Shiber for ventilation: purpose, classification and design

Shiber is an indispensable element of many engineering networks and is widely used in the construction of ventilation. Despite the simplicity of the design, the role of gates in exhaust installations is difficult to overestimate.

Purpose and principle of action

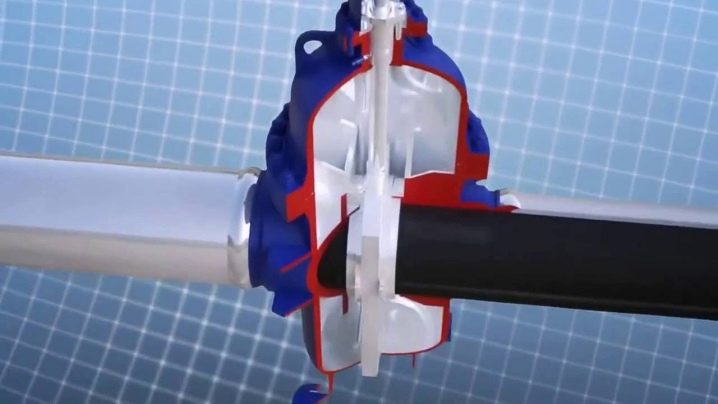

The gate for ventilation is a valve capable of completely or partially blocking the movement of air flow in the duct. The literal translation from German of the word schieber is a catch. The name fully discloses the functional purpose of the device. The device is used in ventilation networks to increase the productivity of their work by regulating the intensity of the passage of air masses. The gate is sometimes called the “throttle”, but this term does not refer to all devices, but only to those equipped with a rotary mechanism of constipation.

The principle of operation of the gate in exactly the same principle as the furnace damper used to regulate the thrust in the chimney pipe. So, when fuel is ignited, the flap is opened, thereby providing a powerful movement of air flow from the blower to the pipe. In the process of the active phase of combustion, they slightly overlap, preventing instantaneous burning of fuel, and after the last embers are exhausted, the valve is closed almost completely, leaving only a small gap.

Thus, the stove valve plays the role of a regulator of thrust, allows you to control the speed and intensity of the passage of air masses through the chimney. The same principle works vent gate. He then increases, then limits the current of air jets. In addition, the valve aligns the resistance of air flow inside the duct, regulates their passage from its main part to the branches. Gate valves can be mounted on air ducts of any material, including plastic.

Specifications

The design of the gates depends entirely on the place of their installation, the temperature of the air masses and the shape of the ducts.All valves have an absolutely smooth surface, which is dictated by work in conditions of temperature drops and the need for regular cleaning. In addition, the valve must be perforated or be equipped with a slot. This will not completely block the flow of fresh air into the room and will ensure the preservation of a favorable microclimate.

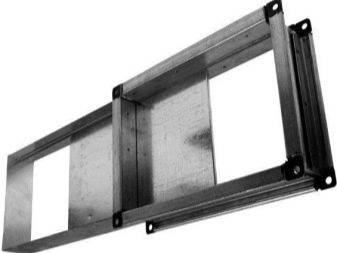

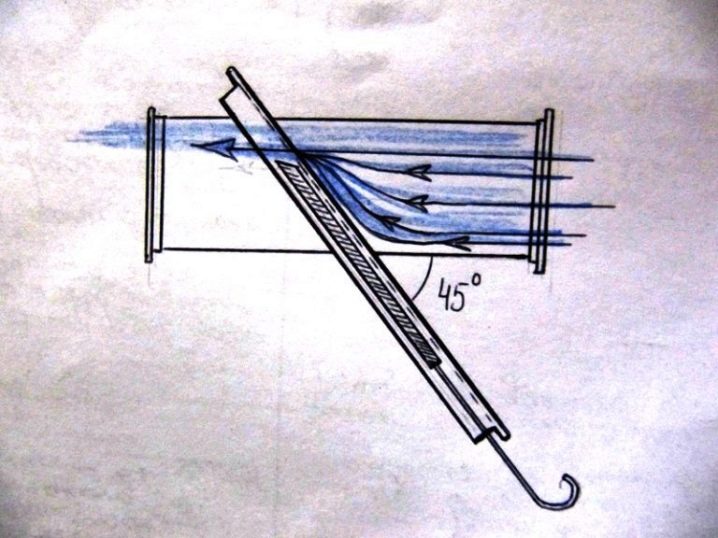

Shibera are retractable and rotary. The first are used in ventilation systems with forced circulation of air flow, and are straight valves made of steel. They are set perpendicular to the direction of flow. This design allows you to control the amount of air flow and, if necessary, change it.

