Air ducts for exhaust: varieties and installation

Any hostess seeks to make the kitchen in the house or apartment as comfortable as possible and equipped with all the necessary elements. There is no way to do without high-quality exhaust with an air duct - this technique ensures the rapid outflow of aromas emanating from freshly prepared food. Air ducts are recognized as one of the most important components of the ventilation system, which makes them relevant. Today we will take a closer look at such equipment, as well as learn how to install it correctly.

Differences between the kitchen exhaust system and ventilation

Many users ask themselves the question: what are the differences between kitchen exhaust systems and ventilation. Let's try to figure it out.

Nowadays, sanitary standards provide for the installation in different dwellings of the respective units, which are capable of providing high-quality air exchange of a specific frequency rate. In order to follow this requirement, in buildings with several floors, a ventilation system is being built up, which is a well thought-out network of canals that are located within the walls and provide discharge of emissions to the roof.

The ventilation ducts themselves are necessary for sending exhaust air outside the living space. Intake of fresh air occurs naturally, passing through the joints / crevices in the places of openings of windows and doors. However, you need to take into account that this system is not able to eliminate various odors, fumes and other similar things that often appear when cooking in the kitchen.

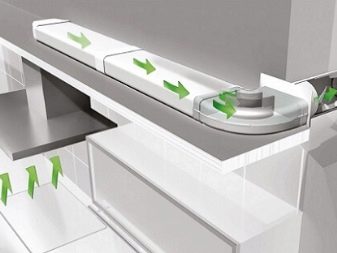

In order to get rid of such troubles, install a special ventilation system, working under compulsion. Otherwise, these parts are called hoods. These devices work a little differently. They absorb the fumes that come from the cooking surfaces, and then send them straight through a special exhaust duct with the help of an air duct.channel of the ventilation system.

Kinds

Air ducts designed for proper operation of the hood, are different. They are made of various materials, which always affects their performance and the final cost. Let us consider in detail which varieties of such aggregates exist, and by what parameters they are separated.

All types of air ducts are mainly divided into rigid and flexible types.

- Flexible air ducts It turns out to be located at various angles. If this is required, they can be stretched or constricted (of course, to the extent possible). However, it is necessary to take into account that a weakly elongated air outlet is more resistant to air flow. This is not the best effect on the overall effectiveness of the system as a whole. In most cases, these models are made of aluminum. The main disadvantage of such systems is that the corrugated box for them is not recommended to be made longer than 3 m, since any extra centimeter in this situation will reduce the performance by about 5-10%.

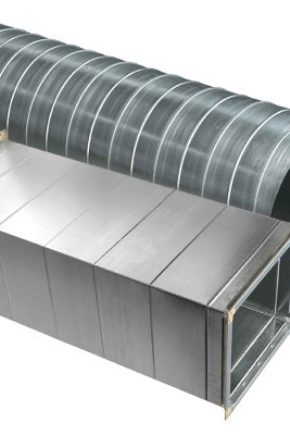

- Hard options distinguishes ease of assembly and a smooth surface of the inside.True, such models are more expensive, but their positive qualities justify their high price.

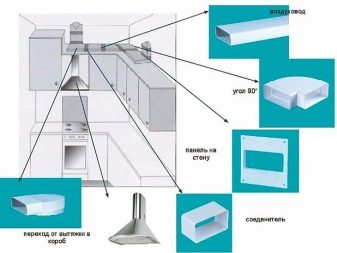

And also all air ducts are divided in their immediate form. There are several variants of such systems.

Consider in detail what are the air ducts for hoods.

- Rectangular and square. These types of air ducts are recognized as one of the most popular and are found with enviable regularity. Many owners choose them precisely because of the form, which allows you to place such equipment directly behind the kitchen cabinets. Thanks to this feature, it is possible to lay almost any trajectory from the exhaust equipment to the ventilation shaft. Rectangular copies will be the perfect solution for kitchens with any ceilings (meaning any parameter of height). In addition, these models can boast a good appearance.

But it should be borne in mind that rectangular ducting units usually have poor performance, especially when compared with other options.

- Flat. These duct options are one of the varieties of rectangular models.They have a very modest size and seem completely invisible.

- Rounded. Such types are more demanding - they can only be installed in rooms with high ceilings. This requirement is due to the large size of the equipment. If the outlet has a rectangular structure, it will be necessary to additionally use rectangular adapters with the appropriate cross section for rounded models.

