Warming of a wooden house inside: what and how to do it better?

Wooden house can rightly be considered the pride of the owners. Wood retains heat well and provides a favorable indoor microclimate, has an attractive design. However, in some cases, the insulating properties of the material is not enough, so the insulation of the house becomes the way out.

Features of the procedure

The most widespread outdoor insulation of the house. However, if it is impossible to perform it, it is necessary to resort to thermal insulation of the house, bathhouse or cottage from the inside.Immediately it should be noted that as a result of these manipulations, the effective area of the room in most cases decreases. An exception is made only for a log log house, which requires only inter-wool insulation.

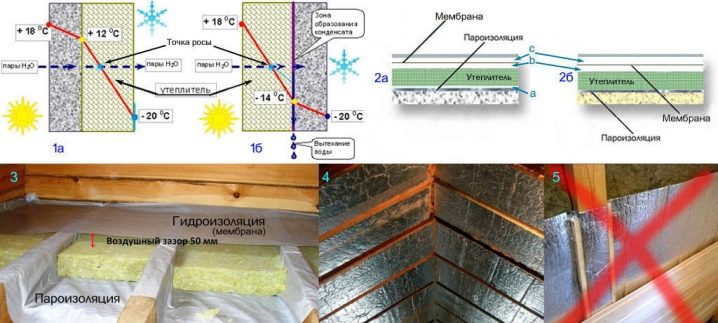

When the internal insulation of the house of any material always increases the humidity in the room. It is clear that this negatively affects the walls, especially wood. With improper thermal insulation in the first year of operation, the insulation becomes wet and loses its insulating properties, and wooden surfaces begin to rot and become covered with mold.

To avoid such phenomena allows the mandatory installation of vapor-permeable film and the creation of a powerful ventilation system.

When warming a wooden house from the inside, it should be remembered that, in terms of its efficiency, it cannot be compared with thermal insulation outside. This is due to the fact that the wall insulated from the inside does not accumulate heat, so heat losses amount to 8-15%. Moreover, cut off from a warm room with insulating material, such a surface freezes through faster.

Another important point is an integrated approach to isolation. Insulate not only the walls, but also the floor with the ceiling. If there is an unheated attic and basement in the house, then it is more rational to give primary and primary attention to these zones during insulation.

The colossal, up to 40%, losses of heat energy fall on windows and doors. It is important not only to use modern double-glazed windows and door leaves, but also to make sure that they are properly and tightly installed, to take care of the insulation and protection of slopes.

A common mistake when insulating a wooden house from the inside is to keep small gaps between the surfaces.usually between floor and walls, walls and partitions, walls and ceiling. Such gaps are called “cold bridges” because heat escapes through them and cold air penetrates.

Characteristics of thermal insulation materials

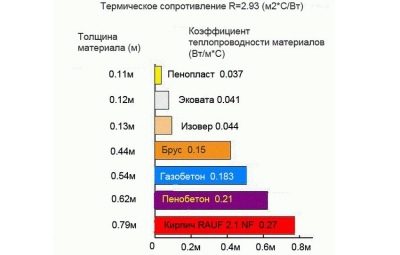

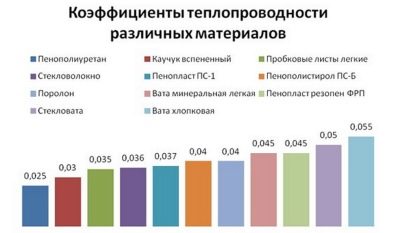

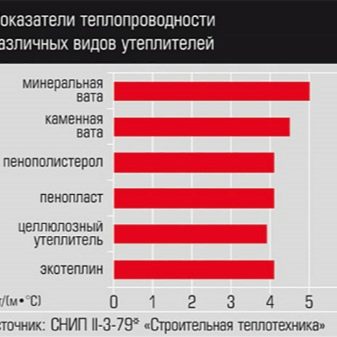

For any thermal insulation material, the most important characteristic is the thermal conductivity indicator. The lower it is, the less heat is borne by the house. It is measured in W / m × ° С, which means the amount of thermal energy leaving through a heater per m2.

When choosing a thermal insulation material for wooden surfaces, attention should be paid to vapor permeability indicators. The fact is that the tree is in itself a "breathing" material. It is able to take excess moisture from the air in the room, and in case of insufficient humidity - give it away.

It is easy to imagine that when using non-permeable insulation, moisture from wood will not find a way out and will remain between the insulating material and wood. This will be detrimental to both surfaces - wet insulation has a high thermal conductivity, and the tree begins to rot.

