Features and ventilation device in a wooden house

Any building is exposed to physical and weather factors. Cold, heat, temperature drops - all this negatively affects the state of any building. This has a particularly negative effect on timber houses, as it responds more strongly to the categories of impact mentioned. For this reason, such buildings really need ventilation.

Do I need air circulation?

Many experts argue that buildings made of wood are "breathing", they do not need special creation of ventilation systems. In their opinion, it is sufficient that air enters the building through the windows, as well as the gaps between the wooden elements. Previously, perhaps it could be.

But today, wooden buildings are built in such a way that natural ventilation in the house of wood is simply absent. Builders are trying to make such a house as efficiently as possible and to prevent the presence of cracks and drafts in order to preserve heat as much as possible. Installation of windows and doors is also carried out as tightly as possible, and the joints and gaps are treated with special substances. That is, in such a house there is simply no possibility for fresh air masses to enter the premises. Another problem appears - exhaust air must also go somewhere. At least, already for these reasons, there should be a ventilation mechanism in a private house.

But that's not all, because There are other reasons.

- Wood absorbs moisture very easily, which can cause its destruction and decay. Due to humidity, fungus and mold can occur.

- Despite the fact that wood is better able to pass air than concrete, without special formation of the ventilation mechanism there is no effect from this.

- Maintain temperature balance. It is thanks to the ventilation that it is easy to use the used air masses to heat the room.

- Water, heat and carbon dioxide cannot be removed by the tree, which means that it is impossible to do without the circulating air system.

In general, as you can see, the need for air circulation in a wooden house is very, very high.

Device and principle of operation

To be nice to be in such a building, it is necessary not only the presence of clean air, it must also have the appropriate temperature. And the air should arrive at a certain speed. And the lower this indicator is, the more comfortable it is to be inside the building. Air exchange with the use of a mechanical air-exhaust ventilation system will be significantly more than in the case when it comes to the natural counterpart. For a system where there is a hood, this figure varies in the range of 3-5 cubic meters per hour, and in the version with the natural one it does not exceed one cubic meter during the same time.

For this reason, natural ventilation provides conditions somewhat more comfortable. But there are cases when you cannot do without a mechanical type system. The lower will be the speed of air transportation in the pipeline, the higher its cross section will be.For the same volume of the pass, if a natural ventilation is used, a channel will be needed that has a larger cross section than with the version with mechanical ventilation.

For exhaust, the capacity of which passes three hundred cubic meters per hour, a channel with a diameter of 35 centimeters will be necessary for natural transportation. For a mechanical type hood, a channel with a diameter of only 20 centimeters will be needed. Not always a large channel can be placed in the wall. But its installation along the wall or under the ceiling, from an aesthetic point of view, may not be the most successful solution.

Types of systems

How exactly will the air exchange in a particular wooden house, you should think before construction begins and even before the start of the design phase. Ventilation in such a house is usually organized by a natural method. The passive option involves the flow of air through a number of channels:

- special airways that are made on the ground floor;

- window gaps in wooden windows, although this option is no longer relevant today;

- microcirculation mechanism in new plastic windows;

- open windows and vents in the summer;

- inlet valves, which are quite interesting modern solutions.

