Features and purpose of ventilation control cabinets

The ventilation control cabinet is an important component of large ventilation systems and allows you to combine a wide variety of technical devices into a single control and monitoring unit.

What is and what is it for?

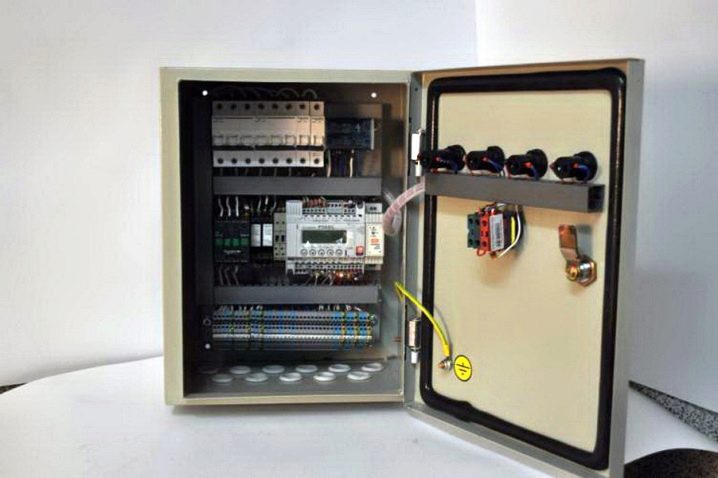

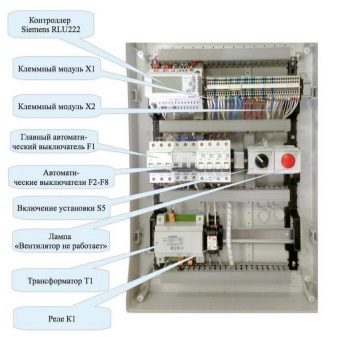

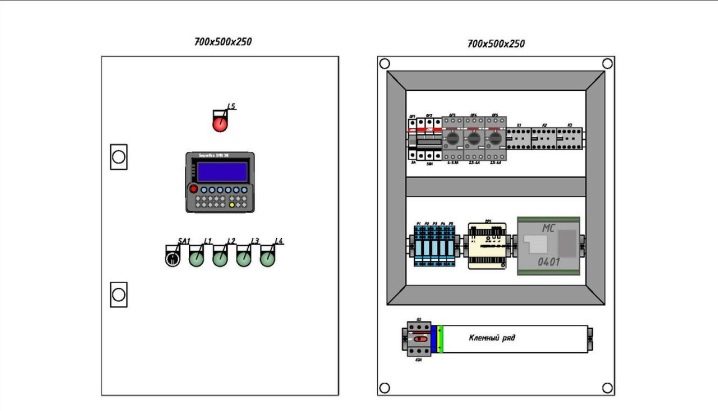

The control cabinet is a shield (SCHUV) or stand with located on it measuring devices, control sensors, indicators of sound and light, as well as mnemonic diagrams and switches. All controls are clearly visible and accessible to commands. The method of controlling ventilation using cabinets can be either manual or automated.The latter involves the use of microcontrollers capable of programming the operation of the system, and does not require the constant presence of a person.