- Oval. These instances have the same strengths and weaknesses as rounded specimens.

Of the listed options for air ducts should be distinguished flat rectangular models.

They are products with the following parameters:

- 110x55 mm - such options are required for extracts whose performance is no more than 300 m3 / h;

- 120x60 mm - suitable for equipping extracts whose performance level does not exceed 350 m3 / h;

- 204x60 mm - great for operation, coupled with high-performance units - up to 1000 m3 / h.

Materials

Air ducts for exhaust systems are made from different materials. So, one of the most popular is considered plastic. As a rule, they are issued with a rectangular or rounded section.So, the first ones are more aesthetic and neat, but round systems can boast a faster and simpler installation (no adapters are needed here to attach the air duct to the hood itself).

The main advantages of plastic structures are:

- a smooth surface in the interior, which is why fat and any contamination do not accumulate there;

- plastic parts will never rust;

- they have a very modest weight, so installing them is easier;

- similar constructions are fairly easy to assemble;

- when a plastic duct is working, there is no strong and annoying noise;

- such items are inexpensive.

The disadvantages of plastic systems are:

- in many cases, various adapters and connection details are required for their installation;

- These models “do not like” the effects of too high temperatures — under such conditions, plastic air ducts can release harmful substances.

The second most popular air duct systems made of aluminum. From the specified raw materials create pipes of these designs.

The main advantages of such species are recognized:

- easy and quick installation;

- Aluminum is a versatile and unpretentious material;

- such constructions seamlessly withstand the influence of high temperature values;

- such ducts are inexpensive.

As for the shortcomings of aluminum air duct systems, here it should be highlighted:

- not the most attractive appearance - as a rule, such equipment is “hidden” in special boxes or hidden inside kitchen cabinets;

- Aluminum itself cannot be called high-strength material - it is easily deformed and does not tolerate significant mechanical effects;

- since such a material has a high thermal conductivity, condensate is often accumulated in the room where aluminum ventilation is installed.

But there are also ducts of steel. As a rule, for the production of such structures used stainless steel or galvanized. As for simple home use, galvanized options have proven to be excellent here.

But It is worth noting that such models are no longer characterized by their former popularity. Every year, steel ducts are becoming less relevant.

The main advantages of such models are:

- a neat, even base, due to which the air flow rate does not become less, also dust and carbon accumulate in smooth pipes;

- steel duct seamlessly transfers high temperatures (under their influence, the products are not only not deformed, but also do not emit hazardous substances into the environment);

- These models are inexpensive.

Of course, the steel options have their drawbacks, which make them not the most popular:

- such parts have a more impressive weight (especially when compared with plastic ones), so installing them yourself is not always easy and convenient;

- for fixing on the walls for steel models we always need the most reliable fasteners;

- for high-quality sealing channels in such models will require special tools;

- if it is necessary to assemble an air duct that has an unusual structure, you may have to turn to additional cutting of metal pipes;

- when steel ducts work, they make loud noises, so you can forget about silent operation.

How to choose?

Choose air ducts should be based on several important criteria.

- The first thing you should pay attention to when choosing such a model is its manufacturer. It is recommended to give preference to high quality branded models.

- Acquire air exhaust systems in proven retail outlets or retail stores.

- Do not trust too low prices for similar products. Indeed, high-quality and reliable ventilation will not be too cheap, especially if it is made of good materials.

- Included with these products should be documents such as warranty card and manual. If there are none, then it is better to refuse to purchase an air duct in favor of another model.

- Choose products with sufficient power. If the air exhaust system will be low-power, then the exhaust simply does not cope with its main function, and the exhaust air will not leave the room in the proper amount.

- Do not forget about the design of such units - they must be merged into the interior.

In addition, choosing the ideal model, you need to remember what the main functions should perform the hood in the kitchen:

- quickly and in the required amount eliminate excess odors;

- make little noise;

- look attractive to fit into the decor of the kitchen.