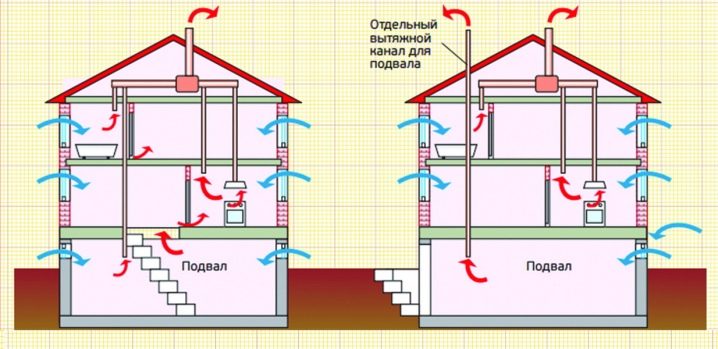

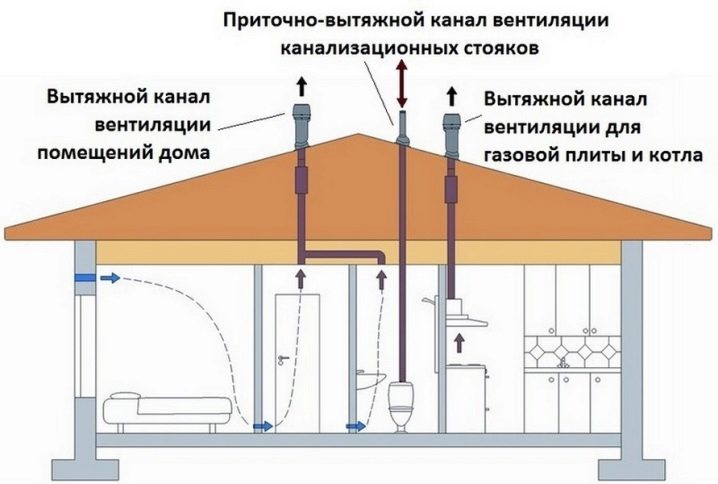

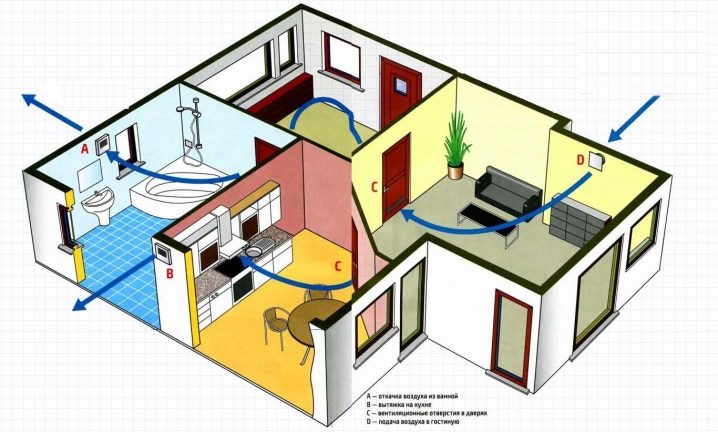

The first type of ventilation, which should pay attention - passive. Passive ventilation provides for the release of used air through the channels of the vertical type beyond the roof. A classic is the creation of exhaust channels from the toilet and kitchen. In recent years, the best solution is to place vertical extracts of mines separately for residential premises, kitchens and toilets. And if there is a reverse thrust, then this avoids the danger of mixing smells.

Circulating air mass between the rooms in this case will be provided with the help of a gap from the floor at the bottom of the door leaf. The entrance to the exhaust shaft will be located at the top of the wall. For the laying of the mine itself, it is best to use pipes made of metal with a minimum number of bends or plastic having a smooth surface. The advantages of such a system include:

- low cost of arrangement;

- durability;

- ease of installation;

- reliability;

- low cost of components, which includes ventilation pipes, inlet valves,ventilation grilles;

- no need to spend money on electricity;

- ease of use;

- ease of cleaning ducts.

But a wooden house, ventilation of which is made by passive technology, has serious drawbacks:

- the inability to precisely adjust the characteristics of temperature and humidity;

- the efficiency of air exchange during the summer period is significantly reduced.

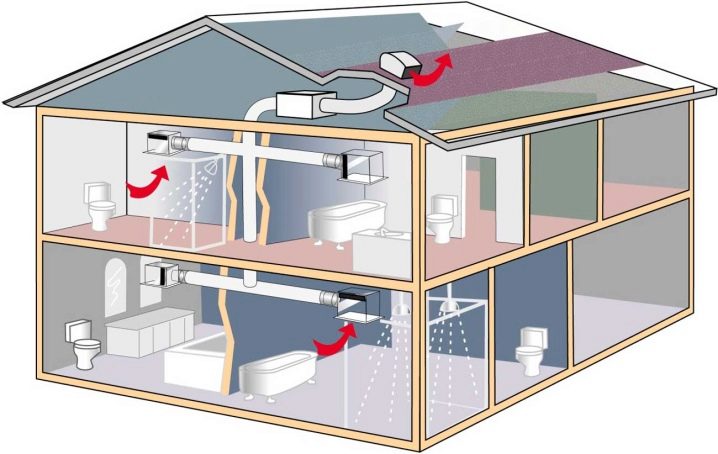

Another option is active ventilation. This solution has a high efficiency of air exchange, the ability to accurately determine temperature values and humidity. In this case, the inlet equipment is used with a fan, humidification mechanisms, cleaning filters and noise absorbers. If such a system is installed in a house with an attic floor, you can increase its efficiency by placing an exhaust type fan. Using the system allows you to provide the best conditions in any weather and make your stay in the room comfortable. But such a system also has significant drawbacks:

- high price;

- installation difficulty;

- high costs of electricity and the operation of such a system.