Rotary models, called throttles, can be installed on a ventilation with natural thrust. Models are presented in the form of a plate fixed on the axis, and are driven by a rotary knob. The handle, in turn, is fixed on the plate by means of a bolt and lamb nut, and opens the valve by 10 degrees with each turn. All valve parts are made of galvanized steel and, if necessary, are additionally painted.

In the supply and exhaust systems, the installation of the gates is made in the duct gap in front of the fan. Such an arrangement of the flap prevents the fan motor from overheating: when the fan starts, the flap is closed, and after the number of revolutions reaches the operating parameters, it is opened. In this case, the gate acts as a start valve, which increases the efficiency of the fan and prolongs its service life.

Species

In addition to constructive differences, gates differ from each other in a number of ways.

The form

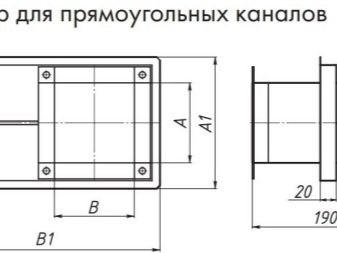

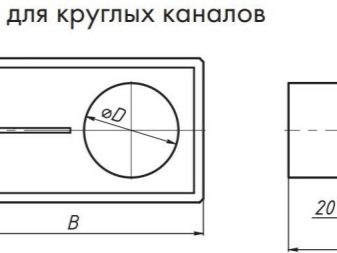

The configuration of the dampers depends entirely on the shape of the duct section and is round and rectangular. The air ducts of round section have the best throughput, however, in some cases, the installation of square and rectangular models is practiced as forced measures. This usually happens if you want to hide the duct pipe behind an imaginary wall or ceiling with a minimum of free space. The operation of electric heaters with a square cross section is also one of the reasons for installing rectangular pipes.Whatever the shape of the duct, the gate must repeat it exactly.

Control method

On this basis, the gate valve is divided into several types. There are models with manual, automatic, pneumatic and hydraulic control methods. The choice depends on the technical conditions of installation of the ventilation system and the personal preferences of the host.

Manufacturing material

For the manufacture of sliding and throttle valves using high-alloy, galvanized or chrome-plated steel. Due to the operational characteristics of the material, metal models are characterized by high strength, long service life and resistance to aggressive media. The devices are well tolerated by the effects of temperature and steam, so they can be installed in the ventilation system of any type of buildings without restriction.

Mounting method

Installation of gates can be done in two ways: flanged and bell-shaped. The first involves the use of mounting flanges, and when using the second valve is inserted into the gap duct using sockets.

Installation details

With a socket-mounted pipe-to-pipe installation, the damper is mounted at the ends of the duct and does not requireuse of fasteners. Docking seams are thoroughly coated with silicone sealant. If abstraction of hot or saturated air is intended, heat-resistant and water-resistant compounds should be used. It is allowed to use the ventilation only after the material has completely hardened. In addition to the sealant, the use of butyl rubber tape capable of carrying temperatures of 100 degrees or more gives good results. A shrinkable cuff containing a hot-melt adhesive layer has a slightly lower heat-resistant capacity. This seal is able to work at high humidity and temperatures up to 80 degrees.

The flange method is used when installing gates on air ducts of rectangular section and is regulated by SNiP 3.05.0185.

- The main condition for the installation is the use of fasteners. They are made of high strength materials and are able to withstand the aggressive effects of the external environment.

- The fixing of the flanges must be done with four or more bolts, all of which must be located on the same side of the installed flange.

- When placing the device in horizontal planes, the heads of the mounting bolts should be on top.

- After installation, check the valve stroke. The gate should open and close freely, without dangling and not getting stuck.

- The flange joint requires compulsory sealing measures, for which porous foam rubber or heat shrink mastic from bitumen and polymers can be used.

- At installation of models with the electric drive it is necessary to take care of the availability of a power source with a voltage of 220 volts near the flap.

Thanks to the simplicity of design and ease of installation, sliding products can be designed independently. However, the use of self-made models is permissible only when they are installed in the ventilation system. When planning the installation of gate valves in the smoke exhaust system of a wood stove or fireplace, it is strongly recommended to use factory-made models. This is due to the requirements of fire safety equipment, the rigor of the execution of which is strictly required.

Gate valve is an important part of the ventilation system.With its help, the intensity of the air flow entering the room is adjusted; the penetration of cold air in the winter time is not allowed.

The video below gives a detailed answer to the question of whether a gate for the chimney is needed.