One more important criterion of a heat insulator is moisture resistance. It is usually achieved by applying water-repellent agents to the insulation and using a waterproofing film.

If we talk about mezhventsovym insulation, it is impossible to close the waterproofing film, so the resistance of the material, along with its thermal efficiency, comes to the fore when choosing a particular product. For indoor use, choose an environmentally friendly material. It is important that it belongs to the class of non-combustible or non-combustible, and also does not emit toxins when heated.

Bio resistance of the product directly affects its durability. If the insulation attracts insects or rodents, then in the course of their vital activity cracks and damage appear in it invariably, which causes the appearance of “cold bridges”.

Among other paramount characteristics - ease of installation, the variety of forms of performance and options for density, thickness, affordability.

The better to warm?

The most common option for insulation of a wooden house is insulation mineral wool. Usually, glass wool or stone wool is used to organize the insulation layer. The latter surpasses glass wool in technical characteristics, but most importantly, it is absolutely ecological.

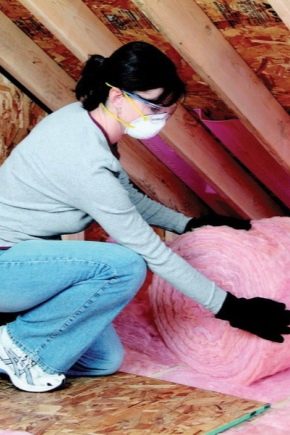

Glass wool during the operation produces toxic compounds, therefore it is not recommended for use indoors. In addition, it has the worst indicators of moisture resistance and fire resistance (although it has high fire resistance characteristics - the temperature of combustion is 400-500 degrees). Finally, it is prone to shrinkage and thickness reduction (and this leads to an increase in thermal conductivity), when laying requires the use of not only a respirator (like all mineral wool).insulation), but also workwear.

In this regard, the use of stone or basalt wool is more attractive. The basis of the material is recycled rock, which is subjected to high-temperature heating (over 1300 degrees). Then, thin fibers are extracted from the semi-liquid mass. In a chaotic order, they are formed into layers, after which they are pressed and subjected to short-term exposure to high temperatures.

The result is a material of different stiffness, produced in mats, rolls and tiles. Mats have the greatest strength, are suitable for heavily loaded structures, including floor insulation under the screed.

For wooden walls, in most cases, tiled basalt cotton wool is sufficient; it also fits between the wooden floor logs. It is convenient to use rolled products at isolation of equal horizontal surfaces, for example, a ceiling.

Insulating properties provide the location of the fibers, between which in large quantities accumulate air bubbles - the best heat insulator. The coefficient of thermal conductivity of the material, depending on the density and brand is 0.35-0.4 W / m × ° C.

In addition to high thermal insulation, the material shows good sound absorption performance. Sound insulation coefficient of impact noise reaches 38 dB, air - from 40 to 60 dB.

Unlike glass wool, basalt wool is characterized by low moisture absorption, which is on average 1%. In combination with high vapor permeability - 0.03 mg / (m × h × Pa), it allows to save wood from rotting and maintain a healthy atmosphere in the house. The melting point of stone wool is about 1000 degrees, so it is considered non-combustible material. In addition, due to the natural composition it is possible to achieve environmental safety of basalt insulation.

Ecowool is also suitable for wall insulation. 80% of the material is cellulose chips, treated with flame retardants and antiseptics, the rest is polymer resins, modifiers.

Ecowool refers to bulk materials, but it is also possible to spray it on the surface with the help of special equipment. Despite treatment with water repellents, the material requires a waterproofing layer. In terms of its thermal efficiency, it is inferior to stone wool.

Modern material for insulation - Penofol, also suitable for internal insulation. It is a roll of polyethylene foam (provides a heat-insulating effect) with a foiled layer applied on one side (reflects thermal energy inside the room). The presence of a metallized layer increases the strength and moisture resistance of the material, but makes it combustible (class G1).

The well-known expanded polystyrene, which has similar thermal conductivity, is not recommended for use inside a wooden house. The fact is that the material "does not breathe." A tree, as it is known, is characterized by the ability to take excess moisture from a room and give it away if necessary. In the presence of a polystyrene foam layer, the tree simply will not be able to get rid of excess moisture, which will lead to the onset of decay. In addition, polystyrene is characterized by toxicity and flammability, it often becomes home to rodents.