Another option that can be made is a combined solution. Such a solution will be especially effective if you improve the draw rate by using axial category fans at the entrance to the vertical air shafts. In this case, the air in the room is carried out by natural technology, and an appliance will be installed at the exit of the ventilation system, which causes a powerful airflow.

Design

Creating an effective ventilation mechanism in the type of buildings under consideration personally implies the need for certain calculations based on the following factors:

- the number of people living in the building;

- air in the building;

- the applied technique that forms an electrostatic field, for which reason the air composition changes and the aeroions disappear.

The project creation scheme will start from the air exchange calculations. This parameter will be key and it will give an opportunity to decide on the category of ventilation. If it belongs to the natural group, then the speed of movement of air flows will be somewhere around one cubic meter per hour.If it speaks of a supply and exhaust system, then the value will increase to three cubic meters per hour. Taken into account and the speed of movement of air masses. When designing the natural ventilation of the exhaust type in a house made of wood, it is assumed that the speed of transportation of air flows will be less than forced.

The higher this characteristic, the lower the section of the duct will be needed. As an example, we note that for the passage of 300 cubic meters of air per hour through the exhaust of the compulsory mechanism, a section of 16 by 20 centimeters or a diameter of twenty centimeters will suffice. Speaking of natural circulation, the cross section should be 25 to 40 centimeters or a diameter of 35 centimeters. The calculation should be made in accordance with the following characteristics:

- sanitary and hygienic requirements;

- frequency of air exchange;

- built area.

By the way, the multiplicity of air exchange will be directly related to the designation of the building. Kitchen ventilation in the type of buildings under consideration has a multiplicity factor of 1. At least, if we are talking about a normative value.If there is an error, then the final value should be rounded down.

It should be noted that it is possible to provide good air circulation without the involvement of specialists. But you need to be able to handle the tools. First, as already mentioned, all indicators of the ventilation system in a timber house should be calculated. It is necessary to understand how intense the air flow is, so that later you can calculate the necessary rate of air exchange. Usually enough values 150-200 cubic meters per hour. Now we determine the frequency of air exchange, that is, for how many times the complete air renewal will take place in the building.

To increase the efficiency of the ventilation system, the size of the building is taken into account., as well as the number of people who live in it on a permanent basis. For better air exchange, it will not be superfluous to supplement each room, including the toilet and bathroom, with intake valves. According to many, these devices make too much noise, which in fact is not entirely true. The reason is that they are equipped with a special material of noise-insulating type.In addition, the ventilation of such a house also means that it will often be necessary to personally install the intake valves of a homemade type. But it will be necessary only when the insulation is not in the duct, but only at the exit. You can choose the exhaust fan category with a power reserve, which will give him the opportunity to equip the premises of the house with the quietest devices.