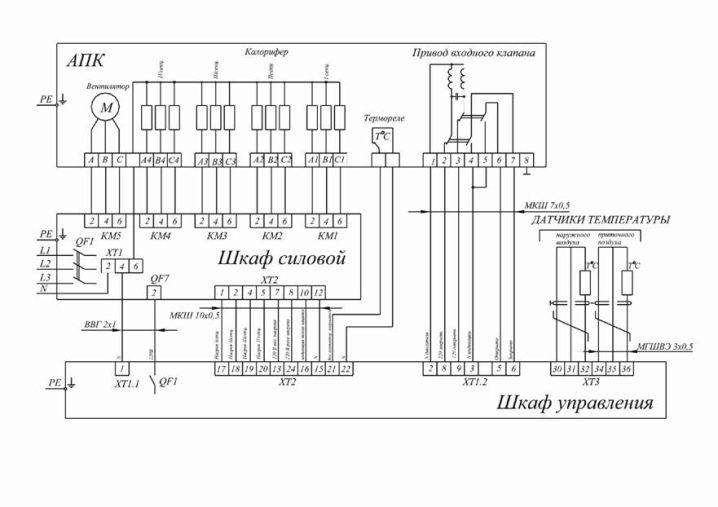

The main functional responsibilities of the control cabinets are adjustment of the speed of the supply fan, control of the electric drive of the valve, control of temperature parameters and on / off of the ventilation unit and display. In addition, the shield is able to control the operation of air valves, slow down air circulation, protect heat exchangers from freezing, prevent overheating of the windings of the engine and electric heater, and also signal contamination of the filtration system and abnormal situations. Installing the shield allows you to maintain the required temperature in the room and monitor the humidity indicators. The scope of application of ventilation control cabinets is quite wide and affects almost all types of ventilation and air conditioning systems.

The consoles are used to monitor water and electric heating systems., for devices with heat recovery, installations operating on the principle of heat flow recirculation, as well as exhaust, supply and retaining ventilation systems.For arranging domestic household ventilation systems, installing a control cabinet is often impractical. However, in large-scale large-scale networks with a large number of places inaccessible for continuous monitoring (attics, mines and basements), the installation of a control panel is simply necessary.

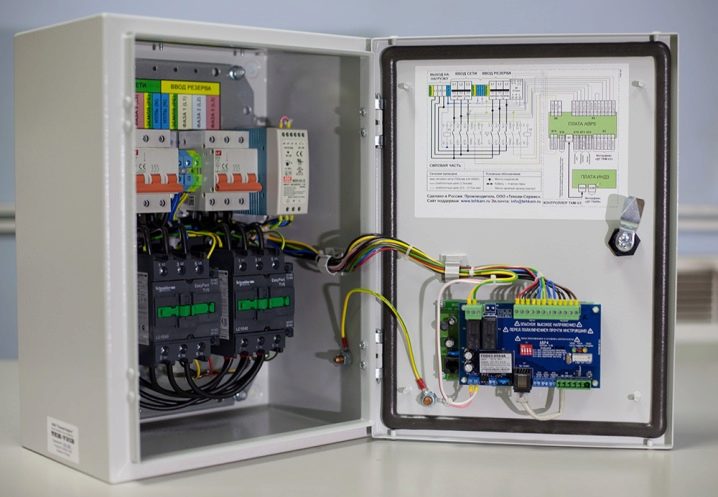

To destination control cabinets are general exchange and fire, and can also combine the one and the other functions. The instrument case is made of plastic or metal, and plastic models, as a rule, are equipped with a cover or doors, and metal ones are made in the form of a console or shield. In most cases, all cabinets meet the high protection class IP 31, but if the panel is used in extreme conditions of temperature or humidity, the protection class is increased to IP 45. The devices can be installed on the floor or suspended on the wall, unite all devices of the building or serve a specific section or floor. The choice of location depends on the configuration of the device and the dimensions of the installation.

Accessories

The fan control cabinet is equipped with a power supply, controllers, converters and a large number of on / off switches.The switches, in turn, are connected to electric air heaters, heat recovery devices, fans, water heaters and refrigeration units. An obligatory element of the shield is the manual control unit, which assumes the functions of regulation and control in the event of failure or failure of automation. In addition, all cabinets are equipped with sensors for emergency alarm, triggered in case of emergency or pre-emergency situation.

A special role in monitoring the operation of ventilation systems is played by sensors, which are a kind of receptors, and collect information about the health of each node. With their help, you can get a clear picture of air pollution, their temperature and humidity, as well as the speed of movement of air masses and the frequency of rotation of the fan blades. Temperature sensors are available in both digital and analog versions, and when changing the temperature conditions inside the system, they contribute to switching the entire installation to another mode. The same principle works and humidity sensors. The information received by the sensors goes to the automatic regulators, which, in turn, perform the adjustment of the work of the key nodes of the ventilation systems.

According to the location of the sensors are divided into external and internal. The first ones are often called atmospheric and are installed outside the buildings. Internal, in turn, are divided into channel and surface models. Duct mounted inside the duct on the walls or across the movement of air masses. Surface are placed on the surface of the nodes and carry out the removal of parameters from these devices.