If, nevertheless, it is impossible to refuse its use, preference should be given not to foam plastic, but to extruded polystyrene foam. It is more environmentally friendly, has a higher fire safety.

Another durable and heat-efficient material - polyurethane foam (PUF), at first glance, is the best insulation. The low coefficient of thermal conductivity, as well as the characteristics of the application (it is sprayed onto the surface) allows not only to reduce heat loss, but also eliminates the risk of "cold bridges". However, polyurethane foam does not “breathe” and, if in the case of using polystyrene foam it is possible to organize a vapor barrier between a wooden surface and insulation, then during installation of PU foam, this layer cannot be created. After 5-7 years, the walls under the foam layer will start to rot, and to remove it - the process is quite laborious.

Special materials are used for inter-coat insulation. They may be of natural or synthetic origin.

Organic mezhventsovymi heaters, most often used for internal insulation, include the following types of materials:

Linen insulation

It has long been used for these purposes coarse, unsuitable for weaving linen fibers. Today, tape insulation is also made on a plant-based basis and is called flax felt or lnovatin.Differs in high density, vapor permeability (it is optimum for rooms with high humidity).

Jute

The insulant is based on recycled fibers of the bark of an exotic tree from the family of the same name. It is characterized by a high content of resins in the composition that provides strength and high antibacterial properties of jute. It protects not only the intervening space, but also the wooden surface itself. However, a large amount of resin leads to inelastic insulation. Over time, it becomes tougher and as if dries out, decreases in volume, which leads to the appearance of cracks. To level this disadvantage allows the combination of jute with lnovatin.

Felt

Natural wool material (sheep wool), thanks to which unsurpassed heat and sound insulation characteristics are achieved. It is processed by water repellents and compounds that prevent the appearance of insects and microscopic life forms in the insulation.

Sintepon, polytherm (synthetic polyester felt) and PSUL are popular materials of artificial origin. It is noteworthy that the name "polyterm" originally meant a certain material of the Finnish manufacturer. However, over time, the term has become a household name. Today, they are designated as a specific manufacturer, and a type of polyester insulation.

Under the acronym PSUL hides the following name - pre-compressed insulation. Its main ability is the ability to contract and expand in accordance with linear changes in the size of wood without losing its technical characteristics. In terms of thermal conductivity and moisture resistance, it exceeds the similar values of natural insulation. At the same time, it is characterized by vapor permeability, biostability, environmental safety and fire resistance.

When heat insulation mezhventsovyh seams should abandon the use of such heaters as tow and mineral watts because of their lower moisture resistance.

Manufacturers Overview

Choosing insulation for a wooden house, it is worth preferring well-known, well-established brands.

- Leading position among manufacturers is the company Rockwool (Danish brand, which is also produced in 4 cities in Russia). The range delights diversity. For each section of the house has developed its own line of products. So, for the walls the mineral wool “Butts Light” and “Scandic” will be optimal. There are innovative mats for walls of different stiffness within the same mat, roll and slab counterparts. The disadvantage is the high cost (on average 1500 - 6500 rubles / m2).

- In terms of quality, products from Germany are not inferior to tile and roll mineral wool of trade marks. Knauf and Ursa. To insulate the room from the inside, it is enough to choose materials with a density of 10-25 kg / m3. The price is between 1200 and 3000 rub / m2.

- Leading positions are occupied by French mineral wool insulation in plates, mats and rolls from the brand. Isover. In the collections you can find both lightweight products (density of 10-20 kg / m3) and hard mats for frame houses (density of 150-190 kg / m3). The cost is quite high - from 2000 to 4 000 rubles / m2.

- The mineral wool produced in Russia is mostly not inferior to its Western counterparts in the characteristics of heat efficiency, vapor permeability and fire resistance. However, it has a more affordable price.User feedback allows companies such as TechnoNicol, Izovol.

All manufacturers mentioned above produce a kind of thermal insulation wool with improved sound insulation performance.

- Among the best manufacturers of ecowool worth noting firms Isofloc (Germany), Ekovilla and Termex (Finland)as well as domestic companies Equator, Ekovata Extra and Nanovata.

- Finnish mezhventsovy heater "Politerm" It is considered to be one of the most optimal for operation in domestic conditions. In addition to improved insulating qualities, it is characterized by the presence of special shaped elements for the design of joints, corners, transitions in the house.

- A similar mezhventsovy heat-insulating material based on polyester is produced by the Russian brand. "Avaterm". According to the manufacturer, thanks to the highest performance characteristics, the material can last up to 100 years. Popular brands of sealants are Weatherall and Neomid Warm Seam.