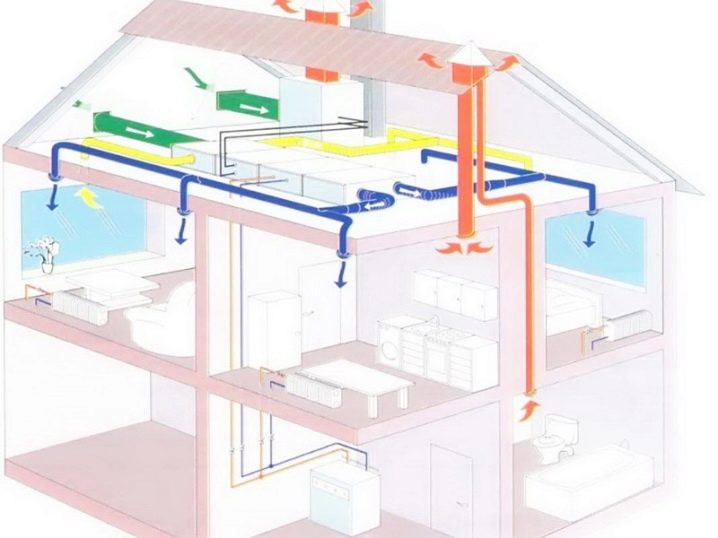

If desired, ventilation in such a building can be provided by a monoblock system with filters of various cleaning, as well as the possibility of low consumption of electrical energy. Usually this is achieved due to the presence of a built-in heat exchanger. In this case, be sure to consider the pattern of movement of air flows. Then the warm air, according to the laws of physics, will rise up, and the cold stay below. For this reason, floor and subfloor ventilation will be extremely important, and this should also be taken into account in the calculations that will be carried out.

It should also be aware of the norms of optimal air exchange, which are stipulated in the SNiP. These standards should be strictly followed. Only then ventilation can provide comfort in the house. If we talk specifically about the various rooms, it should be said that:

- in the toilet, the figure will be 30 cubic meters per hour;

- in kitchen 50, if an electric stove is installed, and 70 if a gas stove is installed;

- in the business premises, this figure is 15 cubic meters;

- in residential areas - 30;

- in the bathroom - 50.

How to set your own hands?

Now let's talk about how to make the ventilation in the house of wood with his own hands. Let us show this by the example of a 150 square meter building and using an air distribution mechanism with flexible ducts of corrugated type.

It is best to place the ventilation mechanisms in the attic so that, without damaging the roof, to make it as efficient as possible. And on the riser and under the ceiling in the ceilings to make hidden highways for the supply and exit of air on several floors of the building. You can, of course, make a conclusion through the wall, but in this case it was decided to do it in such a way as to preserve the beauty of the building.

The installation of the mechanism starts with the installation of distribution boxes for 10 sockets. The first box will be responsible for the air supply, and the second - for the conclusion.In addition, they will play the role of a silencer, since the boxes are wrapped with a two-centimeter layer of noise-suppressing material.

Now the installation of two silencers and a ventilation unit, equipped with a heat exchanger. Its wall can be easily dismantled for replacement of air filters. Now the marking is carried out and a passage is made through the bearing wall of wood into the street for mounting a branch, which will supply fresh air to the house.

The next step is to connect the air handling unit with silencers, insulate the supply and discharge air lines, and then install them. If the air intake would be made on the side of the house, then the removal of exhaust air should have been done through the roof. Then would be carried out installation of the so-called pass element. To do this, pass through the roof. After installing the fungus, a pipe is connected to it, through which exhaust air will be discharged. Just below, already in the house wall it is required to make a round hole for air intake, which should be closed by a ventilation grill.

The next step is to connect to the tap system. To do this, the connection is carried out with the insulated pipe of the installation and the passage in the roof. Now another warming outlet is being arranged nearby. He will be responsible for the supply and removal of air. Such a pipe can connect a kitchen hood with installation through a kitchen socket. The next step is to place and install the ceiling crusts. This should be done according to the ventilation project. Subsequently, during the finishing works, the ceiling can be made, and then the protruding portion of the boxes will be cut, after which special poppet valves will be installed.

When this is done, flexible ducts of corrugations should be prepared. It is necessary to identify the highway, measure the desired length and cut everything off exactly. Now we connect them with special rubber sealing rings and a set of strong latches. Nests that need to be left free, close the plugs. Fixing the duct, we get a ready highway. After that, we finish connecting all the boxes of the ceiling type and proceed to flat pass-through solutions through the wall.

For installation we customize them in thickness, attach and put the grid.If desired, you can change the lattice tilt, which will direct the air flow in a certain direction. The second part of the duct we bring to the junction boxes, which were mounted on the roof.

Each duct falls into its nest. That is, one part supplies air to the premises, and the second takes it. And so it should be for all highways. At this installation of the ventilation system in a wooden house is completed. The final touch will be the installation of disc valves after the completion of the finishing works and the outdoor ventilation grille, which must also be installed at the end of the works.

How to make ventilation in a wooden house, see the following video.