An equally important element of control cabinets are controllers. Devices accept information coming from the sensors and process it automatically. After processing the parameters, the controllers send a signal to the main units of the ventilation units, such as fans, heaters, refrigeration units, after which they change their operating mode. Functionally, the controller can either maintain several devices, or interact with only one of them. Universal models are often equipped with microprocessors, which makes them less cumbersome and makes it easy to place them in a small cabinet or on a stand.

Another element of the shield configuration is the fan blade frequency converters.Thanks to these devices, it is possible to regulate the number of revolutions of the engine, thus significantly reducing the amount of electricity consumed by the installation. In addition to cost savings, this leads to a significant reduction in wear of fan parts and extends the overall life of the ventilation unit.

Device layout

Connection of control cabinets is carried out according to the standard scheme and is regulated by GOST R51321-1. Cabinets, stands and shields are installed in corridors, shield rooms or utility rooms. In the presence of technical conditions, the ventilation and fire control units are located in the same cabinet, which is placed in the control room. This will provide quick access to the emergency and working ventilation control panels and will allow you to quickly respond to system problems.

The premises in which the installation of shields, special demands on the level of humidity and temperature. Devices should be protected from direct UV rays, water droplets and dust. Magnetic oscillations and radio interference can also negatively affect the correct operation of devices, so their effect on devices should be limited.The temperature range at which the operation of control cabinets is allowed is from -10 to +55 degrees. Installation of the device requires mandatory grounding, and the frequency of the mains current should not exceed 50 Hz. The power supply used by the mains of 220 and 380 V.

The main requirements of the layout is the location of all control devices on one stand and in the same plane. The most important components responsible for the safety of the device must be equipped with indicator lights and preferably connected to a personal computer. In addition, devices responsible for the correct operation of the main nodes must be equipped with two types of control: manual and automatic. The most convenient for operation are cabinets, equipped with a remote control, allowing a person who does not have much experience in the management of ventilation, to monitor its work. In addition, the device wiring diagram should be simple and extremely accessible. This will help in the event of an emergency to turn off the installation yourself, without waiting for the arrival of repair services.

Installation

Installation of control cabinets for ventilation should only be carried out by an electrical installation wizard who has the appropriate approval and is familiar with the device of instrumentation and automation. Make a shield or remote control with their own hands is unlikely to succeed. Installations get in finished form and establish according to fire-prevention specifications. The cabinet is placed in a vertical position on the floor or suspended from the wall so that the person can easily access the sensors and switches. The height of the shield or stand must be at least one meter.

The kit of parts for the ventilation cabinet must have accompanying documentation with a detailed assembly scheme, any deviation from which will lead to serious troubles. The installation process itself takes not much time. All elements are connected in the necessary sequence, connecting the wires to the terminals and placing them between the lines. An important condition for proper connection is careful handling of wires, which are strictly prohibited to entangle and bend. Usually neat bundles are formed from wires, then they are tied up and brought out.After that, an experienced electrician connects the wires of the sensors, controllers and switches with their devices and makes a test run of the system.

Professional Tips

The efficiency and reliability of the further work of the ventilation unit or of the exhaust depends largely on the correctness of the choice of the control cabinet. Therefore, it is better to entrust the acquisition of such an important and technically complex unit to professionals. Before purchasing the cabinet, the master will carry out a full monitoring of all units of the ventilation system and determine the filling of the cabinet. After choosing a complete set, the specialist will test the installation and determine the maximum possible load on a particular device and on the network as a whole. Based on the received data, the master will select the optimal connection scheme, determine the operation mode of all devices in order to increase their efficiency, and only after that will point to the necessary equipment.

When choosing equipment independently, it is necessary to focus on the strength of the current in the circuit, the power of the units and the size of the cross section of the wires. This is due to the factthat in case of mismatch of the wire and current there is a strong overheating of the terminals and contacts, which can lead to breakage and even ignition of the equipment. When purchasing and connecting the cabinet yourself, you need to remember that for every square millimeter of copper wire there should be no more than 10 amperes, and the closure of the terminals, one of which is made of copper, and the second of aluminum is unacceptable. This may cause a galvanic effect and weaken the contact.

Control cabinets for ventilation are an integral part of large ventilation systems. They allow you to concentrate the management of different network devices in one place, make adjustment and control over the installation more efficient.

To learn how to install a simple ventilation control cabinet, see the following video.