How to choose?

When choosing a material, it is important that its density matches what is required in a particular area of the house.The density in some cases (absolutely in all mineral wool products) depends on thermal conductivity, stiffness, weight and bearing capacity of the material.

Typically, manufacturers indicate not only the density, but also the recommended use of the material.

Pay attention to the storage conditions of products. Mineral cotton insulation should be stored in a sealed original packaging, even a slight soaking of products is unacceptable. Expanded polystyrene is afraid of sunlight, under their influence, it begins to break down.

Types of technology

Depending on the type of materials used, as well as the installation methods used, the following technologies of thermal insulation of a wooden house are distinguished:

Warm seam

It is used for mezhventsovogo insulation of log houses, for sealing joints between the masonry foundation and walls. Suitable for objects that do not provide additional wall decoration from the inside. For insulation, special mezhventsovye insulators, as well as silicone sealants. The advantage of this method is less labor-intensive and costly process, the ability to preserve the natural beauty and the vapor permeability of wooden coatings.

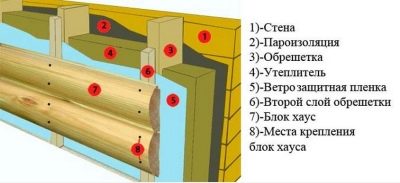

Insulation on the crate

It is provided in the presence of interior walls, as well as insufficient thermal efficiency mezhventsovogo insulation. It requires mandatory vapor barrier and walls and additional ventilation of the house, fixing the frame, fixing insulation, solid skin of the frame with plasterboard and fixing the finishing material on it. Such insulation is effective, and to avoid condensation, there is a gap between the insulation and the skin for air circulation.

How to do it yourself?

- Regardless of the technology used, in the first place should prepare the walls. If you decide to do the work with your own hands, then you should start by cleaning them from dust, dirt, and the old coating. When cracks are detected, they are treated with a sealant, all irregularities are cleaned. Before insulation should also remove all communications from the walls, check the wiring. The preparatory stage is completed by applying an antiseptic primer and flame retardants to the surface.

- Installation of vapor barrier film. It is attached to the entire surface with a gap of 10 cm and fixed with construction tape.If financial possibilities allow, instead of a vapor barrier film, it is better to use a more efficient vapor barrier membrane. Once again we recall that the vapor barrier is only one of the components of maintaining optimal humidity and a favorable microclimate in a wooden house. The second mandatory "component" is the ventilation system.

- Creation of wooden crates, which is fixed to the walls of the house through the brackets. The crate is assembled from wooden logs, which are pre-treated with flame retardants and antibacterial compounds. The pitch of the sheathing corresponds to the width of the insulation, and when using mineral wool products it can even be 1-2 cm narrower. The most common, as already noted, insulation for wooden walls is mineral wool. Its layers are placed between the elements of the batten and secured with dowels.

- Chipboard installation or drywall sheets as a facing layer. There is a small gap between the sheets of drywall and the insulation layer, which provides better thermal insulation and allows the insulation to be ventilated.If ecowool is used as a heat insulator, then plasterboard sheets are attached to the crate immediately, and ecowool is poured into the resulting gap. Sheets of gypsum plasterboard are puttied in several layers with preliminary treatment of each layer with fine sandpaper. After applying the final layer of putty, you can begin to fix the wall decorative coating - wallpapering, painting, etc.

Today, you can find mineral wool plates with different density in thickness.

The part of the slab that is attached to the wall has a looser structure, the outer surface is more dense and stiff. Such materials are glued to the wall using special mixtures. Due to the high rigidity of the outer side of the heater, it is possible to do without mounting the batten. The material is covered with glue, reinforcing fiberglass is mounted on it, on top of which plaster is applied in several layers, and paint or decorative plaster is applied on it.

A little different look lining the walls of logs or timber.

- Immediately after the erection of the building, primary insulation of the intervening gaps is produced, which is also called caulking.To do this, in the gaps using a caulk or a spatula, a twisted mezhventsovy insulation is inserted. When using synthetic materials, a layer of sealant is applied on top of them.

- After a year (it was after so much time, the house gives the maximum shrinkage) they re-caulk. First of all, the condition of the wooden surface itself is assessed. At detection of chips and cracks they are filled with the same elastic sealant. Next, check the quality of insulation mezhventsovyh seams. It is better if this is done not only “by eye”, but also with the use of a thermal imager.

