, it is better to turn to professionals.

The first step is to prepare the base for installation: the surface should be cleaned of dust and dirt, fill the existing cracks or irregularities and eliminate the protrusions. After thorough cleaning, there is a priming process for the final leveling of the wall.

Next, a special adhesive solution is applied to the thermopanel, after which the plate is fixed on the wall. During the preparation of the glue, you should also carefully study the instructions and not be mistaken in the ratio of mixture and water. It is recommended not to dilute all the packaging at once, as the mixture hardens quickly, it is better to prepare the solution in parts. Thus, you can not only save money, but also facilitate the installation process.

Some masters advise to additionally fix the blocks with dowels or self-tapping screws, however, this may violate the integrity of the material and reduce its technical properties.

After hardening of the glue, the insulation is closed with a third facing layer. At this installation process ends.

Reviews

The popularity of Rockwool products has provided a large number of reviews on the Internet.Customer opinions about the thermoplite “Kaviti Butts” are positive. Users are satisfied with the high quality of the product and its technical characteristics. A big plus is the low weight of the plates and their convenient rectangular shape. These qualities provide not only easy transportation of the material, but also ease of installation.

There is also a low thermal conductivity of the material, and high fire safety. They ensure the integrity of not only the whole structure, but also many values within it. Environmental friendliness and biostability of thermoplats are also considered important advantages, because due to these properties, the material does not harm the environment and the health of residents.

Among the shortcomings, buyers emit only the high price of the product, but it fully justifies the high-quality materials spent on production.

Learn more about the properties of Rockwool insulation, their advantages and disadvantages by watching the following video.