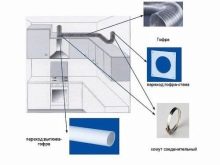

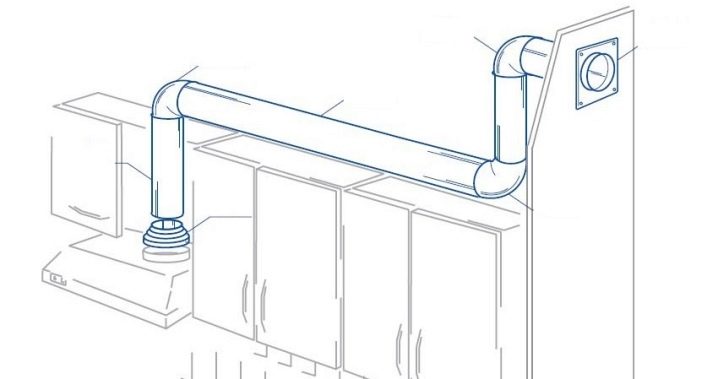

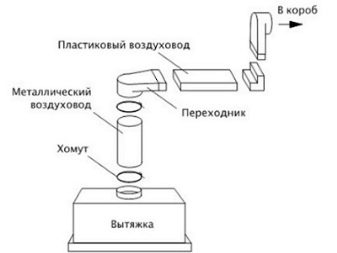

Installation

Installation of the duct is quite possible to do it yourself. The most simple in these matters are corrugated options. From just need to cut into pieces of the required dimensions, and then connect with the appropriate parts of the hood and the shaft in the kitchen. It is better to replace the simple ventilation grill with a special one - in which the connecting pipe is integrated. For mounting in this case, usually use special crimp clamps. For maximum reliability, the joints are treated with a sealing compound.

Air ducts from PVC raw materials are installed in the same way. The pipe is cut with a hacksaw into separate parts of the desired size, after which it is attached to the parts of the hood using adapters. The pipe should go deeper into the pipe by 50 mm (approximately). Mounts should be greased silicone compound.

If you put a high-power hood in the kitchen, you can have a reverse thrust effect. Simply put, there will be odors in the room, penetrating from the ventilation shaft.This applies to particularly powerful specimens, the level of performance of which ranges from 600 to 700 cubic meters of air per hour. In order not to face this trouble, you should fix the check valve.

These devices are performed in two main variations:

- filmy species;

- in the form of a disk of plastic on the axis.

Valve must be set vertically. Otherwise, it will be triggered by its own weight.

How to hide the technique?

Plastic parts are much easier to fit into different interiors, especially when compared with metal. However, they can spoil the appearance of the kitchen ensemble. That is why most owners prefer to simply close such items. You can do it correctly in different ways.

Consider the most common ones.

- Duct pipe permissible to hide under the stretch or multi-level ceiling. To this end, you need to collect a box of sheets of drywall - it will perfectly hide the entire system. However, this method can be addressed only if a serious repair is planned in the kitchen with a complete replacement of the ceiling base. If the hood is placed after the completion of the finishing works, then it will hardly be possible to hide it under the indicated structures.

- To disguise the air duct, they often buy a special PVC box (other materials are sometimes used). Such designs will play a decorative role, so usually they are selected to match the finish of the room. And also in similar boxes, you can additionally embed spotlights.

- Hood can be hidden in the furniture in the kitchen, if it is made to order. For this you need to notify the master of their preferences.

Air ducts are often built into the lockers or make them pull-out.

Useful tips

When selecting an air duct, one rule should be taken into account: the diameter of the exhaust pipe must correspond to the diameter of the hole, which leads to the mine. When choosing flexible options, you need to consider what you can do no more than 3 knees and bends.

It is recommended to install the hood in accordance with the direction of air movement. Otherwise, the service life of the device may be reduced, especially when it comes to plastic parts. Hood can be brought to the street. To this end, in the wall of the house it is necessary to make a hole of a suitable size. However, do not forget that before carrying out these operations you need to obtain permission from the BTI and utilities.

Experts recommend purchasing units, complete with covers that hide any of their disadvantages. In the collection of such models look much more aesthetic.

The worst option is a corrugated plastic pipe that performs the function of the air vent. It is better to give preference to the aluminum specimen. It is not recommended to place metal corrugations in the same ensemble with the kitchen set, made of natural wood. Such an interior will look disharmonious and even ridiculous.

Corrugated pipes during installation is recommended to stretch to the full length. Thus, it will be possible to avoid pollution in the inner part, which will provoke unnecessary noise during the course of the system operation. Today, many users prefer embedded hoods. In these models, the duct should be placed in the interior of the cabinet or fixed on its top.

In the next video you will find the installation of the air duct for the kitchen hood.