- If they find points of heat loss, they re-caulk. If additional warming of log walls is not provided, then the joints are re-treated with sealant, now for decorative purposes. Modern compositions are characterized by a wealth of colors, so the user can choose a mix to match the logs. Another option to close the joints is the use of jute braid, which has an attractive soft golden hue and looks harmonious with most types of wood.

- If further thermal insulation of the walls is expected, then the steps described above (primer, creation of a vapor barrier, installation of the frame and fixation of the insulation, fixing the plasterboard, finishing) are carried out. Thermal insulation of the ceiling also implies the creation of a batten under which a waterproofing coating is laid, for example, glassine. Further, with the help of screws and special glue, the insulation is fixed to the ceiling. The next step is plasterboard ceiling and finishing cladding.

In the presence of the second floor insulated ceiling. For interfloor overlap materials of increased rigidity are required.

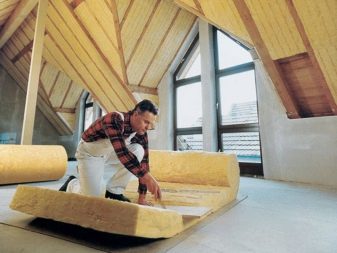

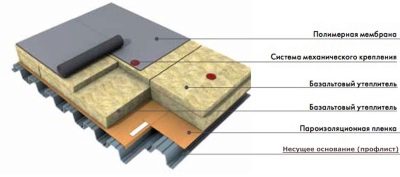

If in the house there is a loft of an unexploited type, then bulk materials can be used for its insulation (expanded clay, ecowool). For heated attics and mansards special basalt heaters of increased rigidity are produced. A heater of maximum stiffness (from 150 kg / m3) is required for a flat roof.

When warming the floor first of all, it should be leveled, overlapped and with a small (up to 10 cm) “crawling” on the walls of the waterproofing membrane. After that, lay wooden logs in increments of no more than 50 cm.Mineral wool (or polystyrene foam) is laid between the lags. A layer of insulation is closed with a PVC membrane, on top of which the flooring is mounted (usually sheets of chipboard or plywood).

Useful tips from the pros

Experts recommend to carefully calculate the thickness of the material, since the indicators of its thermal efficiency depend on it. With insufficient insulation layer in the house will not be able to reach the optimum temperature. An excessively thick layer is not only unjustified financial expenses, but also an additional load on the supporting structures, as well as a change in the location of the “dew point”.

The latter term refers to the boundary where moisture escapes from a room into vapor in a liquid. Ideally, this should occur outside the heater, however, if its thickness is incorrectly calculated and the dew point technology is violated, the “dew point” may be inside the heater.

Wrong is the insulation of a wooden house inside and out. The wood surface is between 2 vapor barrier layers, which violates the natural ventilation of the material and leads to the beginning of putrefactive processes.

Professionals strongly recommend using outdoor insulation as a more efficient and proper for the operation of a wooden house. Warming from the inside - an extreme measure. Insulation should be carried out in the warm season, in dry weather, because during this period the walls are as dry as possible. If you plan to warm the newly built home, you should wait a year. This is due to the fact that wooden objects shrink.

When installing the batten, make sure that its pitch corresponds to the dimensions of not only the insulation, but also the sheets of drywall. Otherwise, you will have to fill additional rails - an extra load on the frame and an increase in labor intensity. The best option is to select sheets of insulation and drywall of similar dimensions.

Despite the cheapness of the foam, as well as its low heat transfer, discard the insulation of wooden walls with this material.

- It has low vapor permeability, which will lead to decay of the walls, increased humidity in the house, the appearance of condensation on the walls and mold on the finishing material.

- It allocates hazardous to the health of styrene, in connection with which in some European countries there is a ban on the use of polystyrene foamwith interior decoration.

- It is a combustible material that releases toxins when the temperature rises. When using foam in a wooden structure, you can create a real fire trap.

The sealant used for inter-coat insulation should be flexible and able to shrink and expand in the process of shrinkage and thermal expansion of wood. For use inside the house will be optimal composition of acrylic base. If you need a stronger sealant, then fit acrylic with the addition of polyurethane foam. An important point - such a sealant can not act as an independent insulation.

When weaving intervening gaps, it is important to conduct work around the entire perimeter of the building. That is, first along the entire perimeter, the first row of gaps is insulated, then you can proceed to the second. If you first insulate one wall, and then the second, do not avoid warping the house.

About how to insulate a wooden house from the inside with your own hands, see the following video.